A. What to do after purchasing a chemical spill response kit

Preparing action plans and backup materials for oil and chemical spills in industrial settings is crucial. It is essential to ensure workplace safety and protect the environment for your business. Once you have spill response kits, you need to understand how to use them effectively to manage spills efficiently.

First, anticipate areas where chemical spills or leaks might occur. Ensure the spill response kit is stored near these areas, where it is easily visible and accessible in case of an emergency.

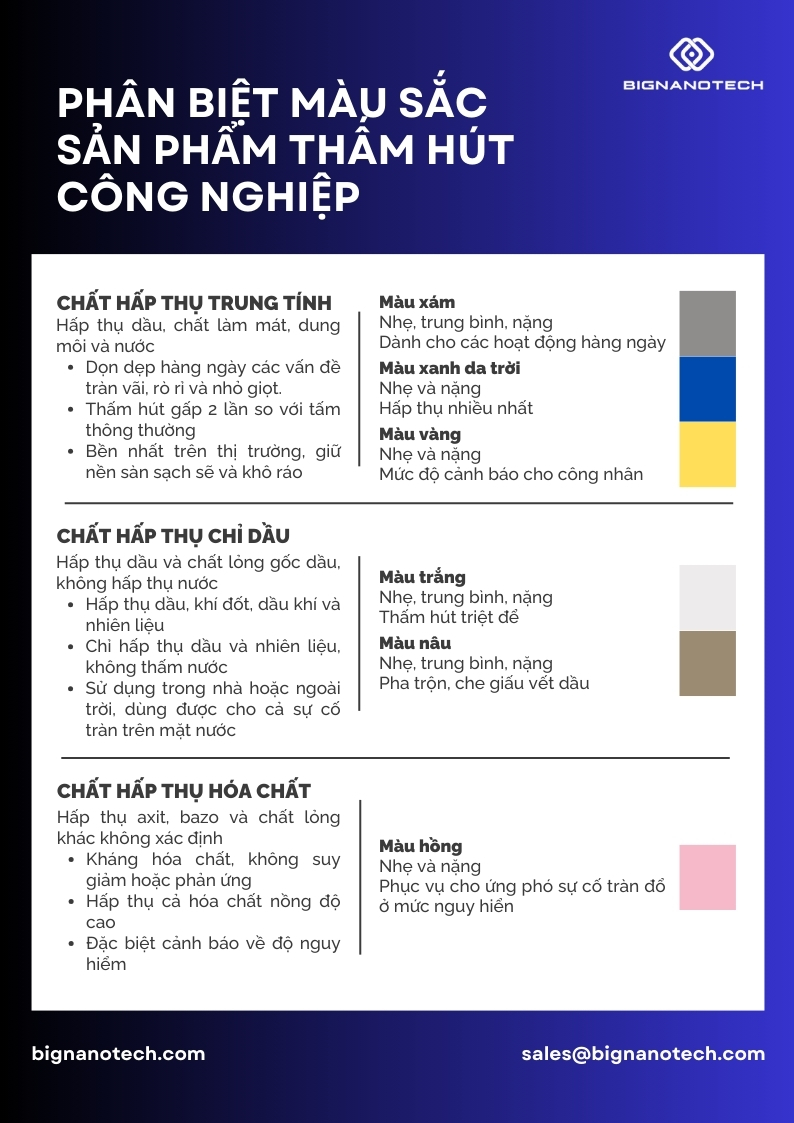

Next, open the chemical spill response kit and familiarize yourself with the products and instructions included. Typically, a chemical spill response kit contains:

- Absorbents in bagged form

- Chemical absorbent booms

- Absorbent pillows and pads

- Personal protective equipment (gloves, safety glasses, etc.)

- Shovels, brooms, and waste bags

- Hazardous waste labels

- Instruction cards, warning barricades, etc.

(The included products may vary depending on the kit’s capacity and customer requirements.)

