Do you think managing oil spills is an impossible, costly, and non-compliant task? Think again!

Oil absorbent cotton from Bignanotech is the ultimate solution, absorbing oil spills up to 50 times its own weight, remaining completely non-water-absorbent, and eliminating all residues, fully compliant with Decree 12/2021/QĐ-TTg and Decree 24/2025/QĐ-TTg on oil spill response in Vietnam. This cutting-edge nanotechnology has been proven effective through hundreds of real-world applications in rivers, factories, and aquaculture ponds. Don’t let oil pollution destroy your environment and business! Read on to understand why you must purchase oil absorbent cotton today and take immediate action!

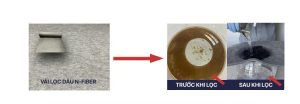

Oil absorbent cotton by Bignanotech

Outstanding Features of Oil Absorbent Cotton: Compliant with Oil Spill Response Standards

Do you doubt that oil absorbent products are just low-quality, inexpensive goods? Face the truth: Oil absorbent cotton is engineered from premium nano-fibers, meeting the safety standards for oil absorbent materials as outlined in oil spill response regulations. It selectively “devours” oil while repelling water 100%, effectively tackling dry oil, wet oil, surface slicks, or submerged oil—all within minutes.

- Superior Selective Absorption: Exclusively absorbs oil, not water, adhering to oil recovery requirements. One kilogram of oil absorbent cotton can absorb up to 50 liters of oil spill, outperforming conventional cotton by 10 times.

- Absolutely Environmentally Safe: Free from harmful chemicals, eco-friendly, and aligned with environmental protection standards under oil spill response regulations. Certified safe for fish, shrimp, and aquatic plants.

- User-Friendly and Cost-Effective: Simply spread over the oil spill, wait 5-10 minutes for complete absorption, and collect with a net—a straightforward process meeting emergency response timelines.

- Versatile Applications: Perfect for managing river oil spills, industrial oil waste, diesel leaks from traffic accidents, or machinery oil in factories, fully supporting oil spill contingency plans.

Oil absorbent cotton with nanotechnology for effective oil spill management

With Bignanotech’s nanotechnology, oil absorbent cotton delivers unmatched efficiency while ensuring regulatory compliance, helping you avoid fines and reduce environmental cleanup costs annually.

Detailed Technical Specifications: Choose the Right Oil Absorbent Cotton for Your Needs

We provide transparent data to ensure you select the perfect product, meeting oil spill response material requirements:

|

Product Code |

Packaging |

Maximum Absorption Capacity |

Primary Application |

| N-FIBER PULP2 | 2kg/box |

Up to 100 liters of oil |

Small-scale spills, aquaculture |

| N-FIBER PULP5 | 5kg/box |

Up to 250 liters of oil |

Industrial spills, large rivers |

Each package is moisture-resistant, easy to store, and delivered nationwide within 24-48 hours. Competitive pricing suits all scales, from households to large enterprises, ensuring readiness for emergencies as per legal standards.

Real-World Applications of Oil Absorbent Cotton: Compliant with Oil Spill Response Regulations

Imagine this: An oil spill from a cargo ship on the Mekong River causes mass fish deaths, leaving your business facing fines of billions of VND for violating oil spill response regulations. Will you wait for slow environmental authorities or act immediately? Oil absorbent cotton from Bignanotech has proven its effectiveness, offering rapid solutions and strict adherence to oil spill response protocols:

- Emergency River Spill Response: In Cần Thơ, the product neutralized oil spills from vessels in just 15 minutes, meeting the maximum 1-hour response time required by oil spill response regulations. This not only saved the environment but also prevented hefty penalties from authorities.

- Industrial Environmental Protection: In Bình Dương, oil absorbent cotton efficiently collected machinery oil waste, preventing groundwater contamination and avoiding fines up to 500 million VND as mandated by oil spill response regulations. It ensures thorough cleanup, aligning with local contingency plan assessments.

- Diesel Spill Mitigation: From truck oil leaks to agricultural machinery spills, the product absorbs oil completely, leaving no odor or residue, fulfilling the thorough cleanup and timely reporting requirements of oil spill response regulations. This practical solution has been widely adopted, helping businesses avoid legal liabilities.

- Aquaculture Protection: It prevents oil spills from pumps, safeguarding shrimp and fish from mass deaths, complying with water and ecosystem protection standards under oil spill response regulations. Many farmers in the Mekong Delta have successfully used it, reducing economic losses by up to 50% compared to traditional methods.

These applications are not just theoretical—they are real-world evidence from actual incidents, proving oil absorbent cotton is an essential tool for businesses and individuals to comply with regulations, protect the environment, and save costs. Don’t wait for a spill to happen—equip yourself today to be fully prepared!

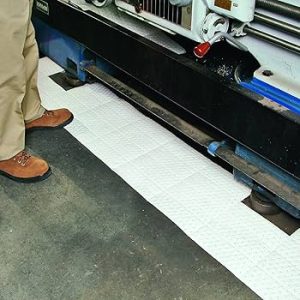

Workers using oil absorbent cotton to manage river oil spill

Usage Guide for Oil Absorbent Cotton: Detailed, Practical, and Legally Compliant

Are you worried that oil absorbent products are difficult to use or fail to meet standards? Not at all! The detailed 5-step process below ensures compliance with oil spill response regulations, delivering maximum efficiency and absolute safety:

- Assess the Scale of the Oil Spill: Determine the area and thickness of the spill (1kg of oil absorbent cotton handles 50m² of thin oil, doubling for thicker oil), adhering to initial survey requirements.

- Prepare Equipment: Use gloves, protective gear, and nets according to occupational safety standards, ensuring risk prevention protocols are followed.

- Spread Evenly: Distribute oil absorbent cotton uniformly across the entire oil spill surface, ensuring full coverage, in line with emergency response guidelines.

- Wait for Complete Absorption: Allow 5-15 minutes depending on oil thickness, observing the cotton change from white to dark brown as oil is fully absorbed, meeting stipulated processing times.

- Collect and Dispose: Use nets or tongs to gather the oil-saturated cotton, incinerate or recycle per local environmental regulations, preventing re-contamination.

Expert Tip: For large spills, apply in a spiral pattern from the outside in to optimize performance, and report results to authorities as required. The product stores well at 0-40°C, is non-flammable, and suits Vietnam’s climate conditions.

Why Choose Oil Absorbent Cotton from Bignanotech Today?

Oil spills don’t wait for indecision! Oil absorbent cotton is Vietnam’s top solution, compliant with Decree 12/2021/QĐ-TTg and Decree 24/2025/QĐ-TTg, saving hundreds of businesses from losses and penalties. With competitive pricing, 24-48 hour delivery, and 24/7 support, there’s no excuse to delay.

Strong Call to Action: Order oil absorbent cotton today to enjoy discount on your first order! Call hotline (+84) 879 808080 or email sales@bignanotech.com. Visit bignanotech.comto buy online now!

Learn More: Oil Spill Response Guide per Decree 12/2021 & 24/2025

Don’t let oil spills breach regulations—control them with oil absorbent cotton from Bignanotech today!