Ensuring the safe and efficient operation of energy plants requires regular and meticulous inspection, cleaning, and maintenance activities to meet technical requirements.

Industrial maintenance and cleaning are routine activities conducted annually at hydroelectric and thermal power plants, including specific tasks such as:

- Cleaning, maintenance, inspection, testing, and calibration of plant equipment systems.

- Addressing and rectifying operational defects as they occur.

- Repairing, adjusting, or replacing equipment that does not meet technical specifications.

Management departments at production plants must devise cohesive and effective solutions to successfully fulfill these tasks, ensuring safe and productive operations.

How to optimize cleaning costs and effectiveness in industrial cleaning at plants?

Some hydroelectric and thermal power plants still rely on traditional cleaning materials such as rags, leftover fabric, or scraps, which are unable to completely absorb industrial oils and chemicals, thus leaving residues on surfaces. Additionally, these materials cannot be reused after handling spills. Therefore, implementing innovative methods in maintenance and cleaning processes at plants to optimize efficiency and costs is essential.

Across large-scale production plants and industrial zones worldwide, the utilization of advanced technology products for thorough cleaning is increasingly prevalent. Specialized products ensure optimal cleaning for all surfaces while saving labor and resources. Commonly used materials provided by BIGNANOTECH for machinery and production areas include:

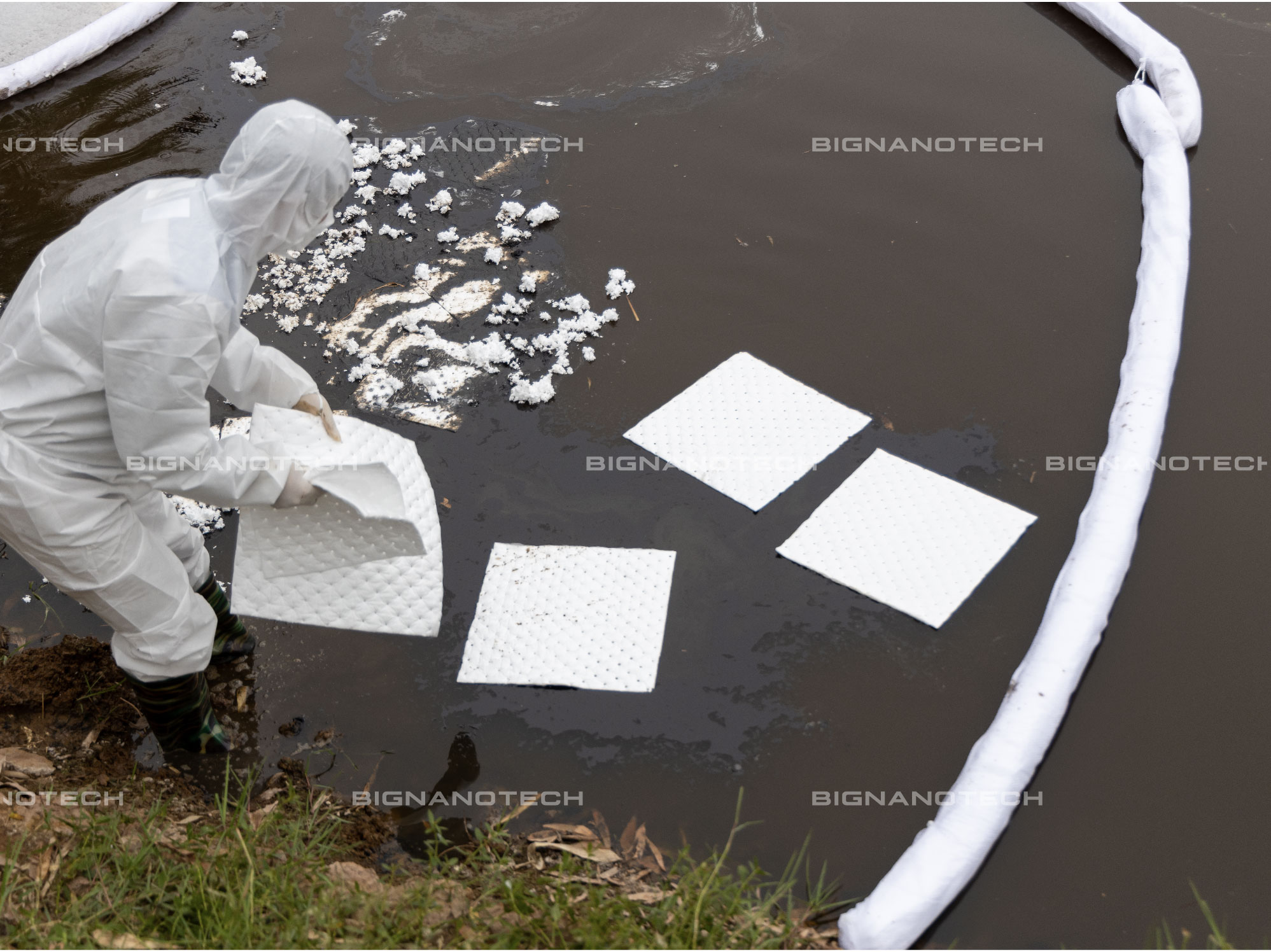

- Oil Absorbent Pad: Swift and efficient cleaning of oil spills both on land and underwater, selectively absorbing oil without absorbing water.

- Oil Absorbent Pillow: Ideal for placing in areas with continuous oil leaks, with a high capacity to absorb large amounts of oil.

- Oil Absorbent Sock/Boom: Prevents oil spills from spreading into the surrounding environment during large-scale spills, aiding in effective containment and response.

- Oil Absorbent Powder: Completely removes liquid residues like sticky oil from hard surfaces without requiring secondary cleaning agents.

- Biological Oil-Degrading Powder: Decomposes oil contaminants in soil and transforms them into organic fertilizers beneficial for soil.

- Oil Filter Fabric: Helps separate oil and impurities from water, ensuring the safety of discharged water into the environment.

In Vietnam, Big Nano Technology is the sole company specializing in manufacturing specialized materials for industrial cleaning of oil and industrial chemicals. The company provides the most efficient and optimal solutions for industrial cleaning during plant operations, industrial zones, and handling oil/chemical spills across diverse environments. With exclusive advanced Nano technology from Japanese experts, BIGNANOTECH products offer rapid absorption and optimal retention capacity, delivering superior cleaning efficiency and cost savings compared to conventional methods.

For consultation and solutions regarding industrial cleaning, please contact:

BIGNANOTECH Co., Ltd.

Hotline: (+84) 879 808 080 – (+84) 868 939 595 – (+84) 943 867 099