A. HARMFUL EFFECTS OF OIL SPILLS

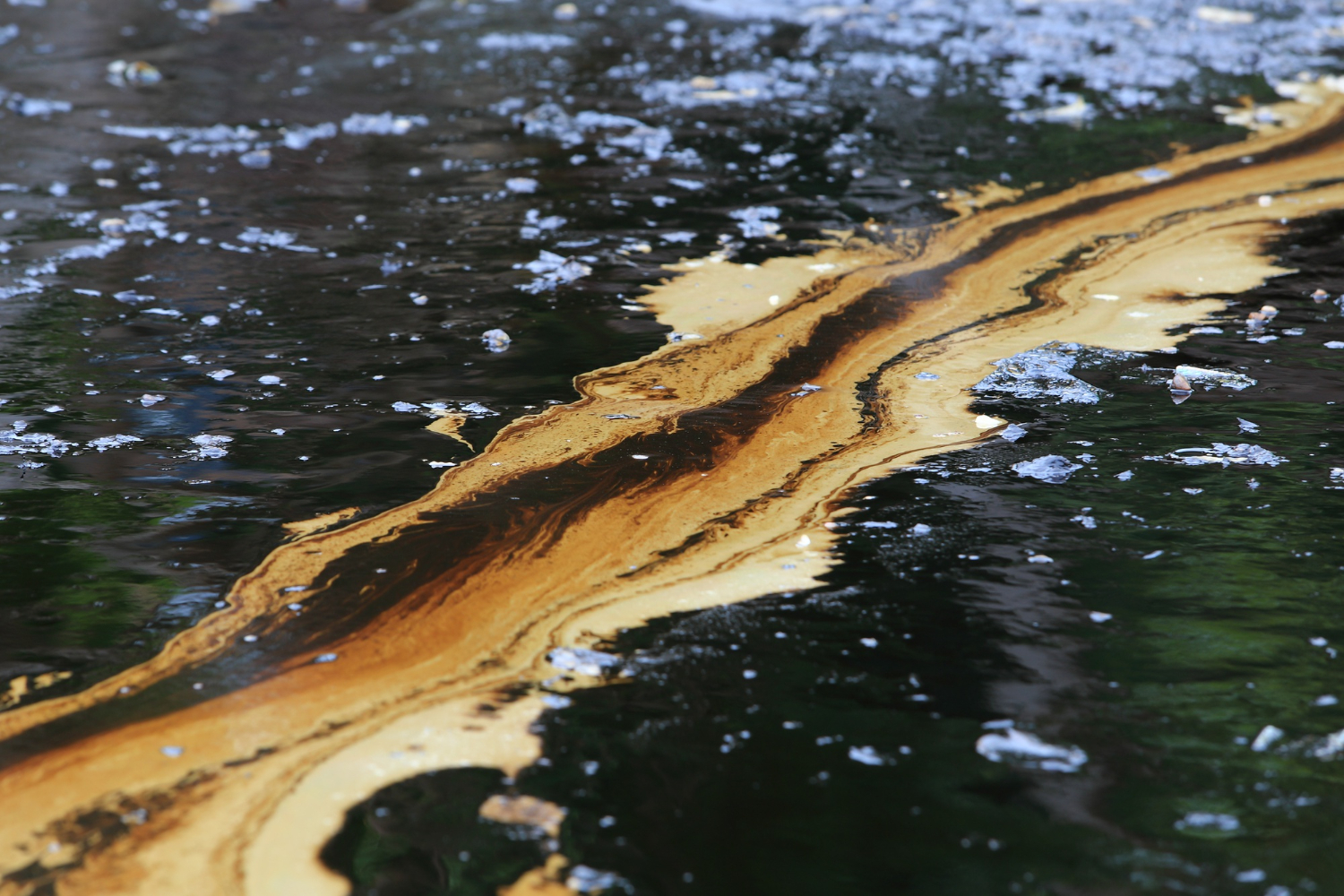

Oil pollution and spills cause numerous direct and indirect impacts on ecosystems and riversides in various aspects. When oil spills reach the shore, they hinder many economic development activities.

1. Environmental Impacts of Oil Spills

- Water Pollution:

Research by scientists and environmental experts indicates that when the concentration of petroleum and its products in water reaches 0.5mg/l, oil starts to emit an unpleasant odor. The chemical indicators of water change drastically when the concentration of petroleum and its products exceeds 100mg/l.

