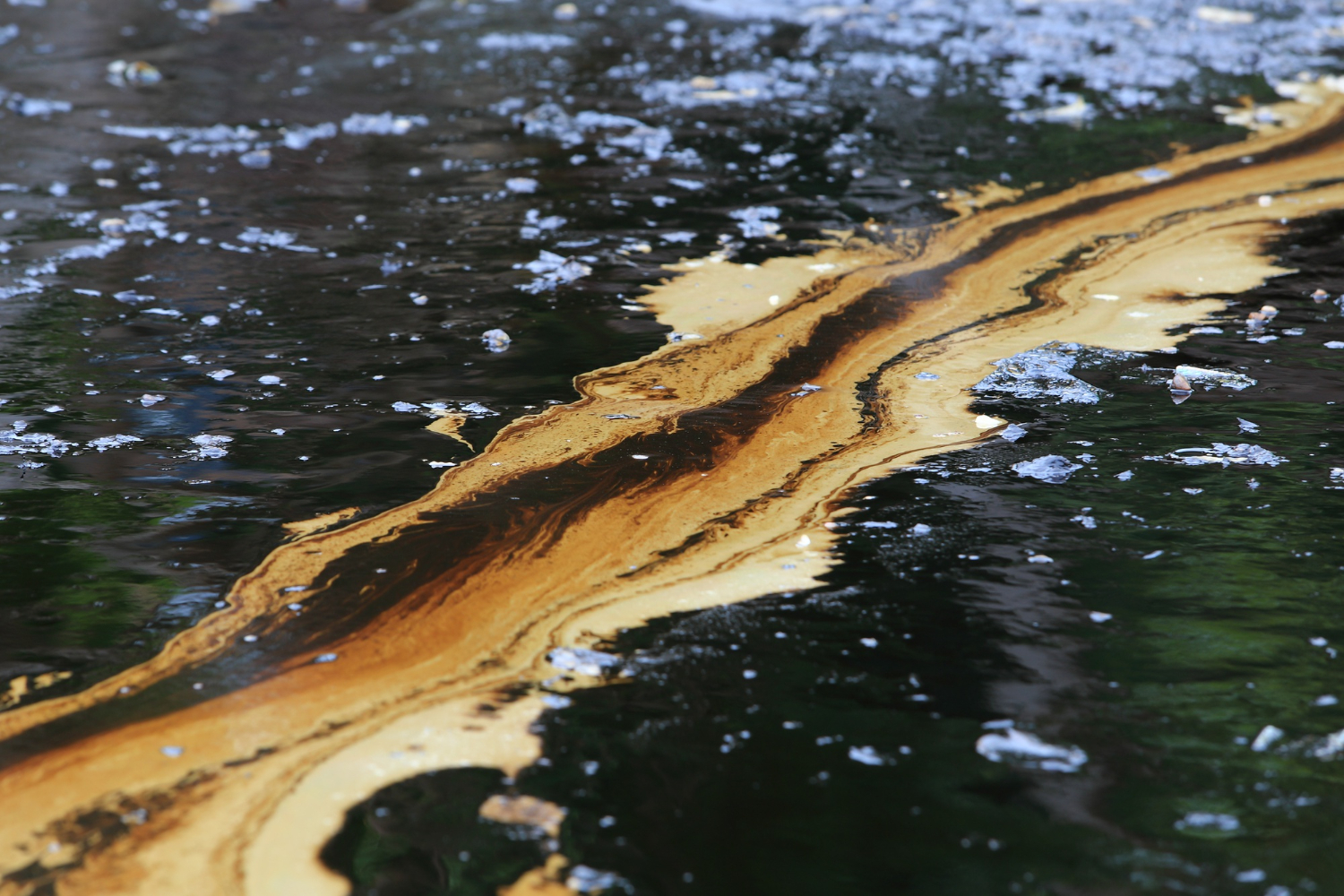

In recent years, the world’s oceans have been facing an increasingly severe and expanding problem of oil pollution. Each passing day, oil spills continue to inflict numerous negative impacts on marine ecosystems and coastal economies.

Rising number of incidents and their larger scale impacts

Reports indicate a growing number of oil pollution incidents globally, with particularly alarming figures in recent years. From oil spills resulting from maritime accidents and offshore drilling activities to illegal oil dumping, these events occur with alarming frequency, leaving significant environmental consequences.

Environmental devastation and ecosystem impacts

Oil pollution causes a multitude of adverse effects on marine life. Oil coating the ocean surface and dispersing in water leads to suffocation and toxicity for fish, seabirds, and other marine animals. Coral reefs, vital ecosystems of the sea, also face critical endangerment when covered by oil layers, resulting in ecosystem imbalance, declining populations, and genetic alterations due to pollution.

