Imagine you’re overseeing a bustling industrial plant when an oil or chemical spill strikes—slippery floors, safety risks, and costly downtime loom large. According to the Ministry of Agriculture and Environment (post-merger on March 1, 2025, under Decree 35/2025/NĐ-CP), Vietnam faces hundreds of spill incidents yearly, causing environmental harm and financial losses worth billions of VND. These disruptions are a nightmare for factories, warehouses, and gas stations alike.

But what if there’s a game-changer that transforms chaos into control in mere minutes? Meet N- Powder NS10 Sorbents Oil Absorbent Powder from Bignanotech – the innovative solution that’s revolutionizing spill response across industries!

N-Sorbents Oil Absorbent Powder by Bignanotech effectively cleans oil and chemical spills on industrial floors

Let’s dive into why N- Powder Sorbents NS10 is more than just an absorbent – it’s a smart, eco-friendly tool that saves time, money, and the environment. From its standout features to real-world applications, this product is set to impress!

Standout Features of N- Powder Sorbents NS10 Oil Absorbent Powder: Nano-Tech Innovation

N- Powder Sorbents NS10 Oil Absorbent Powder, crafted by Bignanotech – Vietnam’s leading nano-material innovator – is made from 100% natural Cellulose, ensuring safety for humans, animals, and the ecosystem. Leveraging advanced nano-technology, this powder excels at absorbing a wide range of liquids – oils, chemicals, solvents, acids, bases, and bio-fluids – while leaving hard surfaces spotlessly dry with no residue.

Here are the impressive specs that make N- Powder Sorbents a standout:

- Product Code: NS10 – easy to order and track.

- Origin: Vietnam (Bignanotech brand), supporting local production with competitive pricing.

- Material: 100% Cellulose – fully biodegradable within 30 days, free from harmful chemicals, aligning with ISO 14001 environmental standards.

- Color: Natural brown – easy to spot and monitor during use.

- Package Size: 52cm x 36cm x 12cm – compact for easy storage in any facility.

- Absorption Capacity: 4 liters/1kg – outperforms standard products, tackling large spills with minimal powder.

- Packaging: 10kg/bag – ideal for medium-scale incidents.

- High Absorption: Absorbs liquids 10 times more than competitors, eliminating the need for secondary cleaners.

- Non-Toxic: Safe for the environment, humans, and animals – no skin or respiratory irritation.

10kg packaging of N-Sorbents Oil Absorbent Powder by Bignanotech

The nano-tech in N- Powder Sorbents NS10 enables instant absorption without hazardous reactions, turning wet spills into dry, sweepable mixtures. Unlike traditional absorbents that leave residue or odors, this powder ensures a clean, safe workspace, reducing slip-and-fall risks and fire hazards. Certified eco-friendly and safe, it’s a must-have for high-risk environments.

Real Benefits of N- Powder Sorbents for Your Business

N- Powder Sorbents deliver tangible economic and environmental perks. For industrial businesses like food processing plants, mechanic workshops, or gas stations, it cuts cleanup time by 50%.

Simply sprinkle the powder on the spill, wait 5-10 minutes, and sweep it away – no water or extra chemicals needed. This minimizes production downtime, saves labor costs, and reduces operating expenses by up to 30%. With a 10kg bag handling up to 40 liters of liquid, it’s perfect for daily minor spills.

Environmental agencies and cleaning crews love its eco-friendliness. With 100% biodegradability, N-Powder Sorbents cuts solid waste by 70%, complying with Ministry of Agriculture and Environment regulations and avoiding fines up to hundreds of millions of VND during inspections. Non-toxic and free from secondary pollution, it ensures worker safety and supports sustainable goals, boosting your brand’s green credentials.

Cost-effective and versatile, N- Powder Sorbents is a long-term investment, especially for small businesses with tight budgets, offering high performance at a fraction of imported product prices.

How to Use N-Powder Sorbents: Simple and Versatile

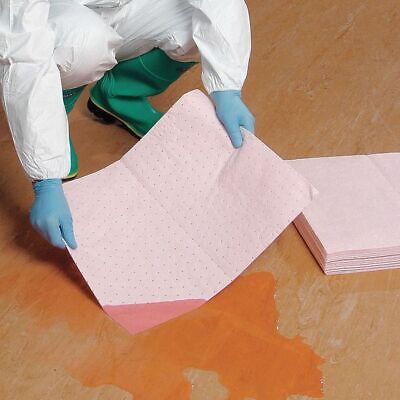

Using N-Powder Sorbents is a breeze, perfect for both new workers and emergency teams. Here’s a step-by-step guide based on practical use:

- Prepare: Identify the spill type (oil, chemical, solvent) and affected area. Open the bag and grab a broom or shovel. Avoid use with hazardous substances like hydrofluoric acid or mercury.

- Apply: Spread the powder evenly at a 1kg-to-4-liter ratio. Let it sit for 5-10 minutes to fully absorb, turning the wet mess into a dry mix.

- Collect: Sweep the absorbed mixture into a bag or container. The surface will be dry and clean, minimizing slip hazards.

- Post-Use: Dispose of used powder via burial or natural decomposition (100% biodegradable). Avoid dumping into drains to prevent water pollution. Store dry powder in a cool, ventilated area for reuse.

Safety Note: Wear gloves and safety goggles, follow fire safety protocols for flammable liquids, and consult Bignanotech for uncertain cases.

