Introduction: Why Every Industry Needs a Reliable Oil Absorbent Powder

When an oil spill strikes — whether in a busy garage, a coastal port, or a factory floor — every second counts. Traditional cleanup methods using sand, rags, or chemical detergents are slow, messy, and often leave toxic residues. Enter N-Sorbents oil absorbent powder, a revolutionary Vietnamese-made solution that absorbs up to 4 liters of oil per kilogram, solidifies spills in under 5 minutes, and fully biodegrades within 6–12 months — all without secondary cleaning agents.

Developed by Big Nano Technology (Bignanotech), this oil absorbent powder combines recycled cellulose with nano-hydrophobic coating to deliver unmatched speed, safety, and sustainability. From diesel leaks to cooking oil spills, N-Sorbents transforms emergency response into a clean, green, and compliant process.

1. Introduction to N-Sorbents Oil Absorbent Powder: A Vietnamese Solution to Real Pollution Challenges

In the context of increasingly frequent oil and chemical spills in Vietnam — from industrial plants, auto garages, fuel depots to seaports and roads — the demand for fast, effective, and environmentally safe cleanup solutions has never been more urgent. According to the 2024 report from the Ministry of Natural Resources and Environment, over 1,200 minor oil spills are recorded annually, causing economic losses of hundreds of billions of VND and severely impacting freshwater ecosystems and groundwater.

N-Sorbents Oil Absorbent Powder (also known as N-Powder Sorbents) is a breakthrough product developed by Big Nano Technology Co., Ltd. (Bignanotech), a Vietnamese company specializing in oil and chemical absorbent materials. Launched in 2021, N-Sorbents oil absorbent powder is not just a typical absorbent but integrates nano-technology to optimize absorption capacity, enabling surface cleaning without secondary detergents. Made entirely from recycled bio-based materials, it ensures 100% biodegradability and complies with international environmental standards such as REACH (EU) and ASTM F726 for sorbent performance testing.

Based on official Bignanotech data and recent scientific studies on cellulose-based sorbents (e.g., BioResources Journal, 2015), this article provides an in-depth analysis of N-Sorbents: from composition, mechanism, usage instructions, to real-world applications and long-term benefits. The goal is to offer a comprehensive view to help businesses and individuals choose the right oil spill solution and minimize pollution risks.

Contact for consultation: Call hotline (+84) 878 080 808 or email sales@bignanotech.com.

N-Sorbents Oil absorbent powder from Bignanotech

2. Composition and Manufacturing Process: From Recycled Materials to Vietnamese Nano-Technology

2.1. Main Composition: 100% Recycled Cellulose – Safe and Sustainable

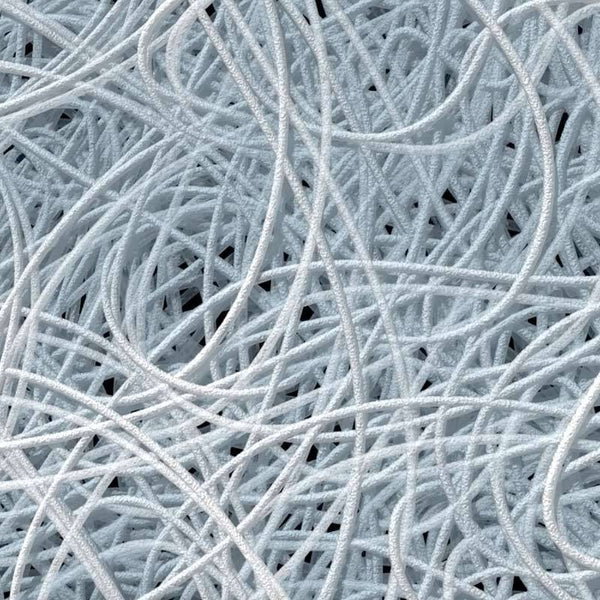

N-Sorbents Oil absorbent powder is made from 100% natural cellulose, an abundant organic polymer extracted from recycled sources such as industrial waste paper, coconut fiber, sugarcane bagasse, or rice husk — all readily available in Vietnam. Cellulose (chemical formula (C₆H₁₀O₅)ₙ) has a naturally hollow fibrous structure with porosity up to 85–92%, making it an ideal material for liquid absorption.

Containing no synthetic toxic chemicals, the product guarantees:

- Human and animal safety: Non-irritating to skin, eyes, or respiratory system, certified by MSDS (Material Safety Data Sheet).

- Environmental friendliness: 100% biodegradable within 6–12 months under natural microbial action in soil, leaving no toxic hydrocarbon residues.