The presence of oil films on the water surface reduces oxygen exchange between the air and water, decreasing dissolved oxygen levels and increasing CO2 levels, causing a drop in water pH. Since oil films are dark-colored, they have a high solar heat absorption capacity, leading to increased water temperatures. The easily soluble components in oil, mainly petroleum ethers, are highly toxic to aquatic life.

- Disrupting the life activities of organisms:

Oil covers the cell membranes of lower organisms like plankton and protozoa, disrupting osmotic pressure regulation, causing mass deaths of lower organisms, juveniles, and larvae. Oil adhering to organisms’ bodies hinders respiration, metabolism, and movement.

Oil concentrations in water as low as 0.1mg/l can be lethal to plankton, the first link in the aquatic food chain. For bottom-dwelling organisms, oil pollution significantly affects juveniles and larvae. Oil absorbed by adult organisms reduces their usability due to the oil odor.

Fish are severely impacted by oil spills, with effects depending on the solubility of harmful compounds in oil. Oil sticking to fish reduces their usability due to odor, and fish eggs can be rendered nonviable by oil contamination. Oil pollution can cause mass fish deaths due to decreased dissolved oxygen in the water.

- Potential toxicities in the ecological environment:

Oil spills indirectly affect organisms by impeding oxygen exchange between water and the atmosphere, promoting the accumulation of toxic gases like H2S and CH4, raising pH levels. Oil sediments accumulate in the sediment, increasing oil content and causing toxicity to bottom-dwelling organisms.

- Impact on Fisheries:

Decline in fishing and aquaculture productivity due to reduced fishery resources in oil-affected areas. Fish and seafood often acquire an oil odor, making them unsellable.

- Hindrance to Shoreline Economic Activities:

Oil spills drifting with surface currents, waves, and tides adhere to rocks and coastal areas, causing aesthetic degradation and unpleasant odors for tourists, reducing local tourism revenue.

2. Impact on Economic Activities:

Aquaculture is one of the crucial economic sectors in coastal and riverside communes. These areas use river and sea water directly for aquaculture. Therefore, in the event of an oil spill contaminating the water source, these farming areas will be the first to be affected. Shrimp and clams are highly sensitive to polluted water, so the damage level will be significant.

When oil infiltrates the ponds, it gradually accumulates in the organisms’ bodies until it reaches a certain threshold, leading to death (initially, shrimp show signs of sequential death, and after a few days, they die en masse). Another cause is that the oil spill depletes the water’s oxygen supply for the aquatic life, leading to death.

It should also be noted that since most local residents invest a considerable amount of capital in aquaculture, an incident will severely impact their economic livelihoods if not promptly addressed.

3. Impact on Natural Resources and the Environment:

Oil toxicity varies daily based on pollution concentration. Although the most toxic components of oil can dissolve in water and evaporate quickly, all aquatic organisms can accumulate oil even at very low concentrations. Oil accumulation in sediments and sand in stagnant waters poses long-term ecological risks.

The survival of flora and fauna depends on natural instincts and external factors. During spawning seasons, organisms become more sensitive to oil. Recovery of species depends on the timing of the oil spill, recovery efforts, and the accumulated oil content in each species. Species with rapid growth rates recover quickly, while slow-growing species may take years to fully recover.

B. EFFECTIVE SOLUTIONS FOR HANDLING OIL SPILLS AT THERMAL POWER PLANTS

To mitigate oil spill risks at thermal power plants, strict environmental protection and safety measures must be implemented. Enhanced monitoring and control, adherence to oil use regulations, and treatment of oily wastewater are essential.

Thermal power plants must have comprehensive emergency response plans to handle oil spills promptly. Effective oil spill management technologies are crucial for reducing pollution risks and enhancing industrial hygiene at plants and downstream areas.