Practical Benefits for Businesses and Production Facilities

For industrial businesses, Bignanotech’s cleaning powder offers numerous tangible benefits. The product cuts cleaning time by 50% compared to traditional methods, thanks to its ability to break down oil and grease bonds without aggressive scrubbing, protecting equipment from wear and tear. Additionally, with processing costs 30% lower than conventional chemical cleaners, companies can optimize their operational budgets effectively.

Cleaning facilities and environmental organizations also highly value the product’s eco-friendliness. Its rapid biodegradability ensures compliance with regulations from the Ministry of Agriculture and Environment, reducing the risk of fines up to hundreds of millions of VND during surprise inspections. Moreover, the powder leaves no residue, ensuring worker safety and maintaining production quality.

Real-World Applications and Support from Bignanotech

At a seafood processing plant in Ca Mau in July 2025, Bignanotech’s cleaning powder successfully removed oil and grease from the production floor in just 15 minutes, improving working conditions and preventing food safety violations. Bignanotech goes beyond providing products by offering detailed usage guides and free consultations, helping businesses streamline their cleaning processes for maximum efficiency.

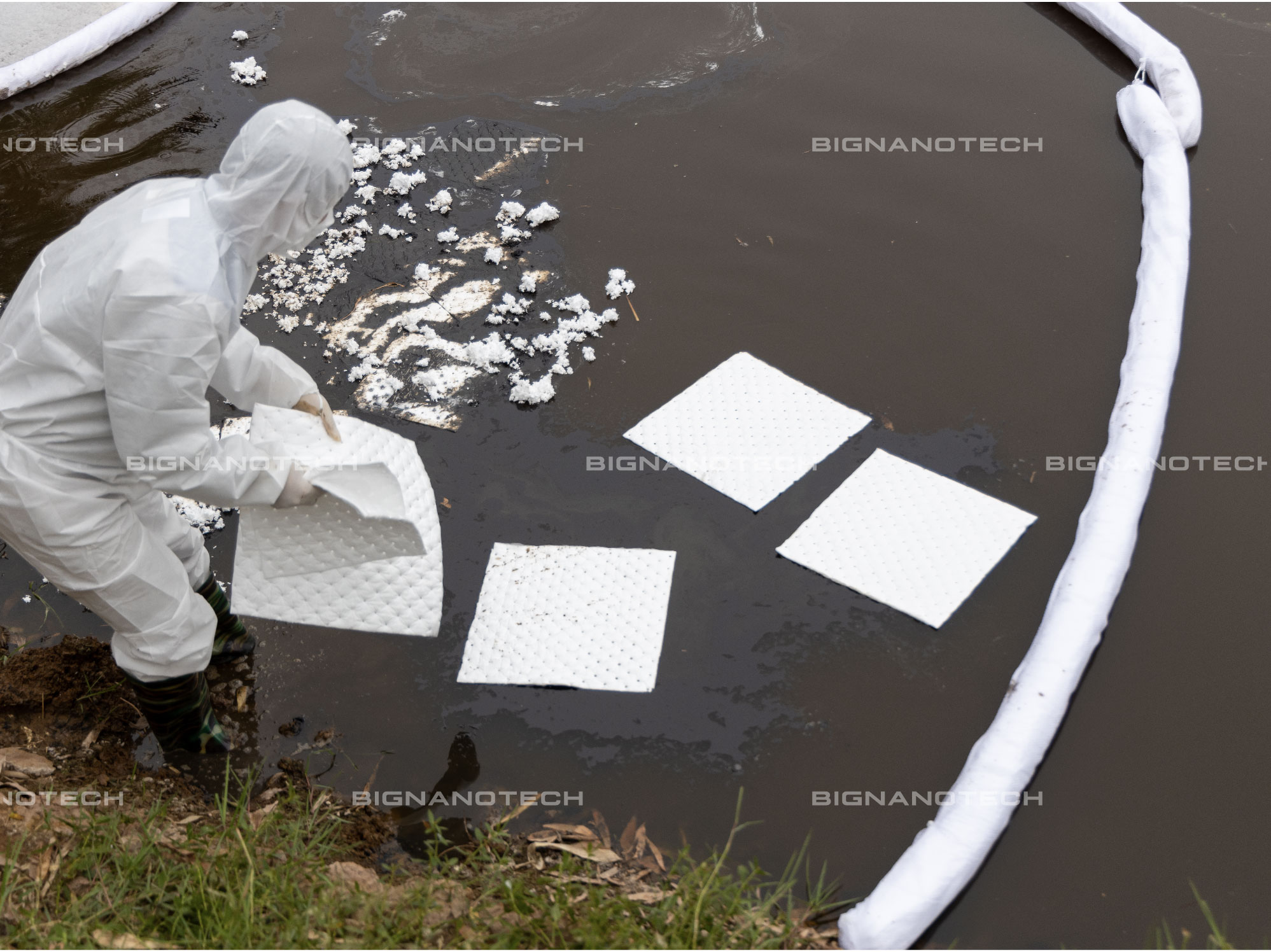

N-Sorbents Oil Absorbent Powder for oil spill cleanup in factories

How to Get Started?

If you’re a factory manager, production facility owner, or environmental officer, integrating Bignanotech’s cleaning powder into your daily routine is a smart move. The Bignanotech team is ready to assess your needs and recommend tailored solutions. Visit bignanotech.com to learn more or contact us today:

- Hotline: (+84) 879 808080

- Email: sales@bignanotech.com

With Bignanotech’s cleaning powder, you not only enhance cleaning efficiency but also contribute to sustainable environmental protection. Have you tried this solution yet? Share your experiences or questions in the comments below to discuss together!