Chemical spills and leaks are a potential risk at textile dyeing facilities due to the continuous demand for chemicals. To ensure the safety of people and the environment, it is crucial to develop and implement procedures for handling chemical spills. Below are some basic requirements for textile dyeing facilities.

1. Legal Requirements

Chemical Law of 2007

- Decree 113/2017/NĐ-CP; Unified document dated March 9, 2020

Environmental Protection Law of 2020

- Decree 08/2022/NĐ-CP

- Decree 45/2022/NĐ-CP

Fire Prevention and Fighting Law (Amended) of 2013

- Decree 136/2020/NĐ-CP guiding the Fire Prevention and Fighting Law and the amended Fire Prevention and Fighting Law (Effective from January 10, 2021)

- Decree 144/2021/NĐ-CP regulating administrative penalties in the field of fire prevention, firefighting, and rescue

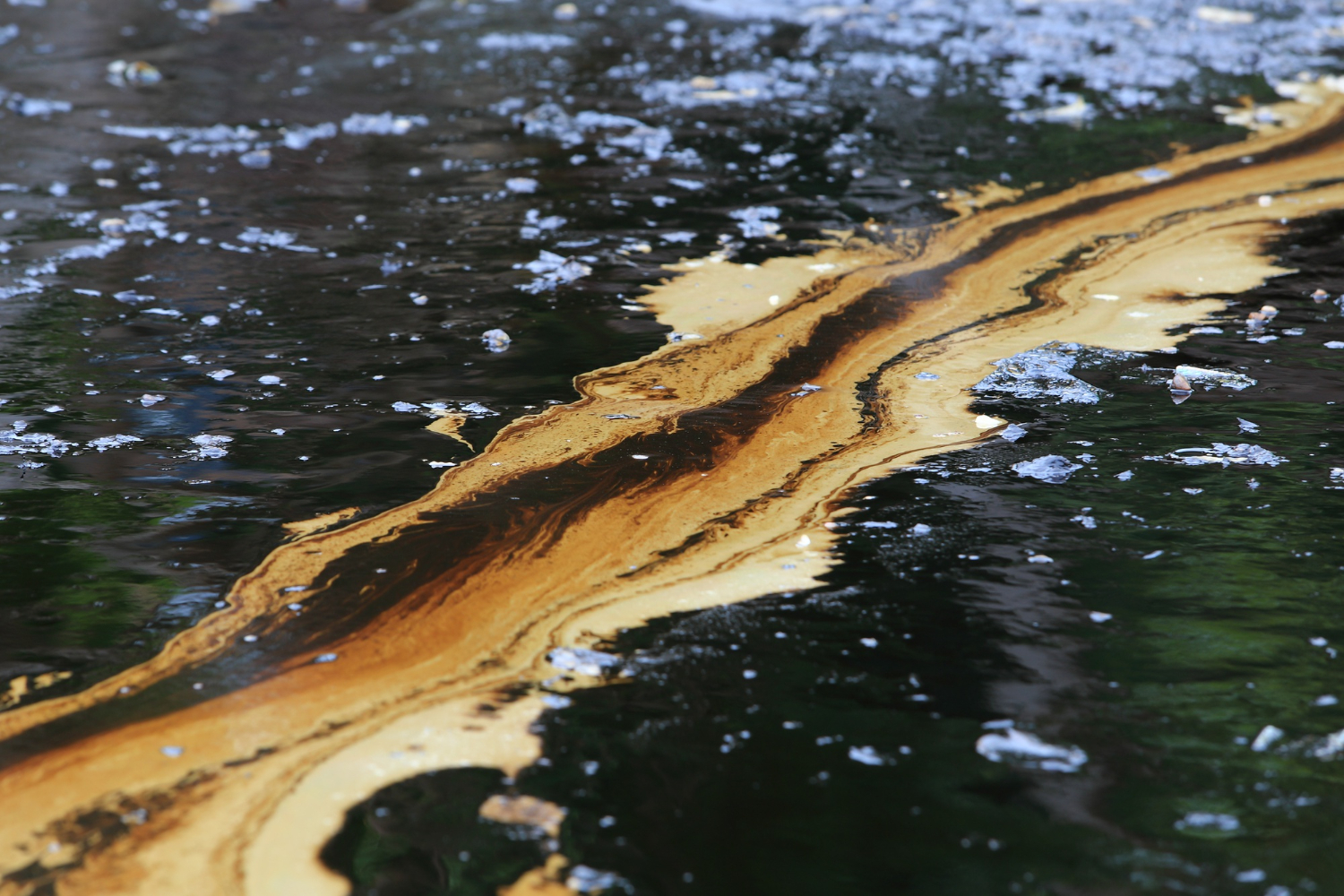

2. Risks of Chemical Emissions from Textile Dyeing Facilities

- Sizing agents.

- Alkali chemicals.

- Detergents and washing agents.

- Alkylphenol Ethoxylates (APEOs).

- Dry cleaning chemicals.

- Bleaching agents.

- Stabilizers.

- Optical brighteners.

- Dyes (colorants).

- Dye auxiliaries.

- Printing auxiliaries: padding, coating, bactericidal, antistatic, etc.

- Flame retardants.

- Water/oil repellents: fluorinated compounds, paraffin, silicone-resistant, etc.

- Preservatives.

- Anti-slip agents.

- Softening agents.

3. Classification of Chemical Spill Severity

Chemical spill incidents can be classified into four levels to establish appropriate response plans and measures.

Level 1:

- Incident confined to a small area in the warehouse/workshop, the person who discovers it can handle it immediately with response equipment or by simple repair actions.

- Does not pose a risk to people, property, or the environment.

- Relatively small spill amount: <100L.

Level 2:

- Incident has the potential to spread to other areas in the warehouse/workshop.

- Slight risk to people (minor injuries).

- Can be controlled by the on-site response team.

- Relatively small spill amount: <1000L.

Level 3:

- Incident can spread to warehouse/workshop/adjacent structures within the factory.

- Causes damage to people (could lead to severe injuries or death), the environment, and factory property.

- Beyond the control of the on-site response team.

- Relatively large spill amount: >1000L.

Level 4:

- Incident can spread to adjacent factories in the industrial park.

- Causes significant damage to people (serious injuries or death), the environment, and property within and outside the factory.

- Beyond the control of the on-site response team.

- Relatively large spill amount: >1000L.

4. Predicting Risky Points and Incident Scenarios

- Fire and explosion.

- Chemical spills.

- Liquid ammonia.

- Exhaust emissions.

- Wastewater.

Refer to the 8 Steps for Responding to Chemical Spills for textile dyeing facilities here.