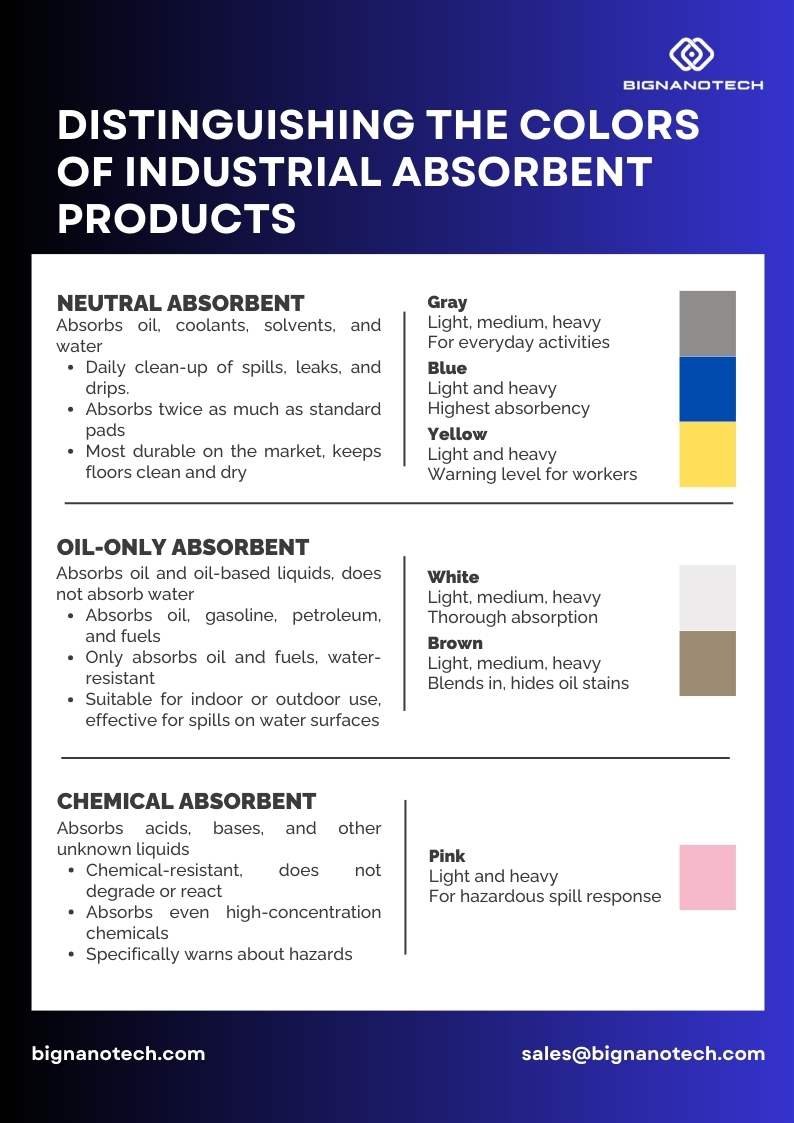

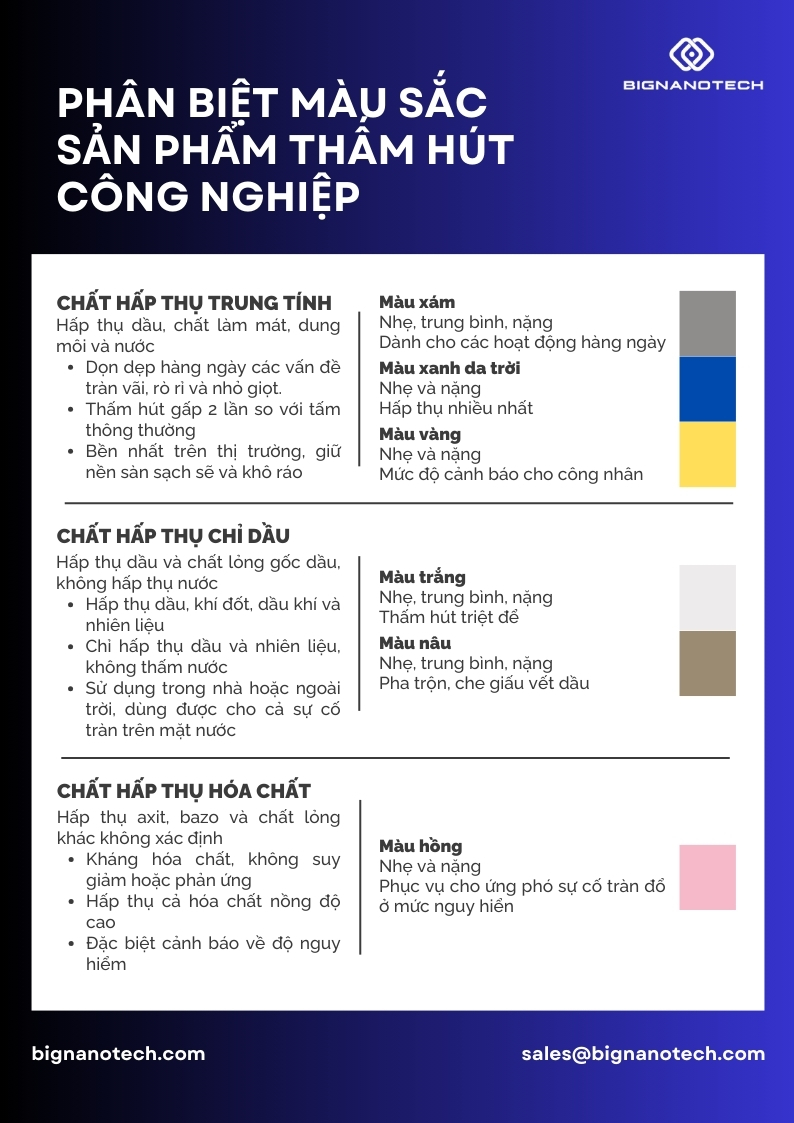

Some products suitable for spill handling, industrial cleaning and oil pollution prevention at thermal power plants include:

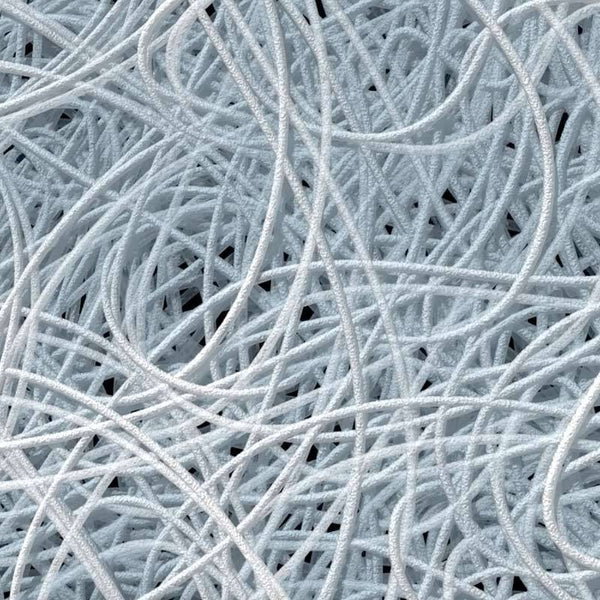

- Oil Absorbent Pads: Ideal for cleaning machinery and absorbing spilled oil on floors or water surfaces.

- Oil Absorbent Booms: Isolate and absorb oil spills, preventing the spread to water or land.

- Cleaning Powder: Cleans oil stains on surfaces without secondary cleaners.

