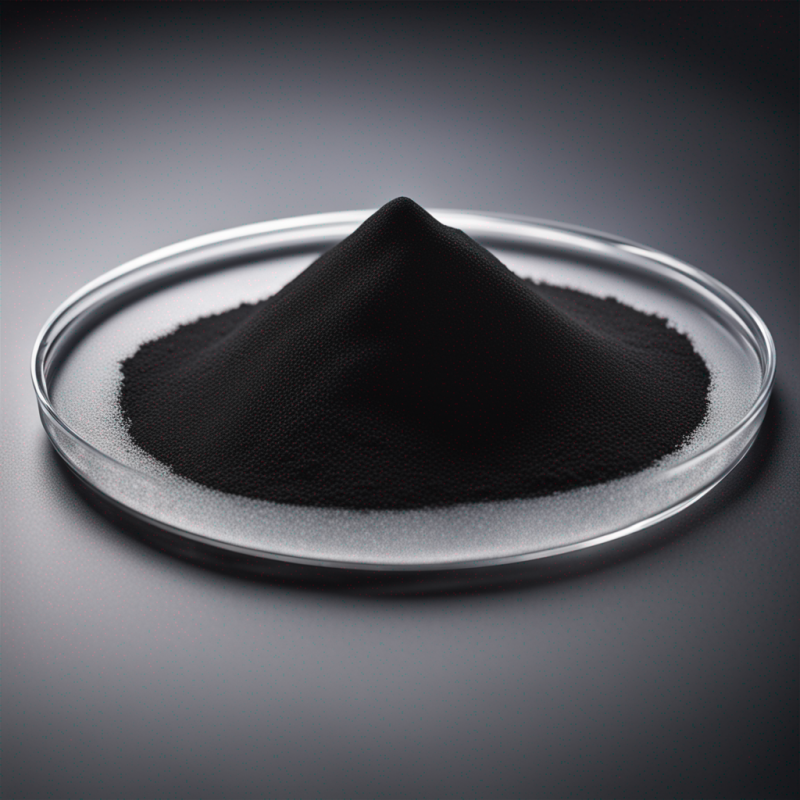

In recent years, graphene powder has attracted the attention of the scientific and industrial communities due to its versatility and diversity. Graphene, a form of carbon material, just one atomic layer thick and with special physical and electrochemical properties, has opened up a range of potential applications in various fields.

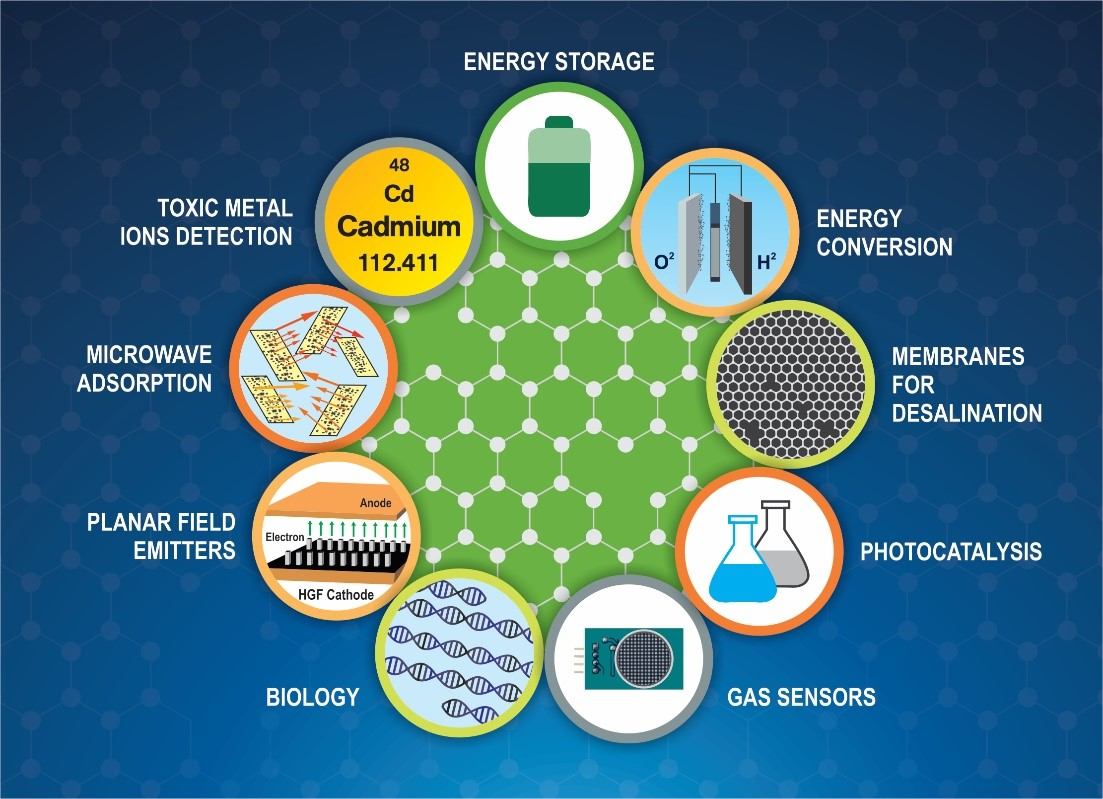

1. Electronics Applications: Graphene powder is widely used in the production of electronic components such as integrated circuits, sensors, and electrodes. Its excellent electrical and thermal conductivity make it an ideal material for high-end electronic applications.

