The development of hydrogen energy is a crucial strategy in the context of global energy transition, especially when many countries are aiming for net-zero emissions. Vietnam is no exception, with specific goals and a clear roadmap to develop hydrogen energy by 2030 and with a vision to 2050.

Decision No. 165/QD-TTg of the Prime Minister approved the strategy for the development of hydrogen energy in Vietnam. Accordingly, by 2030, the production capacity of hydrogen from renewable energy and other processes with carbon capture will reach about 100 – 500 thousand tons/year, increasing to 10 – 20 million tons by 2050. The goal is to contribute to the national commitment to net-zero emissions.

Development Perspective

The development of hydrogen energy must be based on ensuring continuity and consistency with national energy development strategies and plans, while being dynamic and open to adapt to the global energy transition context and situation.

Development along the Value Chain

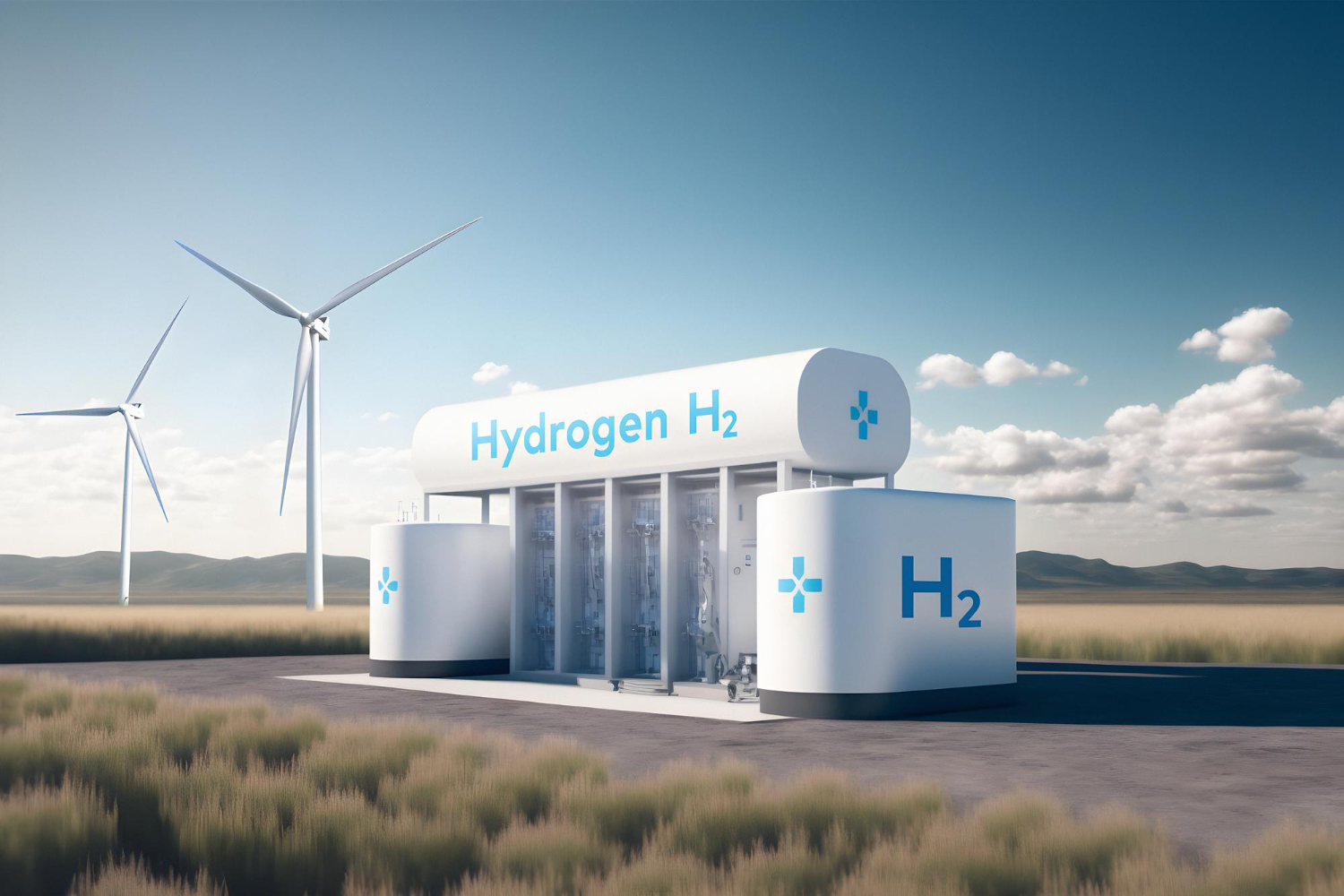

Hydrogen energy will be developed along the value chain from production, storage, transportation, distribution to utilization, contributing to energy security and greenhouse gas emission reduction. This promotes the development of a green economy, a circular economy, and a hydrogen economy.

Reasonable Development Roadmap

The development of hydrogen energy will be linked to the energy transition roadmap in Vietnam, closely following global technological development trends, especially in the use of renewable energy to produce green hydrogen. Efficient, sustainable, and economical utilization of national resources will serve both domestic demand and export needs.

Encouragement of Usage across Economic Sectors

Hydrogen energy will be encouraged for use in all sectors of the economy to reduce greenhouse gas emissions, with appropriate preferential policies for high-emission sectors such as power generation, transportation, and industry.

International Cooperation

Vietnam will enhance international cooperation to share experiences and knowledge in developing the hydrogen energy ecosystem, effectively leveraging international community support.

General Objective

The aim is to develop a hydrogen energy ecosystem based on renewable energy, including production, storage, transportation, distribution, domestic use, and export with synchronized and modern infrastructure. This ensures energy security, meets national climate change targets, and promotes green growth.

Specific Tasks and Solutions

- Hydrogen Energy Production:

- By 2030: Apply advanced technology in green hydrogen production and carbon capture/use (CCS/CCUS).

- By 2050: Master advanced technology in green hydrogen production, achieving a production capacity from renewable energy processes and other processes with carbon capture of about 10 – 20 million tons/year.

- Hydrogen Energy Utilization:

- By 2030: Develop the hydrogen energy market, and trial hydrogen-based energy in some sectors.

- By 2050: Promote the application of green hydrogen energy and hydrogen-based fuels in all energy-consuming sectors.

- Policies and Legislation:

- Develop and supplement regulations on renewable energy development policies in the amended Electricity Law.

- Create mechanisms and legal frameworks for enterprises to transition to hydrogen energy production and use.

- Investment and Finance:

- Research and invest in pilot projects for small-scale clean hydrogen energy production.

- Diversify and effectively mobilize various sources of capital, both domestic and international, for hydrogen energy development.

- Science and Technology:

- Update global technological advancements, enhance research, application, and transfer of hydrogen energy production technology.

- Encourage enterprises to invest in research and development, and promote innovation in the hydrogen energy sector.

- Training and Human Resource Development:

- Implement tasks and solutions in training, environmental protection, international cooperation, and communication to raise awareness about the benefits of the hydrogen economy.

Conclusion

Vietnam is gradually implementing a strategy to develop hydrogen energy, aiming for a sustainable and greener future, while contributing to the goal of net-zero emissions by 2050.

To discuss and cooperate in developing this technology, please contact us

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com