In today’s fast-paced industrial landscape, spills involving oil, chemicals, or hazardous liquids are an ever-present risk. A single drop of oil spreading across a river, a splash of acid in a laboratory, or a mixture of liquids leaking in a factory can trigger severe consequences: environmental contamination, operational downtime, costly cleanup, and potential fire hazards. According to the U.S. Environmental Protection Agency (EPA), unaddressed spills can cause long-term damage to ecosystems, water sources, and public health.

Bignanotech Vietnam, leveraging cutting-edge Japanese Nano technology, introduces a breakthrough solution: absorbent pads designed for superior performance, safety, and environmental sustainability. These absorbent pads excel in absorbing spills, are fire-safe with anti-static treatment, reusable, cost-effective, and compact for use in diverse settings—from gas stations and manufacturing plants to laboratories and open waters.

In this comprehensive guide, we explore three flagship products: Oil Absorbent Pads N-FIBER P45, Chemical Absorbent Pads H-FIBER HM45, and Universal Absorbent Pads G-FIBER GM45. Dive into their specifications, real-world applications, usage instructions, and tips to choose the right pad for your needs, ensuring both operational efficiency and environmental protection.

Bignanotech Absorbent Pads for Oil & Chemical Spills

Why Absorbent Pads Are Critical for Modern Industries

Imagine managing a food processing plant, a gas station, or a research laboratory. A minor incident—oil leaking from machinery, chemicals spilling from containers, or mixed liquids spreading across the floor—can escalate into major issues: environmental regulation violations, hefty fines, or workplace safety risks.

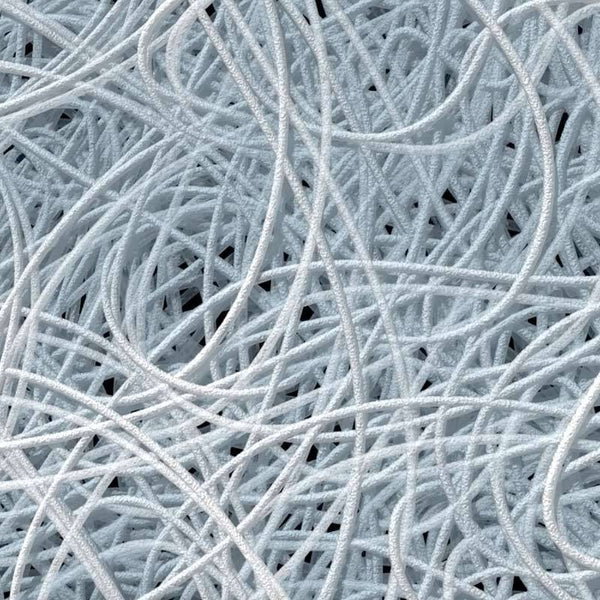

This is where Bignanotech’s absorbent pads shine as indispensable tools. Crafted from 100% polypropylene and powered by Japanese Nano technology, these absorbent pads deliver unmatched absorption efficiency, fire-safe anti-static properties, and the ability to be reused, saving costs and reducing waste. Their compact design makes them versatile for any environment, from rivers and seas to factory floors and confined lab spaces.

Let’s delve into each product to understand how they safeguard your operations and the environment.

