Coating is an

essential product for life

Material protection

Protective coatings safeguard the structural integrity of materials such as wood, metal, etc., from the impact of water, mold, and insects. The coating also helps reduce material shrinkage and expansion, prevents corrosion and oxidation, thereby enhancing the durability and lifespan of the material.

Weather impact resistance

Various weather-resistant coatings help protect surfaces from temperature fluctuations, UV rays from sunlight, rain, snow, and wind. This is crucial in maintaining the appearance and physical properties of the material.

Chemical resistance

Chemical-resistant coatings are used in industrial environments to shield surfaces from the effects of chemical substances such as acids, alkalis, and other corrosive agents.

Scratch and impact resistance

Coatings also help protect surfaces from mechanical impacts such as scratches and impacts, thereby safeguarding products or structures from damage and reducing the risk of accidents.

Enhanced cleanability

Some advanced technology coatings can resist dirt and are easy to clean, aiding in maintaining a clean appearance for structures and reducing sanitation efforts.

Aesthetic improvement

Coatings bring aesthetic appeal to products and materials. They not only make the surface smooth and shiny but also contribute to creating diverse colors and patterns, making the product more attractive.

Applications of high technology Coating

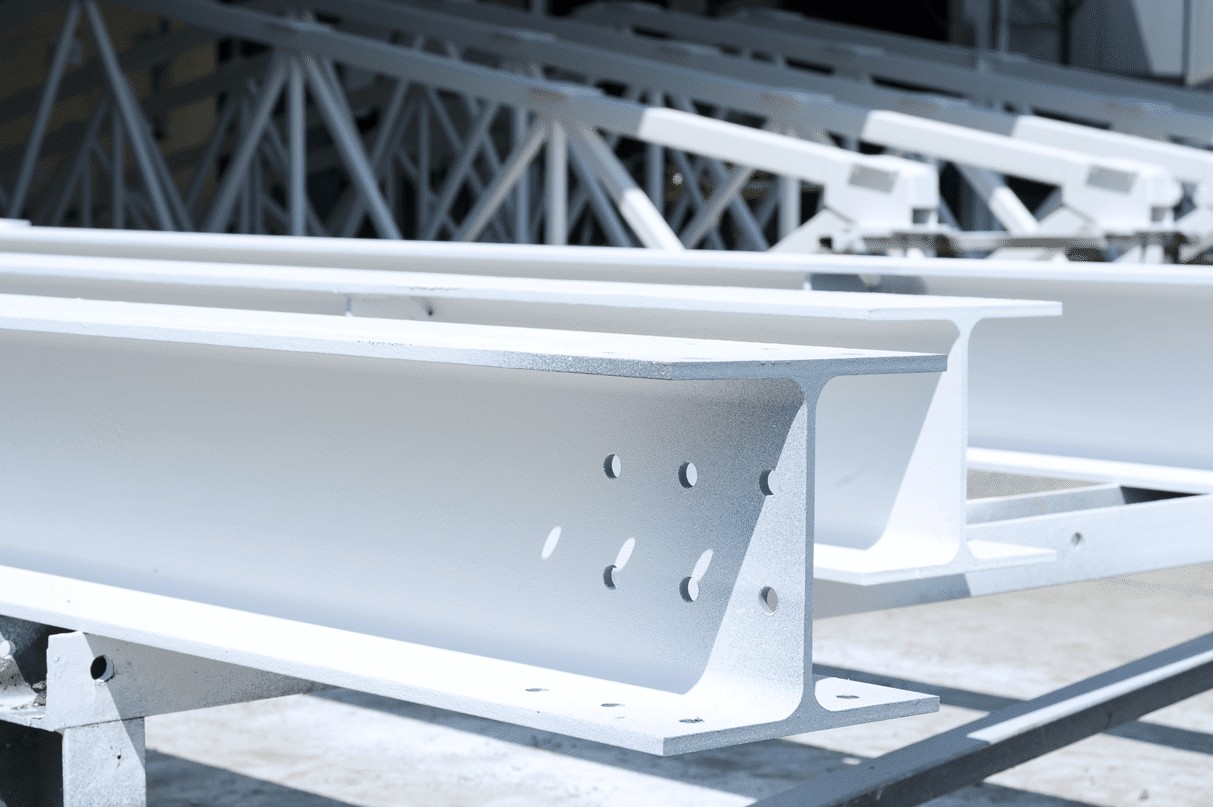

Industrial and Construction Sector: Protecting and Enhancing Durability for Steel, Aluminum, and Other Metal Structures Against Environmental Impact, Corrosion, and Chemical Agents.

Fire-Resistant Coatings: Improving the fire resistance of building structures and reducing smoke toxicity. Serving projects that require fire prevention and firefighting measures.

Wood Industry: Waterproof coatings prevent water infiltration and increase the durability of wood materials. Protecting and beautifying wooden furniture, interior furnishings, and other wood products.

