Oil spills are a serious problem for industries that store and handle petroleum products. Whether you run a factory, warehouse, or lab, an oil spill can be a costly and messy issue. Understanding what an oil spill is, how it happens, and what you can do to prevent it is crucial for your business.

Let’s break it down in simple terms so you can stay informed and prepared.

What is an Oil Spill?

An oil spill happens when oil or petroleum-based products accidentally leak or are released into the environment. This can occur on land or water and can have harmful effects on people, animals, and nature.

Spills can happen anywhere oil is stored, transported, or used – like warehouses, factories, and chemical storage facilities. Even a small spill can cause big problems if not handled correctly.

Key Takeaway:Oil spills can be dangerous and expensive to clean up. Prevention and quick response are essential.

Common Causes of Oil Spills

Oil spills can happen for many reasons, and most of them are preventable. Here are some of the most common causes:

- Human Error: Spills often happen due to mistakes during handling, transferring, or storing oil.

- Equipment Failure: Leaks and spills can result from faulty pipes, tanks, or valves.

- Poor Maintenance: Rust, corrosion, and lack of regular inspections can lead to leaks over time.

- Accidents: Vehicle collisions, machinery malfunctions, and fires can cause unexpected spills.

- Natural Disasters: Floods, storms, and earthquakes can damage storage tanks and pipelines.

- Illegal Dumping: Some businesses improperly dispose of oil, which can lead to contamination and penalties.

Key Takeaway: Regular inspections, proper training, and good storage practices can prevent most spills.

Effects of Oil Spills

An oil spill can affect your business in many ways. It’s not just about the cleanup cost—it can harm the environment, damage your reputation, and even lead to legal trouble.

1. Environmental Impact

- Oil can contaminate soil and water, making it unsafe for plants and animals.

- Spills in water bodies can spread quickly and harm marine life.

- Cleaning up oil from nature is expensive and time-consuming.

2. Economic Impact

- Cleanup costs can be high, especially if professional services are needed.

- Businesses may face fines and lawsuits for non-compliance.

- Spills can disrupt operations and cause product losses.

3. Health Risks

- Exposure to oil and its fumes can cause respiratory issues, skin irritation, and other health problems.

- Workers handling oil spills without proper gear are at risk of serious health effects.

Key Takeaway: Preventing spills protects your business, the environment, and your employees’ health.

Oil Spill Prevention Strategies

Stopping an oil spill before it happens is always the best solution. Here are some simple ways to keep your facility safe:

- Proper Storage: Use leak-proof tanks and store oil away from high-traffic areas.

- Routine Inspections: Regularly check tanks, pipes, and equipment for leaks or wear and tear.

- Employee Training: Train staff on safe handling, storage, and emergency response procedures.

- Secondary Containment: Use spill barriers, dikes, and trays to contain leaks before they spread.

- Spill Kits: Keep spill kits readily available to clean up small leaks before they become big problems.

- Labeling: Clearly label oil storage areas to avoid mishandling.

- Compliance: Follow local regulations and guidelines to ensure safe oil storage and handling.

Key Takeaway: Prevention measures save money and help businesses avoid unnecessary risks.

Oil Spill Response and Cleanup Techniques

Even with the best prevention measures, spills can still happen. Knowing how to respond quickly is crucial.

Immediate Steps to Take

- Contain the Spill: Use absorbent materials, booms, or barriers to stop the spread.

- Alert Your Team: Inform key personnel and follow your emergency response plan.

- Protect Yourself: Wear protective gear before handling oil cleanup.

- Stop the Source: Shut off valves or transfer oil to another container if possible.