Negative impacts on coastal economies

Beyond environmental concerns, the impacts of oil spill incidents on economies are also highly concerning. Coastal communities reliant on fisheries and tourism face significant losses as polluted waters render seafood inedible and affect both the scenery and experiences of tourists. The costs and resources required for cleanup and restoration are substantial, which could otherwise be allocated to nature conservation and sustainable development programs.

Global response

To address this escalating issue, governments, environmental organizations, and stakeholders in the environmental sector are actively engaging in exchanges to devise solutions to control marine oil pollution and mitigate its impacts. Improved regulations, strict enforcement measures, and advancements in extraction, processing, and cleaning technologies are being deployed to safeguard our oceans for future generations.

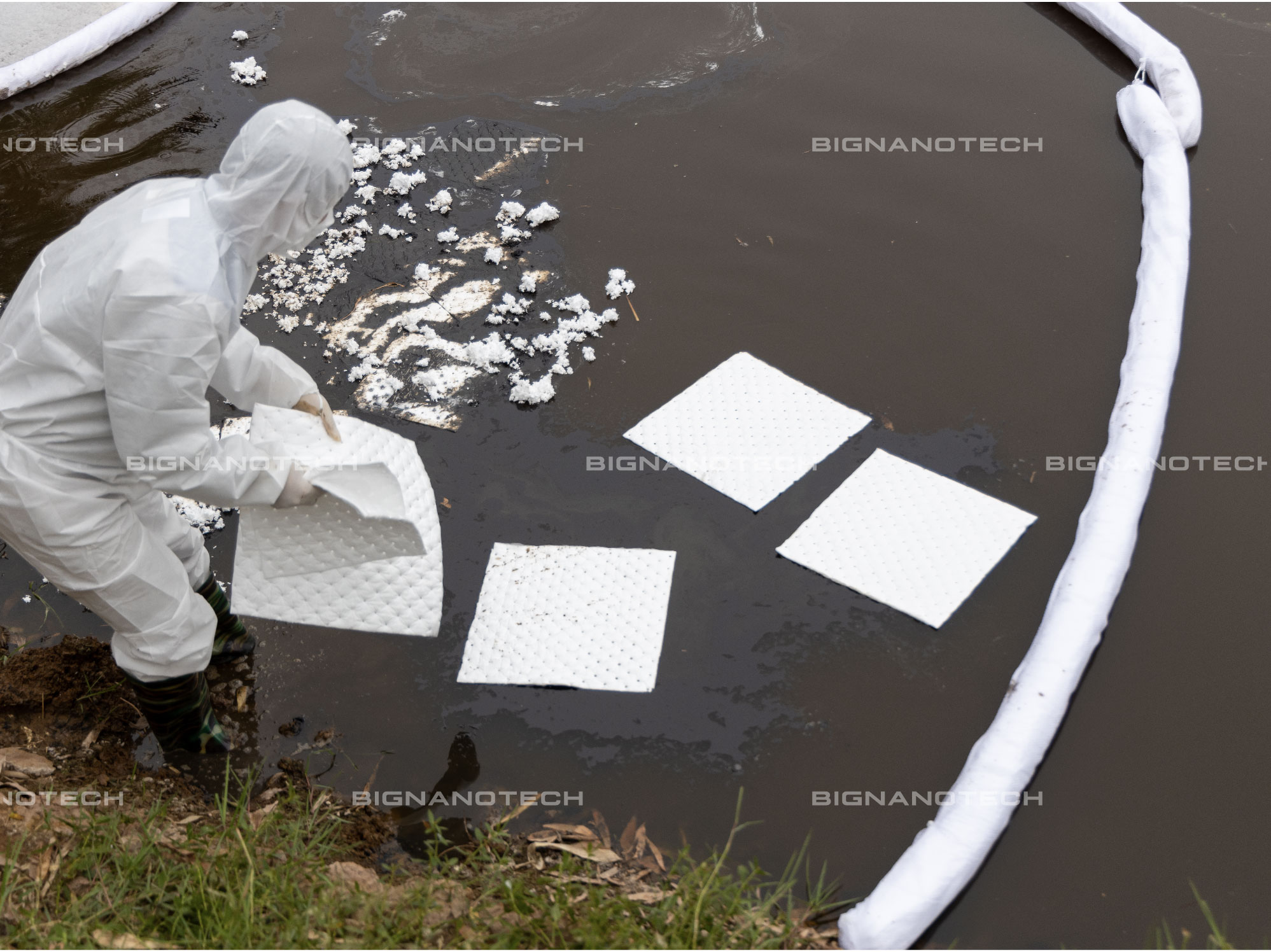

However, addressing the issue of oil pollution requires collective action on a global scale. Every individual, community, and business must prioritize environmental protection, adopt sustainable measures, and support responsible resource management. An effective measure in responding to and handling oil spill incidents is for offshore operating businesses and management organizations to have meticulous contingency plans in place and prepositioned resources to be prepared for any eventualities, thereby swiftly controlling and minimizing damages when incidents occur.