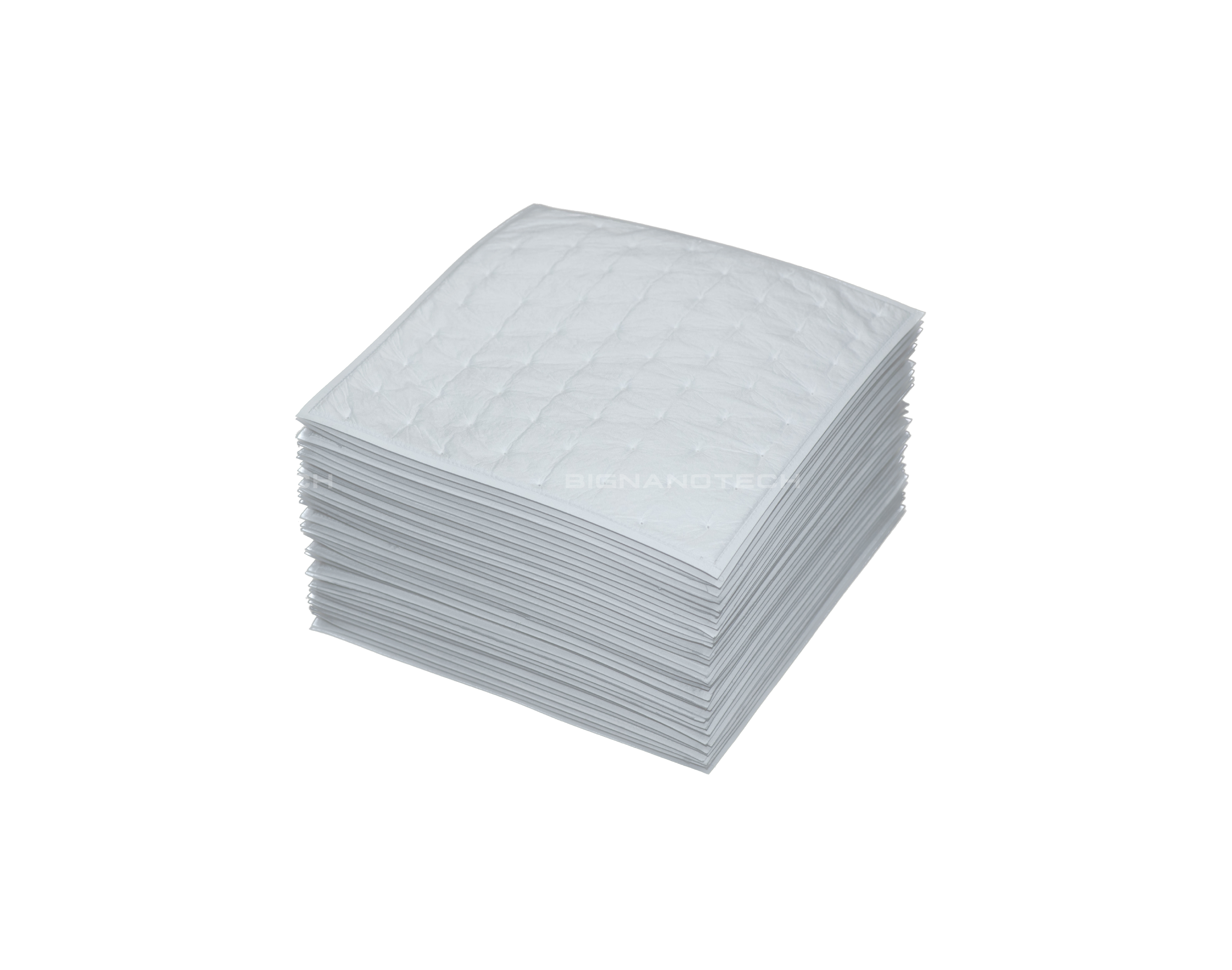

1. Oil Absorbent Pads N-FIBER P45: The Ultimate Defense Against Oil Spills

N-FIBER P45 pads absorbing oil slicks on a river

Technical Specifications

- Product Code: N-FIBER P45

- Material: 100% Polypropylene

- Color: White

- Dimensions: 40cm x 50cm x 0.5cm

- Absorption Capacity: 1.6L per pad

- Packaging: 100 pads per box

- Origin: Bignanotech Vietnam

- Safety Standard: Anti-static, compliant with fire-prone environments

Key Features

The N-FIBER P45 is engineered specifically for oil, fuel, lubricants, diesel, and other oil-based liquids. Powered by Japanese Nano technology, it offers exceptional performance in diverse conditions:

- Rapid Absorption: Perforated surface design accelerates oil absorption 2-3 times faster than standard pads, enabling swift spill containment.