Cleanup Methods

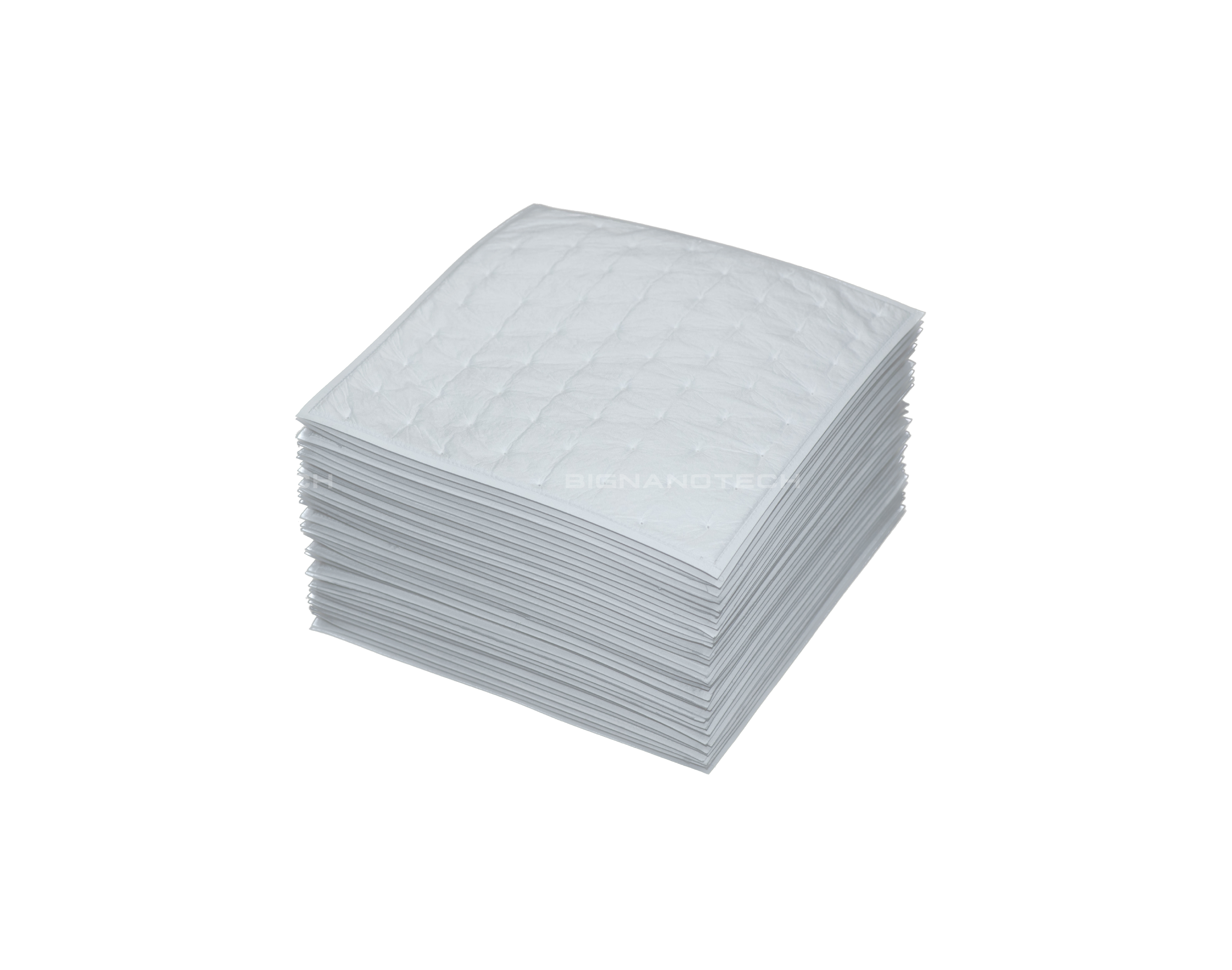

- Absorbents: Use pads, mats, or granular absorbents to soak up the spill.

- Skimmers: These are useful for recovering oil from water surfaces.

- Dispersants: Chemicals that break down oil and help it degrade faster.

- Bioremediation: Using microbes to naturally break down spilled oil.

Key Takeaway: A fast response can minimize damage and cleanup costs.

Oil Spill Regulations and Compliance

Every business handling oil must follow strict rules to prevent spills and protect the environment. Regulatory bodies such as:

- EPA (Environmental Protection Agency) – Oversees oil spill regulations in the U.S.

- OSHA (Occupational Safety and Health Administration) – Ensures worker safety during oil handling.

- MARPOL (Marine Pollution Regulations) – Focuses on preventing marine oil spills.

Non-compliance with these rules can result in hefty fines and legal trouble. Regular training and audits can help your business stay compliant.

Key Takeaway: Staying compliant with regulations helps avoid fines and legal risks.

Best Practices for Spill Containment in Industrial Settings

Here are a few best practices that can help you prepare for and manage spills effectively:

- Have a spill response plan in place and practice it with your team.

- Conduct regular safety drills to ensure your staff is prepared for emergencies.

- Invest in high-quality spill kits designed for your specific type of oil or chemicals.

- Work with a professional spill response company for large-scale incidents.

Key Takeaway: Being prepared for spills minimizes downtime and potential risks.

When to Call a Professional Spill Response Team

While small spills can be handled in-house, larger spills need professional attention. You should call a spill response team when:

- The spill is too large to contain with available resources.

- Oil has reached water sources or sensitive areas.

- Specialized equipment is required for cleanup.

- Regulatory reporting and documentation are needed.

Key Takeaway: Don’t take risks—call the experts for major spills.

Conclusion

Oil spills are a serious risk for any business that handles petroleum products. Understanding the causes, effects, and prevention strategies can help protect your facility, employees, and the environment.

By investing in proper training, storage, and spill response tools, you can reduce the chances of a costly spill and keep your operations running smoothly.

Frequently Asked Questions (FAQs)

1. What should I do immediately after an oil spill?

Contain the spill, alert your team, wear protective gear, and stop the source if possible.

2. What are the most effective oil spill cleanup methods?

Absorbents, skimmers, dispersants, and bioremediation are commonly used techniques.

3. How can I prevent oil spills in my facility?

Regular inspections, proper storage, employee training, and spill response planning are key.

4. Are there legal penalties for oil spills?

Yes, non-compliance with spill regulations can result in heavy fines and legal actions.

Want to stay prepared? Contact Big Nano Technology today for expert spill solutions and prevention strategies tailored to your business needs.