- Biological Oil Degrading Powder: Absorbs oil in soil and decomposes it into plant-friendly fertilizer.

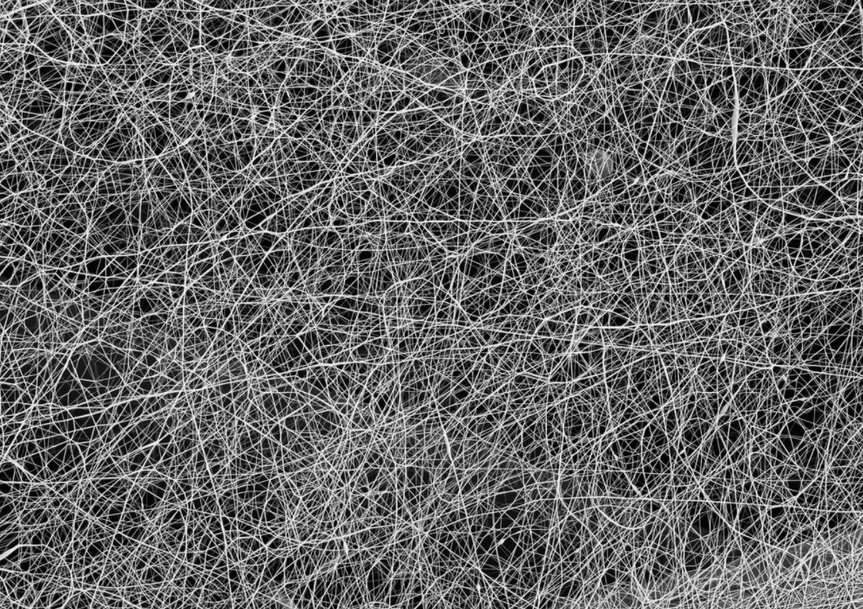

- Oil Absorbent Cotton: Suitable for handling oil in narrow, hard-to-reach areas.

- Spill Kit: For responding to and managing medium to small-scale oil spills.

In conclusion, oil spills and leaks at thermal power plants are significant threats to the environment and human health. Addressing these issues requires proactive management by plant authorities to protect worker health and the environment.

For product consultation, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com