In recent years, the global trend has been shifting chemical manufacturing plants to developing countries, giving Vietnam significant advantages in attracting investment. Moreover, the chemical industry has been identified by the Party and the State as a foundational and priority sector for development.

How is the Vietnam’s chemical industry developing?

According to the Department of Chemicals under the Ministry of Industry and Trade, large industries that use many chemical products as raw materials, such as electronics, steel, textiles, footwear, and automobiles, are experiencing good growth. These sectors are part of the priority industries for development. Statistical data shows that the annual production of Vietnam’s chemical industry accounts for about 10-11% of the total GDP of the industrial sector. The workforce makes up nearly 10% and has a labor productivity rate 1.36 times higher than the national industrial average, thanks to a high level of automation. Additionally, Vietnam’s long coastline and deep-water ports provide the necessary conditions for developing chemical industrial centers and logistics hubs.

Petrochemical and Basic Chemical Sub-Sectors

Petrochemicals and basic chemicals serve as the primary raw materials for many production fields. The development of these sectors boosts other industries, such as fertilizers, paper, plastics, glass, ore processing, metallurgy, petrochemicals, leather tanning, textile dyeing, batteries, soaps, detergents, water treatment chemicals, food, pharmaceuticals, pesticides, pigments, and concrete additives.

Future Projections for the Vietnam’s Chemical Industry

Based on these practical foundations, the Vietnamese government has set an overall goal for 2030 to build a relatively complete chemical industry, including the production of both industrial and consumer goods, serving various sectors. The goal by 2040 is for Vietnam’s chemical industry to develop with most sub-sectors using advanced technologies and products meeting international standards, deeply integrated into the global value chain.

Associated Risks

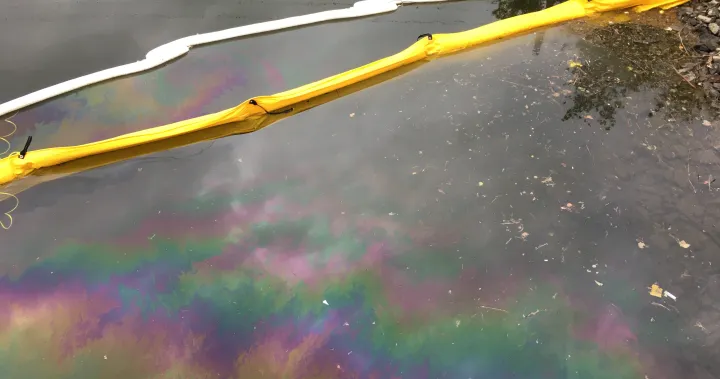

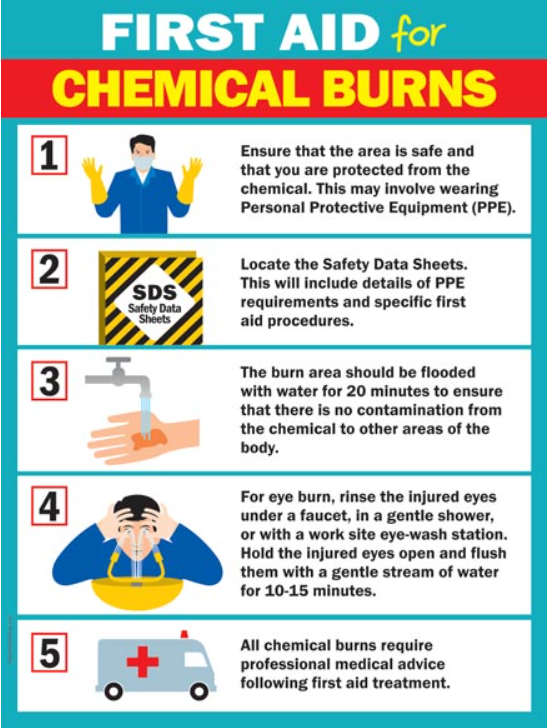

Alongside the continuous development of the chemical market and industry is the increasing risk of chemical incidents. The frequency of industrial chemical spills and leaks is rising, posing potential dangers to our environment and health. Every year, hundreds of chemical-related accidents occur globally with varying degrees of severity. For example, in the U.S. alone, there is an average of one chemical incident every two days, with over 340 chemical accidents recorded in 2022.

This situation is becoming more serious as climate change increases the frequency of natural disasters like storms and floods, raising the risk of chemical spills from industrial facilities that are inadequately prepared.

Chemical Spill Incidents in Vietnam

Currently, there is no detailed and comprehensive data on the number of industrial chemical spills or leaks in Vietnam. However, the country has made significant strides in managing and preventing chemical-related incidents, particularly through updating regulations on chemical control, environmental safety, and waste management. Several laws and decrees, such as the Fire Prevention Law and regulations on hazardous goods transport, have been revised to enhance response capabilities to chemical incidents.

Improving and updating the environmental and chemical legal framework in Vietnam also reflects the government’s great concern in reducing environmental risks, including chemical spills. The Ministry of Natural Resources and Environment, along with other regulatory bodies, has been involved in monitoring and reporting pollution and chemical-related incidents.

One measure includes requiring chemical storage, trading, or industrial production facilities to be equipped with necessary response tools to control and handle incidents as soon as they occur. Chemical spill response kits are currently the most popular choice. Businesses are encouraged to quickly update safety rules and prepare necessary incident response products to protect their workers and enterprises.

Contact BIG NANO TECHNOLOGY today for consultation and to secure the best chemical absorbent products.

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com