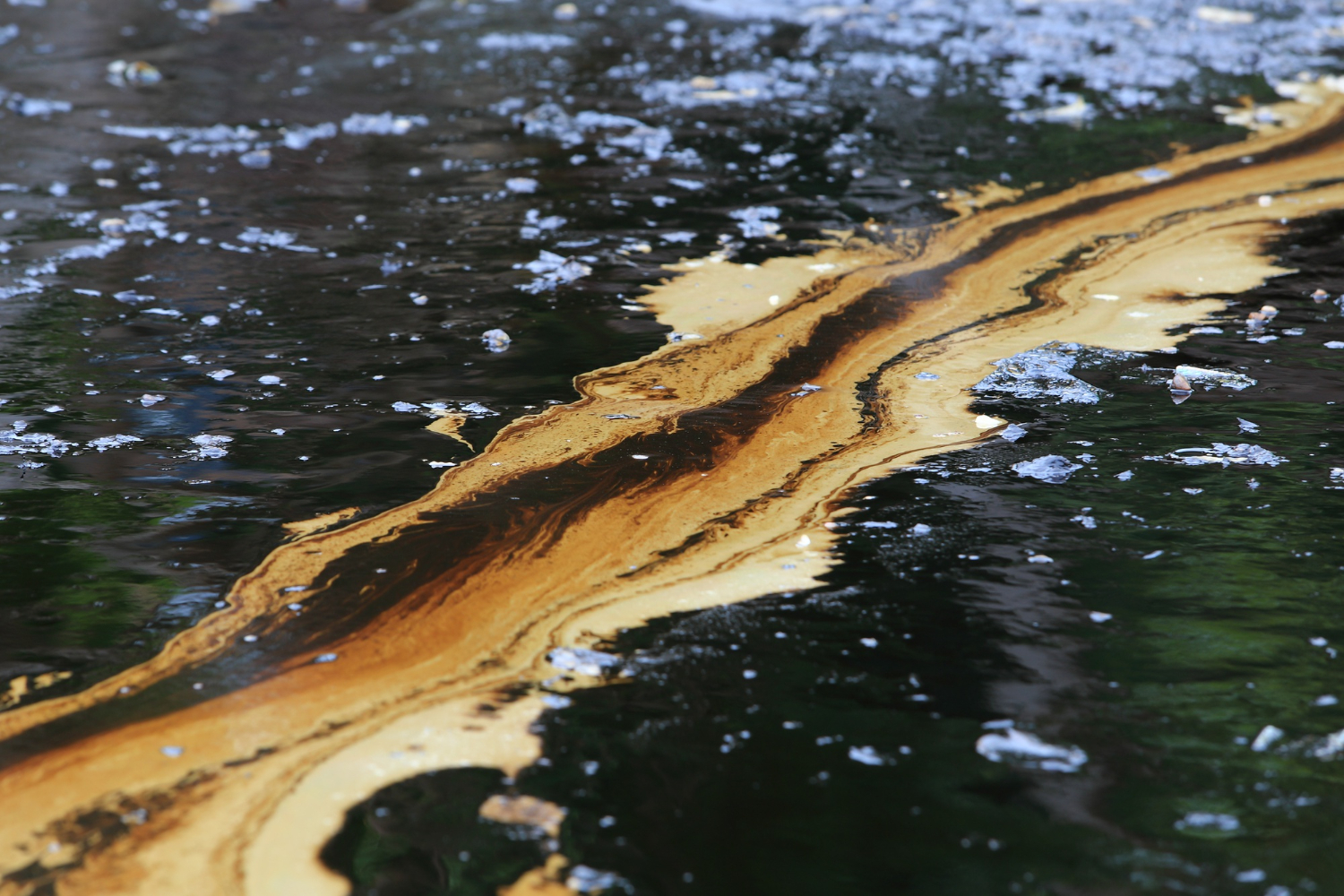

N-POWDER SORBENT is primarily composed of natural oil-absorbing materials that are safe, human-friendly, environmentally friendly, and fully biodegradable. This product is designed for collecting, cleaning, and absorbing oil generated during manufacturing processes or oil spill incidents.

Technical specifications

- Oil absorption capacity: 1.5 – 3.5 times its weight.

- Moisture content when packaged: 10 – 15%.

- Surface material resistance: 10^6 – 10^9 (Ω/m^2).

Key features

- Rapid absorption of various spilled oils, ensuring clean and dry surfaces.

- Isolation of absorbed liquids without releasing them back into the environment, thus preventing secondary pollution sources.

- High practical absorption capacity, significantly reducing disposal costs.

- Minimization of vapor emissions from volatile spilled solutions prone to combustion.

- Natural cellulose composition, environmentally friendly.

- Non-corrosive, non-toxic to human health, flora, and fauna, and safe for the environment.

Simple and safe to use.

Applications

- Used in areas prone to oil leaks or spills in factories, manufacturing workshops, oil spill incidents, or household use.

- Applied for absorbing and cleaning spilled gasoline and oil at petroleum ports, oil import-export stations, retail gasoline stations, oil tankers, mechanical maintenance and repair workshops, warehouses, land construction projects, ports, dredging operations, and all locations where gasoline, other hydrocarbon solutions are spilled and need treatment.

Instructions for use

Direct application:

- Step 1: Cut open the bag, sprinkle N-Powder Sorbent powder around the spilled oil area to prevent spreading.

- Step 2: Continue sprinkling N-Powder Sorbent powder to cover the entire oil-slicked surface.

- Step 3: Use a stiff brush/broom to sweep back and forth until the absorbent powder has soaked up all the oil, leaving the surface clean and dry.

- Step 4: Dispose of the absorbed powder in designated containers.

Note:

- Do not use N-Powder Sorbent for absorbing and cleaning chemicals.

- If oil stains are still visible on the surface, it means the absorbent powder has reached saturation; additional powder should be applied to thoroughly clean the area.

- No need to rinse with any secondary chemicals.

For consultation or purchases, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com