B. Basic chemical spill response instructions

1. Protect the spill area

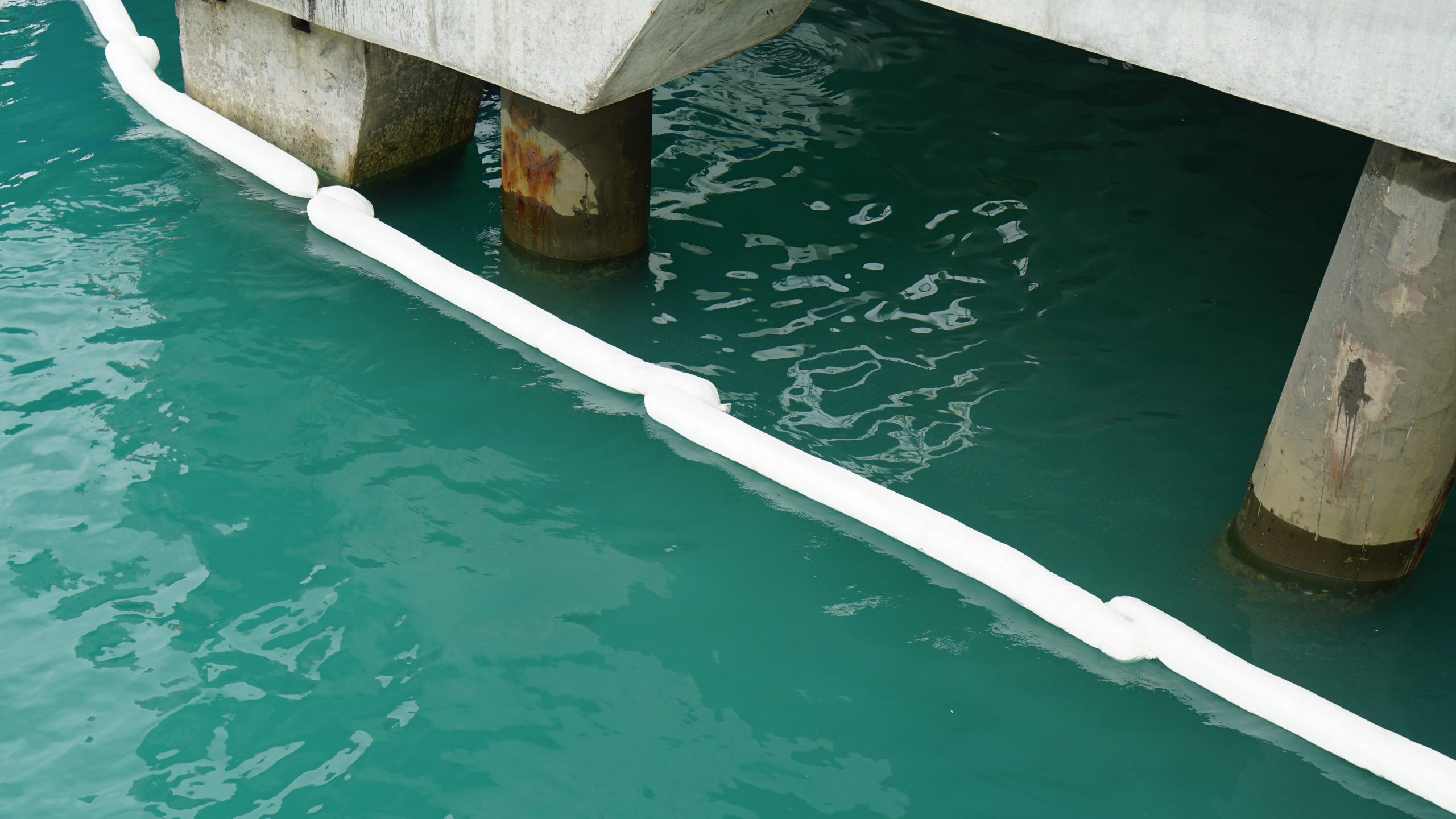

First, create a barrier around the outside of the spill area using absorbent booms or absorbent pillows. This will isolate the spill location, reduce spreading, and minimize the impact on the environment and people nearby. The booms and pillows will both contain and absorb the spilled chemicals.