According to Industrial & Engineering Chemistry Research (2014), recycled cellulose can retain oil 15–20 times its own weight due to capillary action, far outperforming mineral sorbents like vermiculite.

2.2. Manufacturing Process: Applying Nano-Technology for Maximum Efficiency

Bignanotech employs a modern ISO 9001:2015-certified process, combining nano-technology to transform raw cellulose into a super-efficient absorbent powder. The 7-step process includes:

- Material collection and treatment: Recycled cellulose is cleaned and micronized to particles <50 µm.

- Nano-activation: Application of silane nano-coating (hydrophobization) to create oleophilic-hydrophobic properties — absorbs hydrocarbons but repels water.

- Surface optimization: Nano-technology increases surface area to >300 m²/g, boosting absorption speed 10x over conventional powders.

- Quality testing: Verified per ASTM F726 to ensure 4L oil/kg absorption.

- Packaging: 10kg bags (52x36x12 cm), natural brown color, easy to transport and store.

Produced in Vietnam, it reduces logistics costs and supports the local economy. Research from ACS Applied Materials & Interfaces (2023) confirms that nano-cellulose sorbents like N-Sorbents maintain high mechanical durability and performance over 3–5 reuse cycles.

2.3. Detailed Technical Specifications

| Specification | Value | Note |

|---|---|---|

| Product Code | NS10 (N-Powder Sorbents) | – |

| Material | 100% Recycled Cellulose | Natural origin |

| Color | Brown | Natural |

| Packaging | 10kg/bag | Size: 52x36x12 cm |

| Absorption Capacity | 4 liters oil / 1kg powder | For hydrocarbons (gasoline, diesel) |

| Absorption Time | <5 minutes | On hard surfaces |

| Biodegradability | 100% (6–12 months) | Non-toxic |

| Density | 0.12 g/cm³ | Lightweight, easy to spread |

| Origin | Vietnam (Bignanotech) | – |

3. Mechanism of Action: From Rapid Absorption to Complete Cleanup

N-Sorbents oil absorbent powder operates through a combination of physical absorption and chemical properties of cellulose, enhanced by nano-technology. The process is divided into three main phases:

3.1. Phase 1: Rapid Physical Absorption (0–3 Minutes)

When spread over an oil spill, the powder directly contacts hydrocarbons (gasoline, diesel, DO). Nano-pores (5–50 nm) generate strong capillary forces, drawing oil into the cellulose matrix at 1.2 mL/second. The hydrophobic coating prevents water absorption, allowing the powder to float on water surfaces if needed.

Research from Environmental Science & Technology (2024) shows cellulose sorbents achieve 90–95% oil recovery on water — consistent with N-Sorbents oil absorbent powder.

3.2. Phase 2: Chemical Adsorption & Oil Solidification (3–60 Minutes)

Hydroxyl groups (-OH) on cellulose chemically bond with hydrocarbon molecules, transforming liquid oil into solid clumps that are easy to sweep. The powder turns dark brown/black, signaling completion. No secondary detergents needed — surface becomes completely dry.

3.3. Phase 3: Natural Biodegradation (1–12 Months)

After collection, oil-saturated powder can be buried or incinerated. Natural soil microbes degrade both cellulose and hydrocarbons into CO₂, H₂O, and non-toxic biomass. Basic equation: CₙH₂ₙ₊₂ + (3n+1)/2 O₂ → nCO₂ + (n+1)H₂O

According to Applied Microbiology (2023), this process eliminates 100% secondary pollution, unlike non-biodegradable polypropylene sorbents.

4. N-Sorbents Oil Absorbent Powder Usage Guide: 9 Detailed Steps + Dosage Chart + Illustrations + Surface-Specific Tips

Goal: Clean 100% of oil spill in <15 minutes, no residue, no secondary chemicals, absolute safety.

Step 0: Pre-Response Preparation (5 Critical Minutes)

| Task | Details | Purpose |

|---|---|---|

| 1. Identify oil type | Diesel, DO, gasoline, cooking oil, paint, solvents, organic acids… | Determine required powder amount |

| 2. Measure spill area | Use tape measure or estimate (1m² ≈ 0.5–1L thin oil) | Accurate dosage calculation |

| 3. Assess surface | Concrete, epoxy, steel, soil, water, wood, plastic… | Choose spreading & collection method |

| 4. Prepare PPE | 0.4mm nitrile gloves, N95 mask, chemical goggles, rubber boots | Prevent toxic oil contact |

