Corporate gifting is an essential aspect of modern business culture. A well-thought-out gift can strengthen relationships, leave lasting impressions, and even help your brand stand out. However, choosing the perfect creative gift for business requires careful thought and planning. It’s not just about giving something—it’s about giving meaningfully, showing appreciation, and building a bridge between your business and its stakeholders.

In this blog, we’ll explore the occasions for corporate gifts, why they matter, and the top 10 creative gift ideas to inspire your next gifting strategy.

1. When Are Corporate Gifts Used?

Corporate gifts are versatile tools that can enhance relationships and serve as thoughtful gestures on various occasions:

Meeting Partners and Customers

Whether it’s a first meeting or an ongoing partnership, gifts demonstrate hospitality and goodwill. They are an effective way to show appreciation for the time and effort that partners and customers invest in your business.

Corporate Anniversaries or Events

When celebrating milestones such as company anniversaries, product launches, or team achievements, giving gifts ensures that attendees remember the occasion fondly. A meaningful souvenir can act as a lasting reminder of your business’s successes and milestones.

Partner and Customer Holidays

Holidays and anniversaries of partners or customers are prime opportunities to send thoughtful gifts. These gestures show your sincerity and effort to maintain a warm, professional relationship.

2. Why Put Effort Into Selecting Corporate Gifts?

Gifting is more than a formality—it’s a chance to make a lasting impression and showcase your business’s personality.

Creating a Positive Impression

A carefully chosen gift conveys attention to detail and thoughtfulness. It tells recipients that your business values the relationship and invests in fostering it.

Reflecting Your Business Personality

Your choice of gift reflects your company’s values and culture. By selecting unique, meaningful gifts, you create a professional and memorable image for your business.

3. Top 10 Creative Gift Products for Businesses

Here are ten thoughtful and creative gift ideas that can make your business stand out.

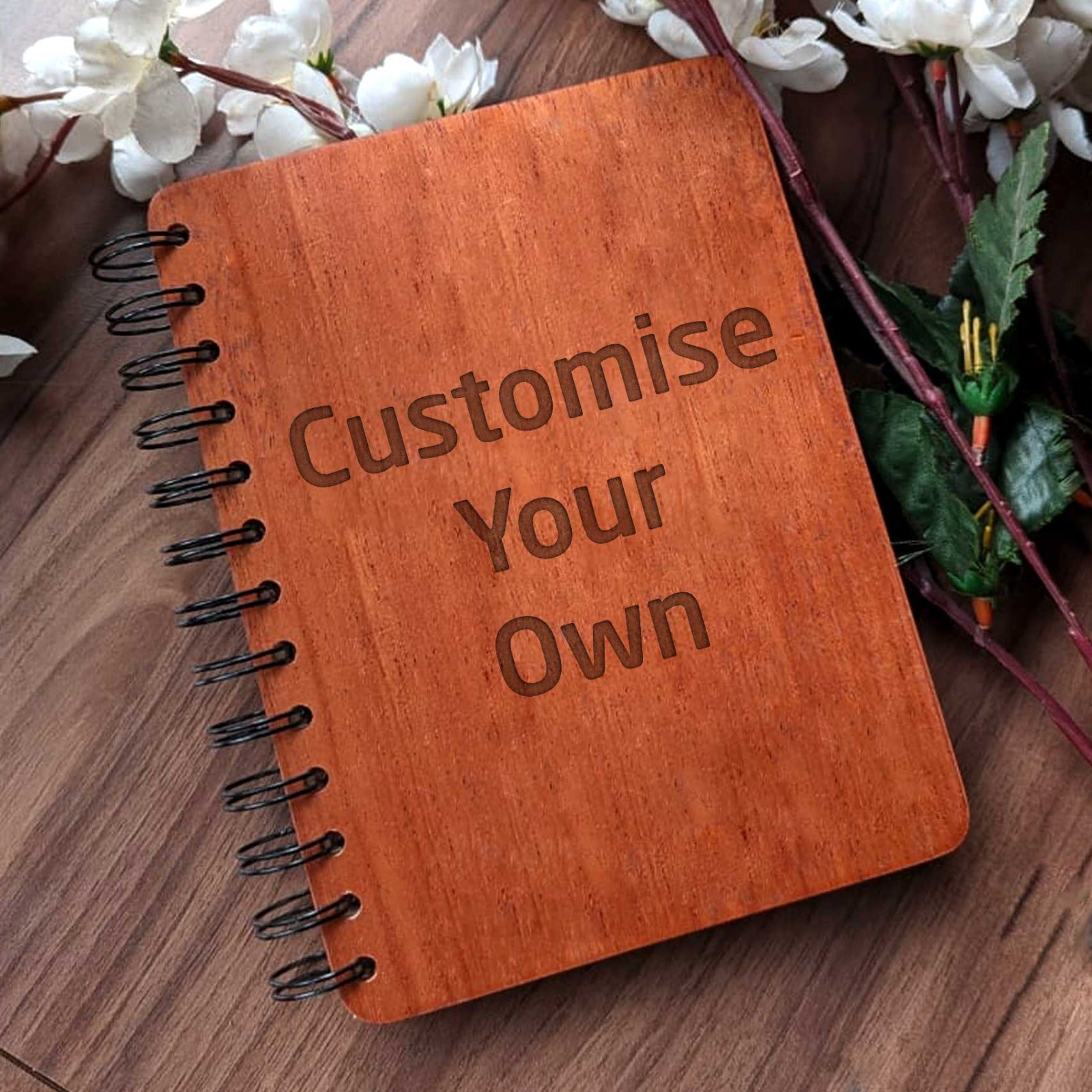

3.1 Customized Notebooks

Notebooks are classic yet highly functional gifts for professionals. Adding a personal touch—such as the recipient’s name, your brand logo, or an inspirational quote—transforms an ordinary notebook into a memorable keepsake.