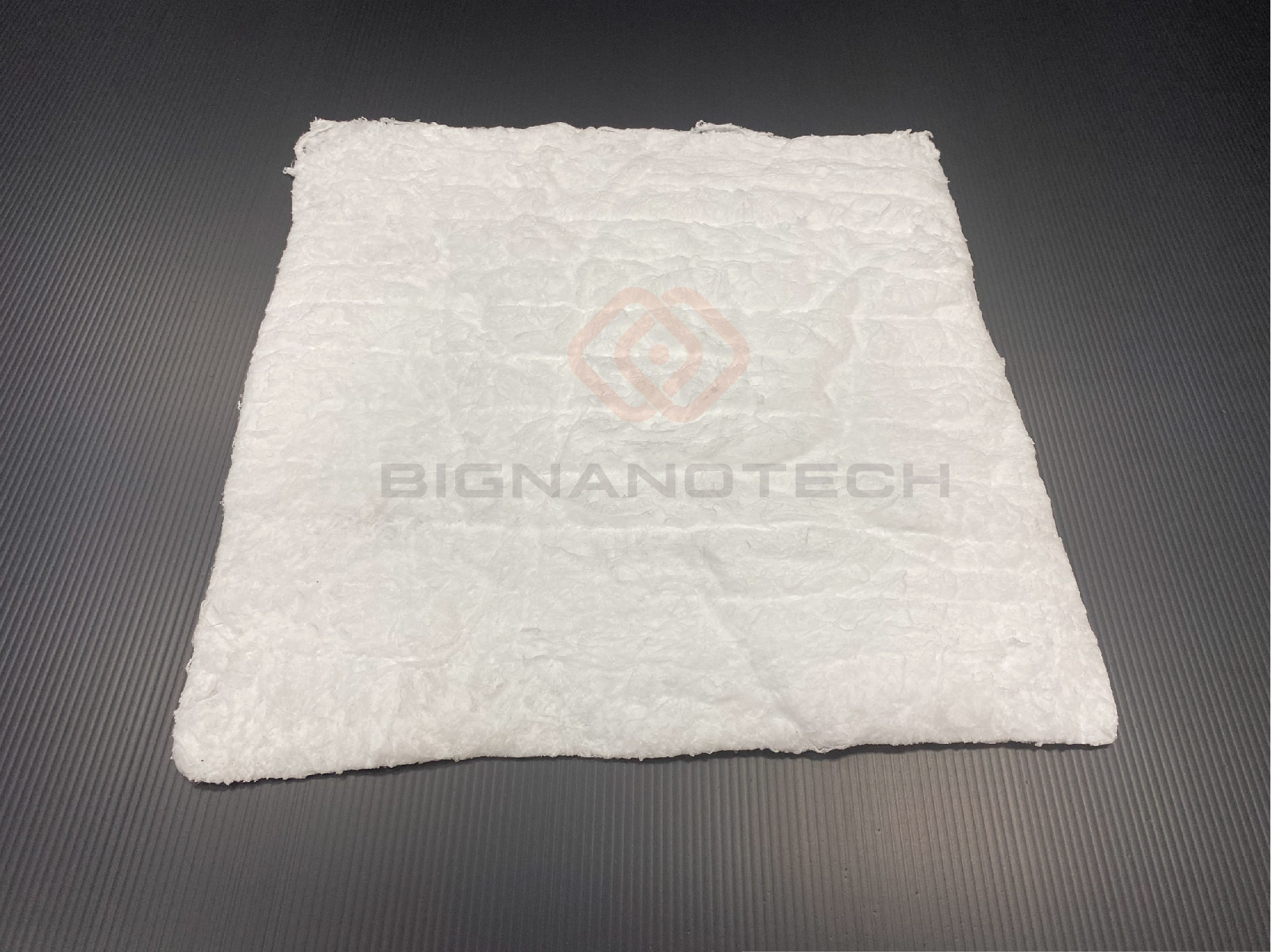

Products serving in responding to and handling offshore oil spill incidents, industrial oil spill cleanup include: Oil absorbent pads, oil absorbent booms, oil absorbent pillows, oil filter fabric, oil absorbent powder, biological oil-degrading powder…

As the world grapples with an escalating crisis of oil pollution, we can contribute to preserving the health and life of the oceans through collective efforts and commitments from businesses. Together, we must mitigate negative impacts and safeguard the future of our oceans.

For consultancy on industrial hygiene solutions and incident response, please contact:

BIGNANOTECH Company

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com