Chemical spills can happen at any time in laboratories, chemical storage areas, around battery packs and dipping tanks, and in chemical processing plants, causing significant harm to people and the environment. However, addressing and cleaning up incidents involving hazardous chemicals is not easy due to their toxic and dangerous nature. BIGNANOTECH offers a safe solution to tackle this problem.

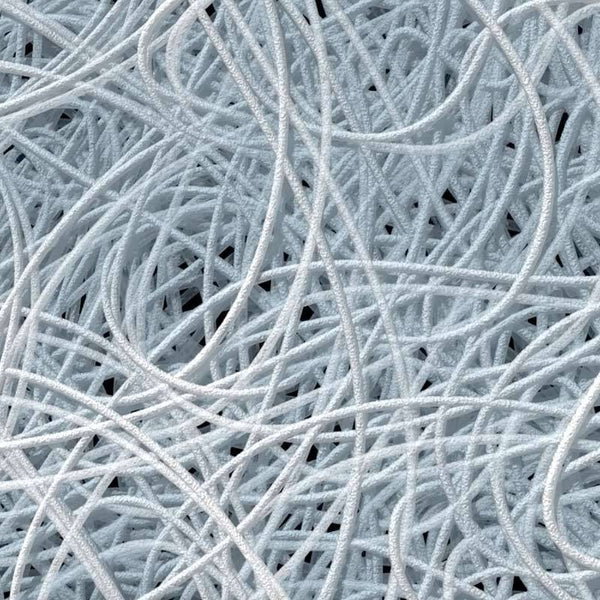

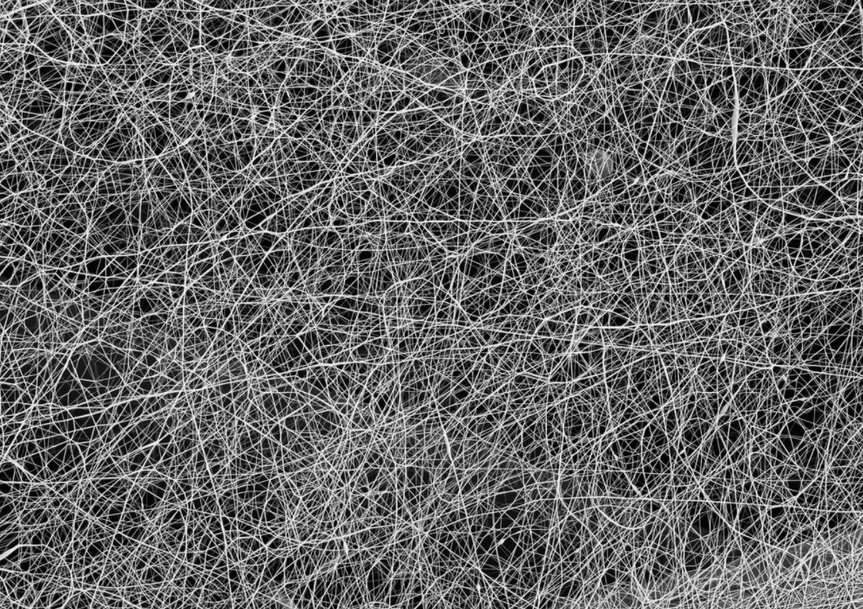

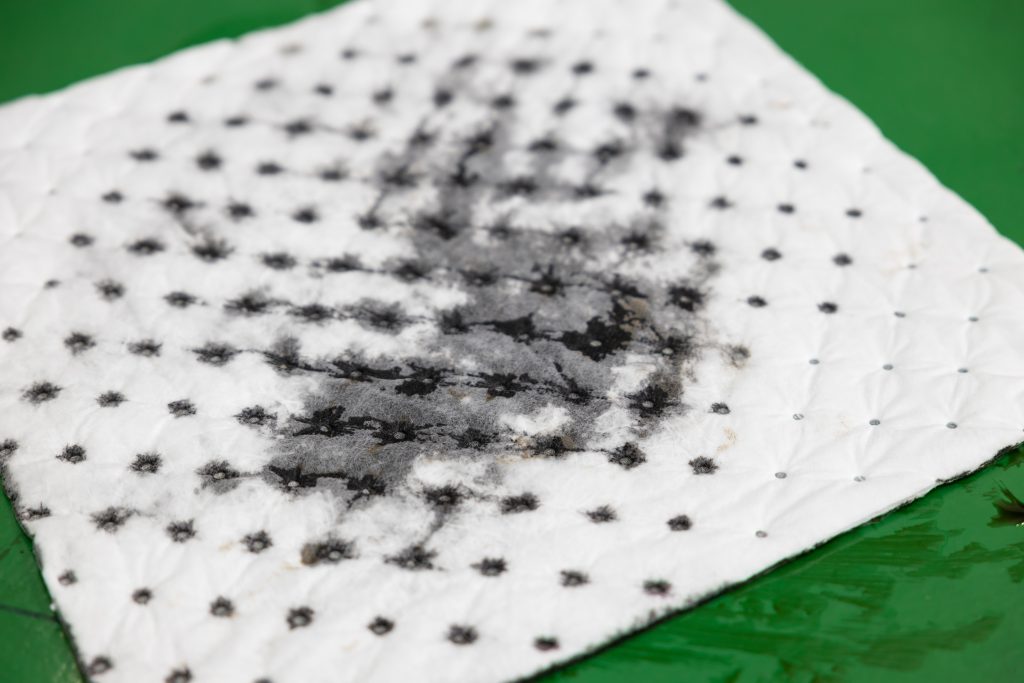

Common products used for cleaning and handling chemical spills include chemical absorbent pads, chemical absorbent booms, chemical absorbent pillows, cleaning powders, and quick response kits. These products are optimal for absorbing and collecting various acids, bases, corrosive substances, chemicals, and unidentified liquids, even those with high concentrations like 98% sulfuric acid and 30% sodium hydroxide. These products can clean up large spills or continuous leaks of liquids to minimize damage when a chemical spill occurs.

Using BIGNANOTECH materials and products, businesses/individuals can quickly and effectively respond to chemical spills at factories, plants, fuel stations, for large transport vehicles, and all areas with a risk of fuel, oil, chemical, and other industrial fluid spills.

When responding to a chemical spill or conducting regular cleaning in areas with chemicals, you can follow these safe handling steps:

Step 1: Use appropriate safety gear to respond to chemical spills (protective suits, gloves, goggles, etc.).