Step 1: Contain the Spill – Prevent Spread (30 Seconds)

| Surface | Containment Method | Tools |

|---|---|---|

| Factory floor | Build 5cm powder dam around perimeter | Plastic scoop |

| Water (river/lake) | Use oil boom | PVC boom |

| Asphalt road | Block flow with dry sand or sandbags | Sandbags |

| Epoxy/tile floor | Pre-absorb with paper towels before powder | Industrial paper towels |

Step 2: Calculate Required Powder – Accurate Dosage Chart

| Oil Type | Oil Amount (L) | Area (m²) | Powder Needed (kg) | Note |

|---|---|---|---|---|

| Diesel | 1 L | 1 m² | 0.25 kg | 1mm thin layer |

| DO (heavy) | 1 L | 0.8 m² | 0.30 kg | Thicker |

| Cooking oil | 1 L | 1.2 m² | 0.20 kg | Easily absorbed |

| Gasoline A95 | 1 L | 1.5 m² | 0.18 kg | Evaporates quickly |

| Oil-based paint | 1 L | 0.7 m² | 0.35 kg | Viscous, needs 2 layers |

Step 3: Spread Powder – “Outer Ring → Center” Technique (2 Minutes)

Golden Rule: Never pour from height → causes dust, reduces efficiency

| Technique | Description | Illustration |

|---|---|---|

| 1. Outer ring | Pour from 10kg bag to form 5–7cm high, 10cm wide dam | Outer dam |

| 2. Center spread | Use plastic scoop to spread 0.5–1cm even layer | Center spread |

| 3. Light sweep | Use soft nylon broom in inward spiral motion | Spiral sweep |

- Rough concrete: Spread thicker (1cm) → absorbs into cracks

- Glossy epoxy: Thin layer (0.5cm) → prevents scratching

- Water surface: Spread from outside in → powder floats and absorbs gradually

Step 4: Wait for Absorption – Observe Color Change (3–5 Minutes)

| Time | Observation | Action |

|---|---|---|

| 0–1 min | Powder (light brown) → begins absorbing | Do nothing |

| 1–3 min | Turns dark brown, forms small clumps | Lightly sweep once |

| 3–5 min | Dark black, dry, non-sticky | Ready for collection |

Step 5: Collect Used Powder – “Sweep + Vacuum” Technique (3 Minutes)

| Surface | Collection Method | Tools | Tip |

|---|---|---|---|

| Smooth floor (epoxy, tile) | Sweep into scoop → PE bag | Nylon broom + plastic scoop | Sweep from outside in |

| Rough concrete | Industrial vacuum | Explosion-proof vacuum (Class II) | Use HEPA filter |

| Water | Skim with net or skimmer | 1mm nylon mesh | Powder floats → easy to skim |

Step 6: Oil Recovery & Reuse (Optional – 5 Minutes)

| Equipment | Method | Result |

|---|---|---|

| 500rpm centrifuge | Pour into filter bag → spin 3 min | Recovers 70–80% oil → powder reusable 3–5 times |

| Manual press (small scale) | Use cloth or garlic press | Recovers 50% oil |

Step 7: Final Surface Wipe – No Residue (2 Minutes)

| Surface | Cleaning Solution | Method |

|---|---|---|

| Epoxy/tile | Warm water + bio-soap (1:100) | Wipe with microfiber cloth |

| Concrete | Water + white vinegar (1:1) | Scrub lightly with nylon brush |

| Steel/machinery | Neutral solvent (70% IPA) | Wipe with lint-free cloth |

Step 8: Record Report – Legal Compliance

| Record Item | Sample |

|---|---|

| Incident time | 14:30, Nov 12, 2025 |

| Oil type + volume | Diesel, 20L |

| Area | 10m² |

| Powder used | 5kg |

| Cleanup time | 12 minutes |

| Operator | Nguyen Van A |

| Signature | [Sign] |

Step 9: Waste Disposal – 2 Safe Methods

| Method | Conditions | Procedure |

|---|---|---|

| A. Biodegradable burial | Garden, isolated area | Dig 50cm pit → spread powder → cover with soil → apply microbes monthly |

| B. Industrial incineration | Furnace >800°C with air filter | Send to licensed hazardous waste facility |

Never discharge into drains → fine 50–500 million VND.

Special Notes for Real Scenarios

| Scenario | Note | Solution |

|---|---|---|

| Oil spill in rain | Powder floats, but rain dilutes | Use boom + apply powder immediately |

| Oil in narrow machine gaps | Powder cannot enter <2mm gaps | Use N-Sorbents fiber version (special edition) |

| Oil >60°C | Efficiency drops 30% | Cool first → then apply |

| Nighttime spill | Need explosion-proof lighting | Use Zone 1 LED floodlights |

5. Real-World Applications of N-Sorbents Oil absorbent powder: From Industry to Household

N-Sorbents oil absorbent powder is multi-terrain: concrete, soil, river/sea water. Below are key applications with Vietnam case studies (2024–2025):

5.1. Industrial & Transportation

- Oil refineries, auto garages: Cleans machine oil on epoxy floors, reduces slip hazards and downtime.