2. Battery Technology: Graphene is also used to enhance the performance and lifespan of batteries. Its good conductivity can improve charging efficiency and reduce charging time, as well as decrease the self-discharge rate of batteries.

3. Light-Interacting Materials: Due to its excellent light absorption and reflection properties, graphene powder is used in the production of light-interacting materials such as photo-reactors, touch screens, and optical applications.

4. Mechanical Materials: Graphene also exhibits excellent mechanical properties, with high hardness and strength. Therefore, graphene powder is used in the production of mechanical materials such as composites and reinforcement materials to improve their mechanical properties.

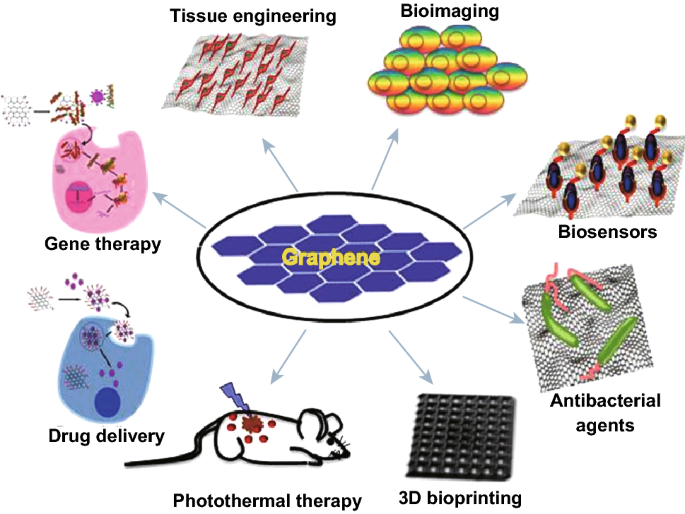

5. Medical Applications: Graphene powder can be used in medical applications such as diagnostic devices and medical sensors. Its ability to interact with biological molecules makes it a potential choice for medical applications.

Currently, BIGNANOTECH is manufacturing and distributing G-Matrix Sophis Graphene Powder suitable for various diverse applications, such as:

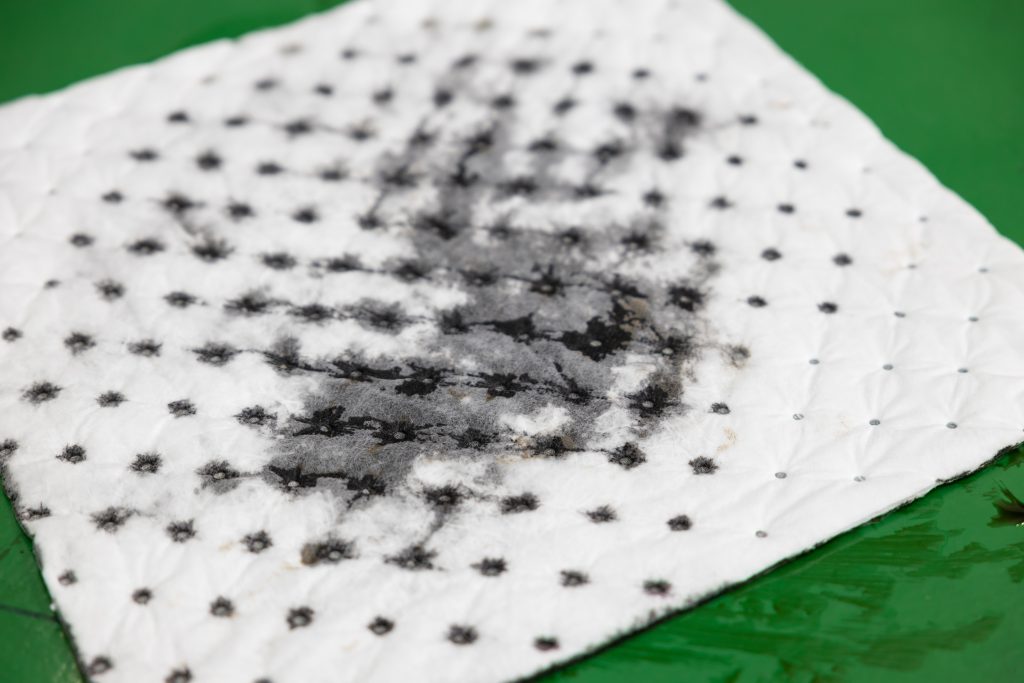

- Mixing to create multi-application composites such as anti-oxidation corrosion coatings for metals, thermal insulation coatings, anti-static coatings, electromagnetic wave shielding, water repellent coatings, and UV protection.

- Use as additives for paint coatings, rubber compounds, ceramics, alloys…

- Additives for battery electrodes and batteries to enhance charging and storage capabilities.

- Base material for nano-materials applied in adsorbents, catalysts, and solar panels.

We are also seeking partners to develop this potential field together.

For product consultation or collaboration opportunities, please contact:

BIGNANOTECH Company

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com