Automotive Industry: Scratch and abrasion-resistant coatings maintain the surface of cars looking fresh and shiny. Protecting car surfaces from the effects of weather, water, and dirt adhesion.

Maritime Industry: Anti-fouling coatings resist moss and parasites to maintain optimal performance and reduce growth on the ship's hull. Protecting the ship's hull from the impact of seawater, corrosion, and chemical agents.

Aerospace Industry: Corrosion-resistant and waterproof coatings on aircraft structures enhance durability and longevity. Protecting surfaces from temperature effects and chemical agents in the aerospace environment.

Oil and Gas Industry: Waterproof coatings prevent water intrusion and reduce the impact of chemicals in the oil and gas environment. Protecting pipelines and oil and gas equipment from corrosion and the harsh environmental conditions.

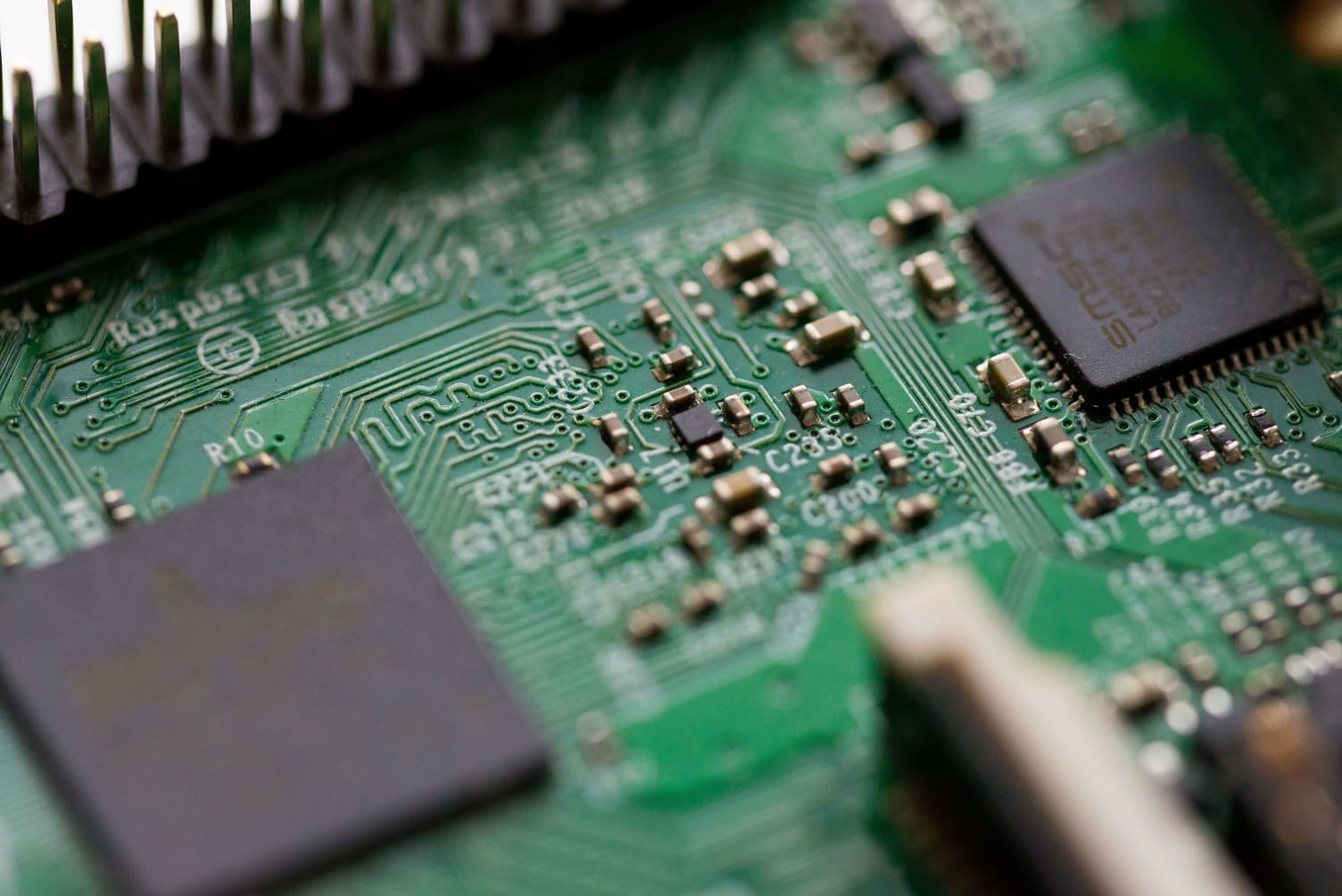

Electronic Industry: Anti-static coatings protect and enhance the safety of electronic components. Protecting the surfaces of electronic devices from environmental impact and chemical agents.

Medical Industry: Antibacterial coatings increase the safety of medical equipment, protecting them from the spread of bacteria and viruses. Safeguarding the surfaces of medical devices from corrosion and the impact of medical chemicals.