- Seaports & fuel depots: Collects leaking bunker oil with booms.

- Case Study: Cat Lai Port (HCMC, 2024): 200kg N-Sorbents oil absorbent powder cleaned 800L bunker oil in 25 minutes, 98% recovery, no coastal impact.

5.2. Agriculture & Environment

- Rice fields, rivers: Absorbs vegetable oil or pesticide spills.

- Restaurants, industrial kitchens: Removes cooking oil without odor.

- Case Study: Vinh Tan Power Plant (Binh Thuan, 2025): 520kg cleaned 2,000L fuel oil, surface clean after 8 months natural degradation.

5.3. Personal & Emergency Use

- Home garage or highway oil spills.

- Case Study: Toyota Ly Thuong Kiet Garage (Hanoi, 2024): 4kg cleaned 15L engine oil, floor dry in 10 minutes.

Research from ScienceDirect (2018) shows sorbents like N-Sorbents oil absorbent powder reduce cleanup time by 50% vs. traditional mechanical methods.

N-Sorbents oil absorbent powder in industrial oil spill treatment

6. Comparison with Other Products: Why Choose N-Sorbents Oil Absorbent Powder?

| Criteria | N-Sorbents (Nano-Cellulose) | Polypropylene (3M) | Vermiculite (Mineral) | Sand |

|---|---|---|---|---|

| Absorption (L/kg) | 4 (hydrocarbons) | 8–12 | 0.5–1 | 0.1 |

| Biodegradability | 100% (6–12 months) | 0% | 50–70% | 0% |

| Reuse Cycles | 3–5 | 5–10 | 1–2 | None |

| Cost (VND/kg) | 25,000–35,000 | 80,000 | 15,000 | 5,000 |

| Environmental Safety | High (non-toxic) | Low (chemical) | Medium | Low |

N-Sorbents oil absorbent powder excels in sustainability and cost-effectiveness, ideal for Vietnamese businesses.

7. Safety, Storage & Waste Management: Comprehensive Guide

7.1. Usage Safety

- Certifications: MSDS, REACH Compliant, PFAS-free.

- Precautions: Full PPE; avoid contact with hazardous chemicals. For flammable oils, collect in fireproof containers.

7.2. Product Storage

- Temperature: 5–35°C; Humidity: <60%.

- Shelf life: 36 months (up to 48 with silica gel).

- Store in dry, shaded area.

7.3. Post-Use Waste Disposal

- Preferred: Biodegradable burial away from water sources.

- Alternative: Incineration in industrial furnace (emits only 0.8 kg CO₂ per liter oil cleaned).

8. Frequently Asked Questions (FAQ): All About N-Sorbents Oil Absorbent Powder

- Does N-Sorbents absorb water? No — hydrophobic nano-coating targets only oil-based substances.

- Can it be used on cooking oil or water-based paint? Yes, effective on water-miscible liquids like cooking oil or latex paint.

- How long to biodegrade? 6–12 months in natural conditions (lab-tested).

- Price and where to buy? 25,000–35,000 VND/kg; available at bignanotech.com or nationwide dealers.

- Can powder be reused? Yes — centrifuge to recover oil, reuse 3–5 times.

- Any odor? No — completely neutral.

- Safe on epoxy or concrete? Yes — non-abrasive.

- How much for 100L oil? ~25kg (varies by oil type).

- Export available? Yes — exported to Japan and Singapore.

- Better than sand?40x more effective, fully biodegradable.

9. Conclusion: N-Sorbents Oil Absorbent Powder– Vietnam’s Green Solution for a Cleaner Future

N-Sorbents oil absorbent powder is more than a spill cleanup tool — it’s proof of Vietnamese nano-technology’s power in environmental protection. With 4L/kg absorption, 100% biodegradability, and versatile applications, it minimizes oil spill damage, saves costs, and ensures legal compliance. Studies from ACS and PubMed validate the potential of cellulose sorbents like N-Sorbents oil absorbent powder to replace chemical materials, supporting sustainable development goals by 2030.

If you face oil spill risks, try N-Sorbents oil absorbent powder today and experience the difference.

Act Now: Call (+84) 878 080 808 for orders or free consultation. Visit bignanotech.com for related products like N-Biopowder.

Microbiological powder N-Biopowder from Bignanotech