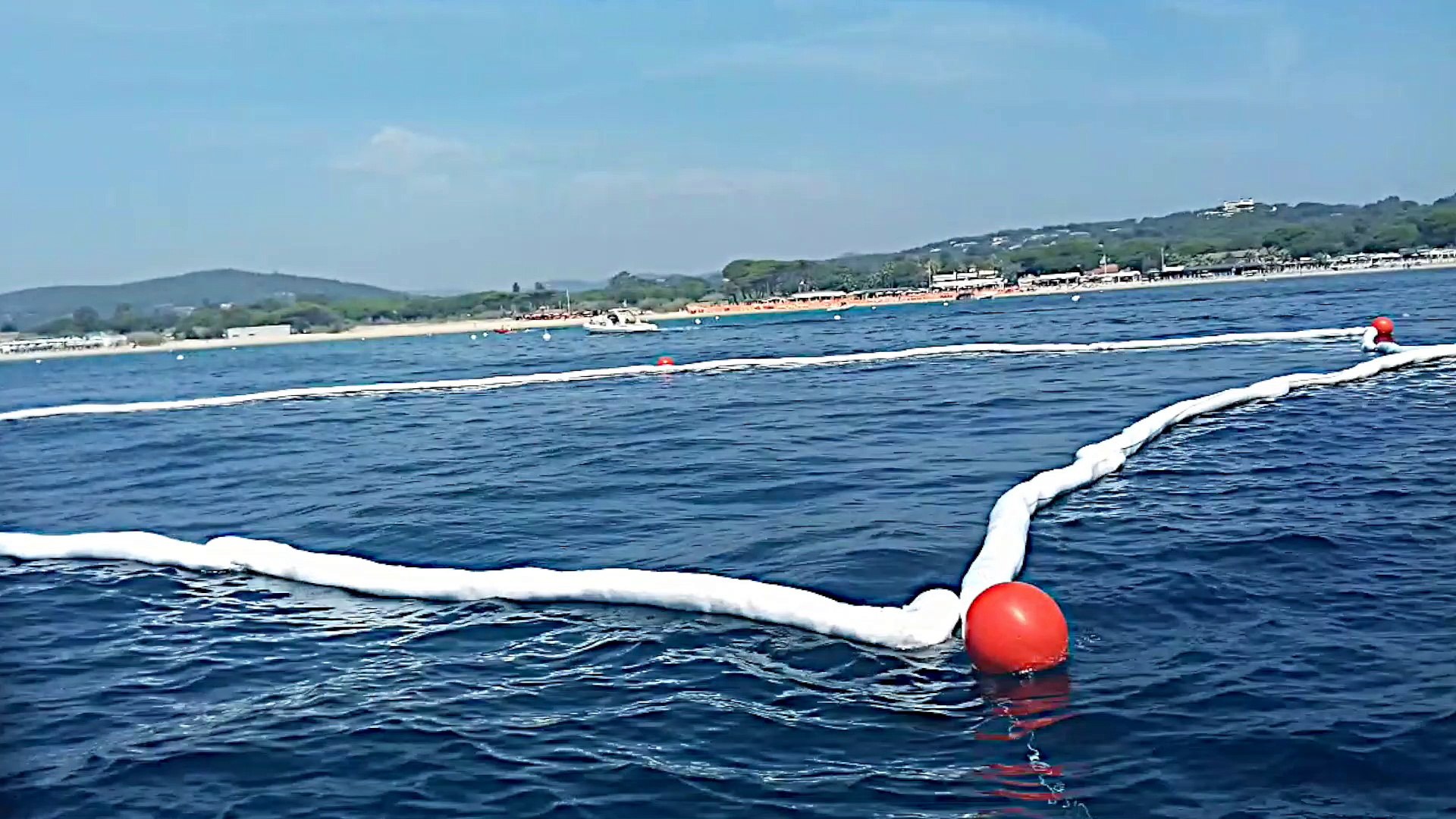

- Water-Repellent: Floats on water to capture oil slicks, remaining buoyant even under waves, currents, rain, or submersion.

- Reusable Efficiency: Retains absorbed oil securely without leakage, even when saturated. Pads can be wrung out and reused 3-5 times, with absorption capacity reducing by ~30% per reuse.

- Fire-Safe: Anti-static treatment ensures safety in fire-prone areas like gas stations, oil depots, or mechanical workshops.

- High Durability: Resists tearing, fraying, mold, and pests when stored properly in standard conditions.

- Compact Design: Measuring 40cm x 50cm, oil absorbent pads are easy to transport and deploy across terrains, from open waters to factory floors.

Real-World Applications

- On Water: Absorbs oil slicks on rivers, seas, lakes, or containment tanks, ideal for large-scale spills at ports or agricultural areas.