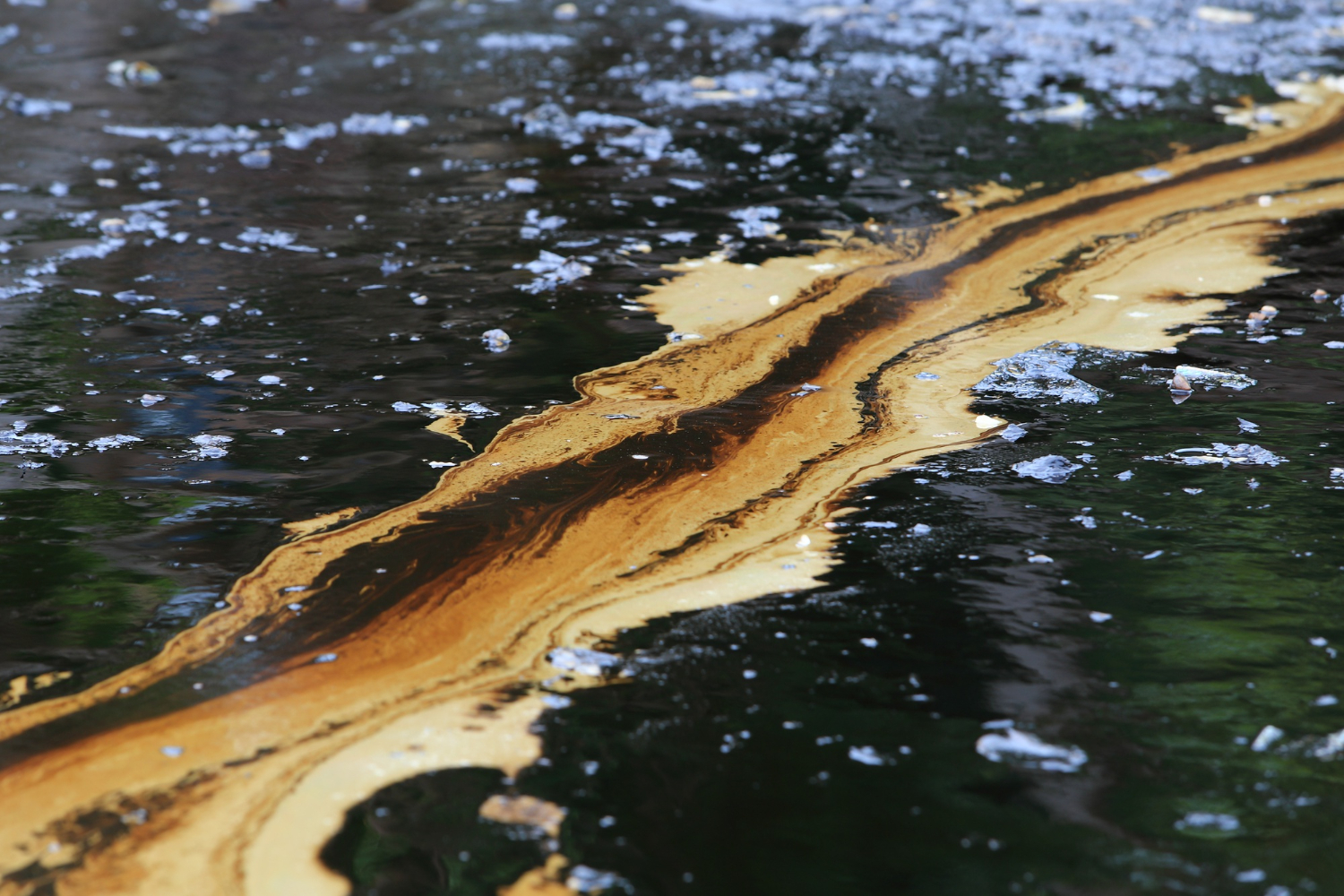

For spills on water, use oil absorbent booms to create a barrier preventing the spill from spreading and affecting the environment. Multiple layers of booms can be used to form an effective barrier depending on the terrain and severity of the spill.

2. Stop the source

When a chemical spill occurs, first stop the source (close valves or taps, upright overturned containers, contain the spill source, etc.). Stopping the source will reduce the impact and scale of the spill, providing a safer working environment for the responders and allowing for quicker, more effective action.