Step 2: Block the source of the chemical spill. At the same time, use chemical absorbent booms to prevent chemicals from spreading to surrounding areas.

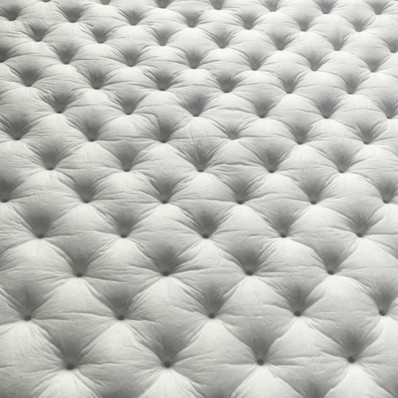

Step 3: Place chemical absorbent pads and chemical absorbent pillows over the entire surface of the spill to absorb and collect all the liquid.

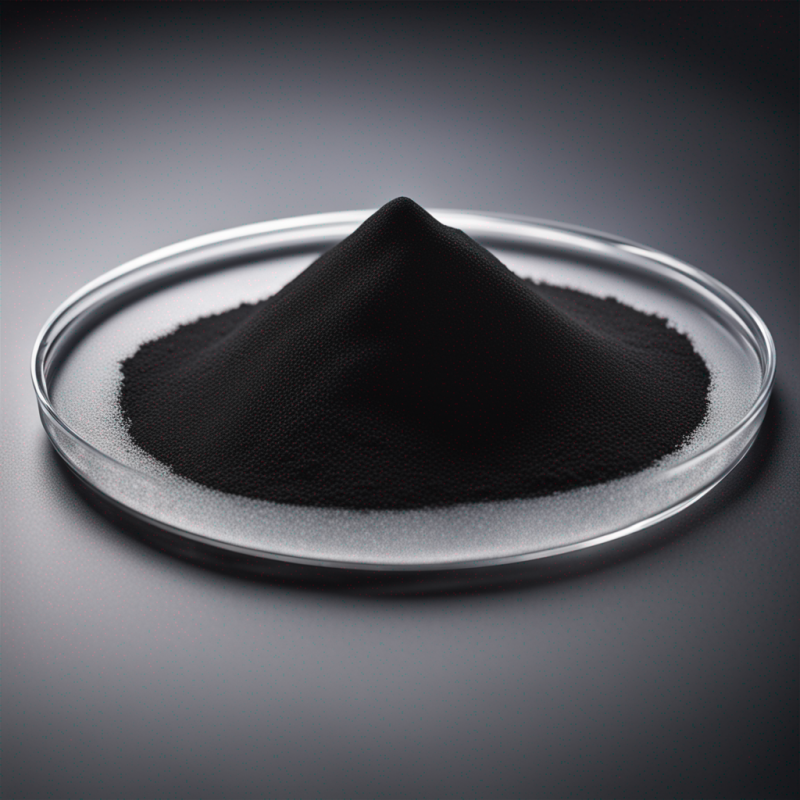

Step 4: Use cleaning powder on the spill area to absorb any remaining liquids on the surface. Then use a broom or stiff brush to scrub several times to ensure the surface is completely dry.

Step 5: After handling the incident, collect and reuse the equipment and tools used. Store the chemical-soaked products in a designated hazardous waste storage area, away from heat/flames, water reservoirs, and do not dispose of them in the environment to prevent cross-contamination.

Chemical absorbent products are commonly used in laboratories, chemical storage areas, around battery packs and dipping tanks, in processing plants, boiler rooms, R&D rooms, chemical warehouses, industrial zones, and industries with a risk of hazardous chemical leaks.

BIGNANOTECH is a reputable company in Vietnam specializing in manufacturing and distributing specialized products for environmental incident response and handling related to oil and industrial chemicals. With many outstanding features and more accessible prices compared to imported products, BIGNANOTECH products have been used in response and incident handling for many major units in Vietnam and are also present in international markets.

For product consultation, please contact:

BIGNANOTECH Company

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com