With the increasing scale and frequency of industrial production activities today, the amount of waste oil released into the environment is substantial, severely affecting the quality of water and air. Therefore, the production of an effective solution to address this issue is highly anticipated. To meet these expectations, industrial oil filter fabric has been developed with the ability to thoroughly clean oil, even very thin oil films.

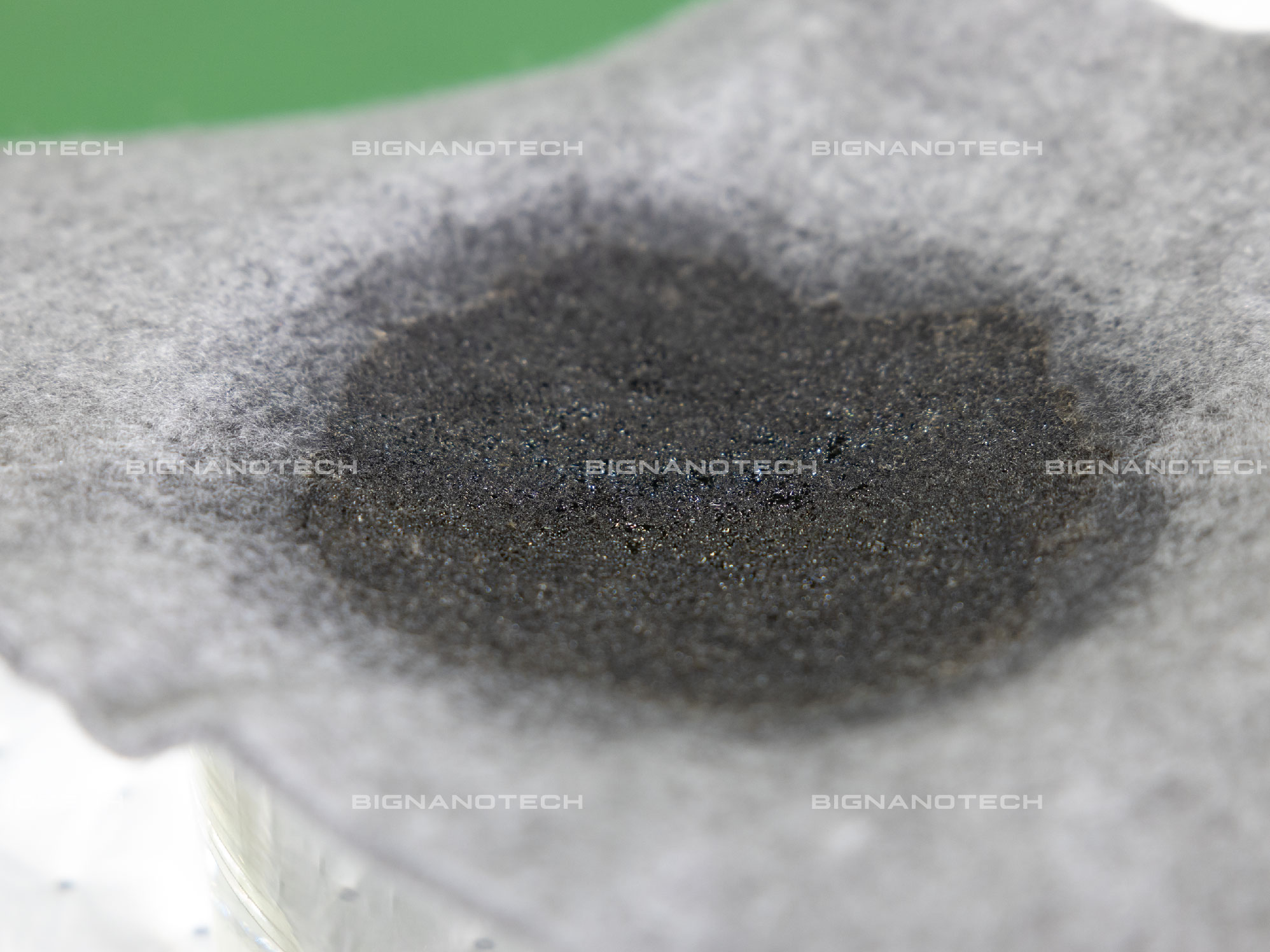

Description of N-FIBER oil filter fabric

The oil filter fabric is used to filter spilled oil and oil mixed in water at wastewater drains, solution conduits, and other points before being discharged into the environment. The product can completely separate various types of oil from oil-contaminated water, whether it’s surface oil or emulsified oil. This is an optimal environmental and infrastructure protection solution for businesses that often discharge oil-containing liquids.

The oil absorbent fabric is made from 100% polypropylene with Japanese Nano fiber spraying technology, optimizing its filtration capability. The product is non-corrosive, and the oil will not leak from the roll.

Usage instructions

Using industrial oil filter fabric is incredibly simple and convenient. Users just need to place the oil filter fabric of suitable size at the wastewater drain, filtration system, three-compartment tank, etc., and let the oil-contaminated water flow through the fabric to filter out the oil and grease.

Currently, industrial oil filter fabric is used as a replacement for chemical-based oil-contaminated water treatment systems, providing superior efficiency and high safety, and being human and environmentally friendly.

Technical specifications

- Size: According to customer needs

- Specific weight: 0.5kg/m²

- Oil filtration and retention capacity: 20 times its own weight (depending on the type of oil)

- Can withstand a flow rate of up to 250m³/hour

Applications of oil filter fabric

- Rainwater filtration: Filter oil and oil-contaminated substances from ditches, conduits, ponds, wastewater pits, manholes, and water drains.

- Supporting oil/water separators: Water from oil separators often still contains a thin oil film. Oil filter fabric is used to thoroughly filter this oil film in the final step before discharging the water into the environment.

- Oil filtration/erosion prevention for canal and pond banks: Serves four simultaneous purposes: prevents oil films or oil in water from contaminating the soil banks; prevents oil-contaminated soil from leaching into the water; prevents erosion and landslides of canal/pond banks; absorbs and retains oil in the fabric fibers to allow natural degradation over time.

- River/sea bank oil filtration: Used as a barrier to prevent oil spills in rivers/seas from reaching the shore, easy to handle even in rocky or uneven water bottoms.

- Oil and grease-containing wastewater filtration: Particularly effective for filtering oil and grease in wastewater and oil collection pits without clogging the flow.

- Oil spill response: Used as a filter for oil-contaminated water, replacing oil absorbent pads on the water surface. This product performed excellently during the oil spill response in the Gulf of Mexico in the USA. Used as a curtain barrier at ports to absorb floating oil films.

- Oil collection: Oil absorbed into the fabric fibers can be easily separated using mechanical methods (wringing, pressing, centrifugation…) and can be reused multiple times until the fabric becomes frayed or punctured.

For more information on products and industrial cleaning solutions, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com