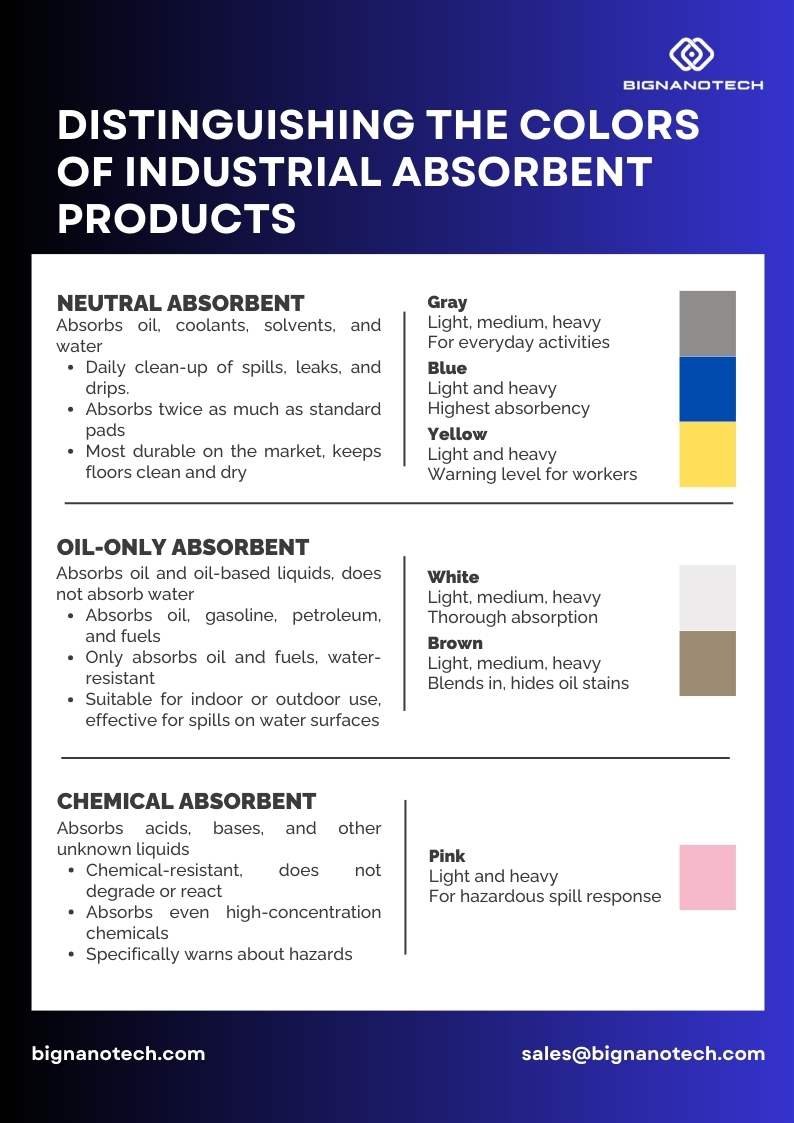

3. Clean up the chemicals

Use appropriate absorbents from the kit (chemical absorbent pads, oil absorbent pads, oil absorbent cotton, chemical absorbent pillows, cleaning powder, etc.) to absorb the spilled liquid. Use chemical/oil absorbent pads to quickly absorb, cover maximum spill area, and collect any residue left on the surface. Use pillows to absorb larger volumes of liquid.

Cleaning powder helps absorb large quantities of liquid and is excellent for removing spills in cracks and crevices on uneven surfaces. Especially when using absorbent powder:

- Sprinkle the absorbent powder from the bag onto the surface of the spilled liquid. Sprinkle from a low and close distance to avoid dust and product waste.

- After a few minutes, the powder will absorb and encapsulate the spilled liquid or neutralize acids.

- Use a stiff broom to sweep back and forth until the surface is dry and clean. Typically, 1 kg of absorbent can absorb 4 liters of oil. If there are still oil traces on the surface, it means the absorbent is oversaturated. Additional absorbent is needed.

4. Handle used products

Collect solid waste (booms, pads, pillows, absorbent powder soaked with spilled liquid) using a shovel and gloves into a container or bag, then dispose of it according to local Environmental Protection Agency regulations. The appropriate waste handling method should be applied depending on the type of chemicals absorbed. Remember to label hazardous waste bags properly.

For product consultation, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com