Leveraging its vast marine resources along with ample sunshine and wind, Vietnam has the potential to become Asia’s green hydrogen production hub.

This perspective was shared by Ms. Huynh Thi Kim Quyen, CEO of The Green Solutions Group, at a conference on Vietnam’s Hydrogen Energy Development Strategy through 2030, with a vision to 2050, organized by the Ministry of Industry and Trade on February 22.

Great Potential for Green Energy

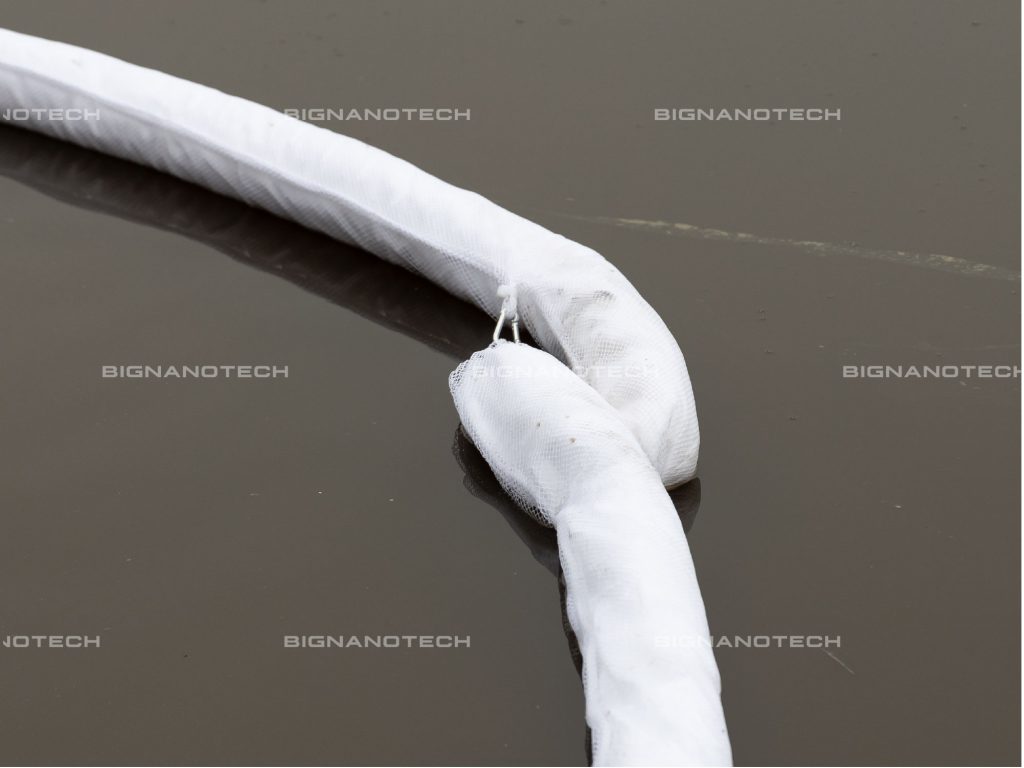

As the investor of the first green hydrogen project in Tra Vinh, Ms. Quyen highlighted that Vietnam’s 3,260 km coastline and abundant renewable energy sources—sun, wind, and seawater—are key components for sustainable green hydrogen production.

“This is a significant opportunity for Vietnam, with conditions not available in many countries globally. We have sunshine, wind, and seawater—endless resources that can create new fuel for humanity. However, turning this opportunity into reality requires strong government commitment and supportive policies for green hydrogen development,” said Ms. Quyen.

Discussing the $1.4 billion project in Tra Vinh, Ms. Quyen mentioned that before launching, the group spent two years researching green hydrogen and chose the globally prevalent alkaline electrolysis technology.

However, she pointed out significant challenges, including the need for comprehensive policy mechanisms, standards, investment in high-tech human resources, and technology. Additionally, green hydrogen production is costly, necessitating supportive policies to reduce costs and promote sustainable technology.

The CEO of The Green Solutions also mentioned the potential of green hydrogen production to sell carbon credits via green ammonia products, presenting a golden opportunity for Vietnam amid the growing carbon credit market. Thus, the Tra Vinh green hydrogen project has secured green financing from international financial institutions and banks.

Overcoming Challenges to Promote Green Hydrogen

“If Vietnam successfully builds and implements a green hydrogen industry based on its available opportunities and foundations, it could transition from an agricultural economy to a green industry, bypassing the heavy industry development phase,” said Ms. Quyen.

According to the plan, the project has commenced basic construction and received permits. Technical and specialized steps are being expedited to launch officially in Q3-2024, aiming to complete construction by 2026 and produce the first products by early 2027.

Vietnam’s Hydrogen Energy Development Strategy, approved by the Prime Minister on February 7, 2024, opens new development avenues for the country’s energy sector towards a green, clean, and sustainable future.

The strategy aims to develop Vietnam’s hydrogen energy ecosystem based on renewable energy, encompassing production, storage, transportation, distribution, domestic use, and export with a modern, synchronized infrastructure, contributing to net-zero emissions by 2050.

The strategy outlines solutions like diversifying funding sources and investment forms, attracting private and international partners, enhancing investment in science and technology, human resources, and applying market tools to promote green growth, low-carbon economy, and circular economy.

Minister of Industry and Trade Nguyen Hong Dien stated that to effectively implement the strategy and develop projects, the ministry will quickly draft and submit specific plans to authorities to achieve the set goals and solutions, ensuring consistency and synchronization.

Simultaneously, the ministry will focus on revising, supplementing, and issuing new regulations and policies related to hydrogen energy, contributing to completing the policy and legal framework. This includes monitoring and expediting hydrogen energy projects, promptly addressing any challenges.

Source: Tuoi Tre Newspaper.