Why Choose Customized Notebooks?

- They’re practical for everyday use, especially for professionals who value organization.

- Personalization adds a unique touch that enhances sentimental value.

- High-quality notebooks leave a positive impression of your brand’s attention to detail.

Customized notebooks are versatile and can be sourced from reliable stationery providers or specialized printing companies.

3.2 Eco-Friendly N-Leaf Souvenirs

N-Leaf souvenirs are a standout option for businesses committed to sustainability. These items, crafted from natural areca leaves, can be laser-engraved with logos, slogans, or even iconic images of local attractions.

Why Choose N-Leaf Souvenirs?

- Sustainability: They showcase your commitment to eco-friendly practices, resonating with modern values.

- Customization: Laser printing allows unique designs that make your brand memorable.

- High-Quality Materials: Made from durable, natural materials that reflect thoughtfulness and care.

N-Leaf souvenirs are available directly from BIGNANOTECH, a trusted provider of organic and eco-friendly products.

3.3 Smart Desk Accessories

In a tech-driven world, smart desk accessories like wireless chargers, portable speakers, or USB hubs are always appreciated. These tools are functional and add convenience to everyday professional life.

Why Choose Smart Desk Accessories?

- They’re universally useful, appealing to recipients across industries.

- Modern designs align with current workplace trends.

- They reinforce your brand’s innovative and forward-thinking image.

Several tech companies offer customization options, allowing you to add your branding for an extra personal touch.

3.4 Personalized Calendars

Calendars are a timeless gift that ensures year-round visibility for your brand. Personalize them with unique artwork, motivational quotes, or important dates related to your business.

Why Choose Personalized Calendars?

- They serve a practical purpose, used daily by recipients.

- Custom designs reflect creativity and keep your brand top-of-mind.

- They provide an excellent opportunity to tell your company’s story.

Work with local printing shops or online services to create high-quality calendars tailored to your audience.

3.5 Gourmet Gift Hampers

Gourmet hampers filled with premium snacks, chocolates, or artisanal foods are delightful and versatile gifts. You can even tailor hampers to reflect the recipient’s tastes or cultural preferences.

Why Choose Gourmet Gift Hampers?

- They’re luxurious yet approachable, suitable for any occasion.

- Customizable contents allow for thoughtful and personal touches.

- They convey a sense of care and generosity.

Choose hampers from specialty stores or curate your own to create a truly bespoke experience.

3.6 Sustainable Drinkware

Reusable drinkware like water bottles, coffee mugs, or tumblers made from eco-friendly materials like bamboo or stainless steel is both practical and sustainable.

Why Choose Sustainable Drinkware?

- It promotes environmentally responsible practices, aligning your brand with sustainability values.

- Stylish designs enhance usability and appeal.

- Custom printing ensures branding visibility.

Eco-conscious suppliers offer a variety of drinkware styles, making it easy to find options that suit your brand.

3.7 Digital Gift Cards

Digital gift cards are the ultimate flexible gift. Recipients can choose items they truly want or need, ensuring satisfaction.

Why Choose Digital Gift Cards?

- They’re versatile and suitable for recipients across different demographics.

- They eliminate logistical challenges, making them ideal for long-distance partners or clients.

- They reflect a modern, tech-savvy image.

Opt for gift cards from reputable retailers or industry-specific vendors for added relevance.

3.8 Branded Apparel

Branded clothing like T-shirts, caps, or scarves combines functionality with subtle marketing. Ensure designs are trendy and versatile so recipients enjoy wearing them.

Why Choose Branded Apparel?

- It’s a walking advertisement for your brand.

- High-quality materials and stylish designs enhance the perceived value of your brand.

- Apparel is practical and appreciated by recipients.

Work with apparel designers who can incorporate your branding seamlessly into fashionable designs.

3.9 Customized Board Games or Puzzles

These gifts add an element of fun and engagement, perfect for team-building activities or family-friendly occasions.

Why Choose Board Games or Puzzles?

- They encourage interaction and create memorable experiences.

- Customization with your branding or business themes makes them unique.

- They suit recipients of all ages and professions.

Specialized game designers can help you create bespoke games that resonate with your brand identity.

3.10 Office Plants

Small plants like succulents or lucky bamboo are delightful gifts that bring life to office spaces.

Why Choose Office Plants?

- They improve indoor air quality and add aesthetic appeal.

- Personalization with branded pots or planters creates a memorable gift.

- They symbolize growth and prosperity, aligning with business values.

Partner with local florists or eco-friendly plant suppliers to source these natural gifts.

4. Summary

Corporate gifts are more than tokens of appreciation—they’re tools to build relationships, enhance your brand image, and leave lasting impressions. By selecting creative gifts for businesses, such as eco-friendly N-Leaf souvenirs or personalized calendars, you showcase thoughtfulness and align your brand with meaningful values.

Whether you’re celebrating milestones, thanking partners, or building customer loyalty, the right gift speaks volumes about your business’s personality. Let these creative gift ideas inspire your next corporate gifting campaign, ensuring every gesture strengthens your professional connections.