1. Response Principles

The principles for responding to oil spill incidents are clearly stated in Article 4 of Decision No. 12/2021/QĐ-TTg dated March 24, 2021, by the Prime Minister, which promulgates the Regulations on Oil Spill Response Activities; and Guidance No. 2341/HD-STNMT dated September 27, 2022, by the Department of Natural Resources and Environment:

- Receive information, evaluate and conclude clearly and specifically, proactively develop and adjust response plans accurately, effectively leveraging the comprehensive strength of the four on-site principles for timely and effective response;

- Report promptly as required;

- Coordinate and mobilize all resources to enhance the effectiveness of oil spill preparedness and response, prioritizing activities to rescue victims and protect the environment;

- Ensure safety for people and equipment before, during, and after responding to the incident;

- Unified command, closely coordinate and collaborate among all forces, equipment, and devices participating in the response activities.

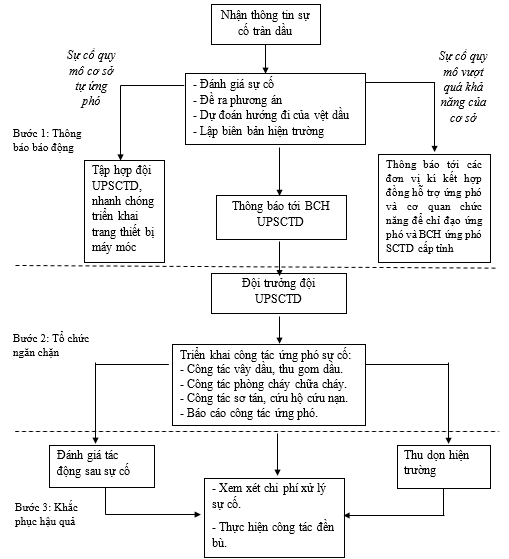

2. Response Deployment Diagram

3. Anticipated Spill Scenarios and Response Measures

- Scenario 1: Oil spill during the transfer of fuel from a tanker to a storage tank

- Location: Area around the 120m3 fuel storage tank.

- Cause: During the transfer of fuel from the tanker to the store’s tank, the connection hose from the tanker was not secure, leading to a strong pressure that caused the hose to disconnect, spilling oil outside instead of into the tank. The store was not operating during the transfer, limiting the number of vehicles and people in the vicinity.

- Time of occurrence: During the day, staff were on duty, and the incident was immediately reported.

- Spilled oil volume: 0.5 – 1m3. The incident was detected in time and was within the facility’s self-response capacity. Normal weather conditions, no rain.

- Direction and scope of oil spread: Flowing downhill towards the collection trench and sump.

- Available forces and equipment: Store manager and sales staff. The store has emergency spill response equipment.

- Advantages: Small oil volume, timely detection.

- Challenges: During the day with high customer traffic, requiring additional personnel to block the area from customers.

- Scenario 2: Oil spill due to leakage from storage tank (Beyond the facility’s self-response capacity)

- Location: Area around the oil storage tank.

- Cause: The tank, built long ago, had its surrounding wall collapse due to a storm, causing the tank cover to fall off and oil to spill.

- Leaked oil volume: Over 1m3.

- Time of occurrence: At night, unexpected heavy rain caused flooding around the store, leading to oil spreading to the surroundings.

- Available equipment: Emergency spill response equipment. The present personnel included the store manager and sales staff.

- Challenges: Nighttime and heavy rain complicating the response.

- Scenario 3: Fire and explosion incident due to traffic collision

- Location: Sales area.

- Cause: Oil spill due to vehicles colliding with fuel pumps, smoke, and engine heat causing a fire.

- Time of occurrence: Daytime, the spill response team was in action, and the incident was immediately reported.

- Direction and scope of oil spread: Minor collision, minimal impact on people and vehicles. Oil spread on the surface contained by sand, oil-absorbent paper, and booms, limiting the fire’s scale to the oil spill area. Estimated spill volume: 0.2m3.

- Advantages: Small oil volume, available response equipment.

- Challenges: Daytime with high customer traffic, requiring additional personnel to block the area from customers.

- Scenario 4: Oil spill at the pipeline area

- Location: Area around the pipeline leading to the fuel pumps.

- Cause: Long-term operation without regular maintenance and inspection led to residue buildup, pipe rupture, or breakage due to various reasons.

- Spilled oil volume: 10-100 liters (pipeline capacity under 100 liters, flowing downhill towards the underground tank).

- Available forces and equipment: Store’s spill response team and company staff. Emergency spill response equipment available.

- Advantages: Small oil volume, timely detection.

4. Response Measures

- Receive information and assess the situation.

- Activate the spill response command mechanism.

- Establish a command center at the scene for directing the response.

- Organize the spill response team.

- Collect waste and handle the aftermath of the incident.

5. Common Spill Response and Handling Products

- Oil Absorbent Pads: Clean machinery, oil-covered equipment, or float on water to absorb surface oil. Suitable for various positions within gas stations, such as fuel pump handles, filling areas, storage areas, and pumping areas.

- Oil Absorbent Booms: Used to contain and isolate large oil spill areas, preventing further spread into the environment. These booms can both contain and absorb oil, facilitating quicker and more convenient incident response and cleanup.

- Cleaning Powder: Absorbs spilled oil on hard surfaces thoroughly, cleaning oil stains without needing other cleaning agents. Easy to use and suitable for spills on floors and paved areas.

- Spill Kit: Essential for all fuel business and storage facilities. Typically includes safety equipment, oil absorbents, brooms, containers, and user instructions to ensure quick response to any spill incident.

6. Suppliers of Oil Absorbent Materials for Gas Stations

BIGNANOTECH specializes in manufacturing and distributing industrial oil absorbent and cleaning products for fuel business and storage facilities, such as oil absorbent pads, oil absorbent booms, oil absorbent pillows, absorbent cotton, spill kits, and industrial cleaning tools. These products provide solutions for industrial cleaning and handling oil/chemical spill incidents both on land and water. The products are treated for anti-static properties, non-explosive, non-flammable, and safe for storage and use.

For more information on products and industrial cleaning solutions, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com