- On Floors: Cleans up oil spills in factories, workshops, gas stations, equipment storage areas, or construction sites.

- Maintenance and Cleaning: Wipes oil from machinery, tools, or equipment during transport, assembly, or maintenance.

- Emergency Response: Perfect for urgent situations like oil spills on farmlands, roads, or outdoor environments.

N-FIBER P45 pads cleaning oil spills on a factory floor

Usage Instructions

- Preparation: Identify the spill area and ensure safe access (wear protective gloves if necessary).

- Deploy Pads: Gently place or spread N-FIBER P45 pads over the oil spill to maximize surface contact.

- Absorption Process: Wait 3-5 minutes, flip the pad, and wait again to fully absorb the oil. The pad darkens when saturated.

- Oil Recovery: Wring out absorbed oil into a designated container for reuse (if needed). Pads can be reused immediately after wringing.

- Post-Use Handling: Store saturated pads in a hazardous waste storage area, away from heat sources or flames, and avoid direct environmental disposal.

Tips for Use:

- Deploy multiple absorbent pads simultaneously for large oil spills or stack them in areas with thick oil layers.

- On water, position pads in areas with gentle currents for optimal absorption.

- Store pads in a dry, well-ventilated area to maintain durability.

2. Chemical Absorbent Pads H-FIBER HM45: Robust Protection Against Hazardous Chemicals

H-FIBER HM45 pads absorbing acid in a laboratory

Technical Specifications

- Product Code: H-FIBER HM45

- Material: 100% Polypropylene

- Color: Pink/Yellow

- Dimensions: 40cm x 50cm

- Absorption Capacity: 1.1L per pad

- Packaging: 100 pads per box

- Box Weight: ~6.5kg

- Origin: Bignanotech Vietnam

- Safety Standard: Anti-static, suitable for hazardous environments

Key Features

The H-FIBER HM45 is designed to tackle acids, bases, corrosives, and hazardous chemicals, including high-concentration solutions like 98% sulfuric acid or 30% sodium hydroxide. It meets stringent safety requirements for chemical-intensive environments:

- Versatile Absorption: Effectively absorbs a wide range of hazardous liquids, from strong acids and bases to unidentified chemicals, ensuring safe spill containment.

- High-Visibility Color: Pink/yellow hue enhances visibility for quick identification in emergency situations, especially in labs or chemical storage areas.

- Fire-Safe: Anti-static treatment ensures safety in fire-prone settings like chemical warehouses or battery manufacturing plants.

- Non-Reactive: Does not degrade or trigger hazardous reactions when exposed to corrosive substances, ensuring safe handling.

- Superior Durability: Resists tearing even when saturated, offering long-term reliability.

- Compact Design: 40cm x 50cm size facilitates easy transport and use in confined spaces like laboratories.

Real-World Applications

- Laboratories: Absorbs chemical spills from experimental equipment, containers, or research processes.

- Chemical Warehouses: Manages chemical leaks in storage, transport, or hazardous waste processing areas.

- Manufacturing Plants: Cleans chemicals in production processes, particularly in industries like chemicals, batteries, plastics, or cleaning agents.

- Industrial Zones: Ideal for areas at risk of chemical leaks, such as paint, pharmaceutical, or waste treatment facilities.

H-FIBER HM45 pads cleaning chemicals in a manufacturing plant

Usage Instructions

- Safety Gear: Wear protective gloves, clothing, goggles, and masks to avoid direct contact with hazardous chemicals.

- Deploy Pads: Place H-FIBER HM45 chemical absorbent pads over the chemical spill, ensuring maximum surface contact.

- Absorption Process: Wait 3-5 minutes, flip the pad, and wait again to fully absorb the chemical. The chemical absorbent pads darkens when saturated.

- Chemical Recovery: Wring out absorbed chemicals into a designated container (if reuse is needed). Pads can be reused immediately after wringing.

- Post-Use Handling: Store saturated pads in a hazardous waste container or designated storage area, away from heat sources or flames, and avoid direct environmental disposal.

Warnings:

- Saturated pads may retain hazardous properties of absorbed chemicals. Handle with care and follow hazardous waste regulations.

- Ensure proper ventilation and full protective gear when handling strong acids or toxic chemicals.

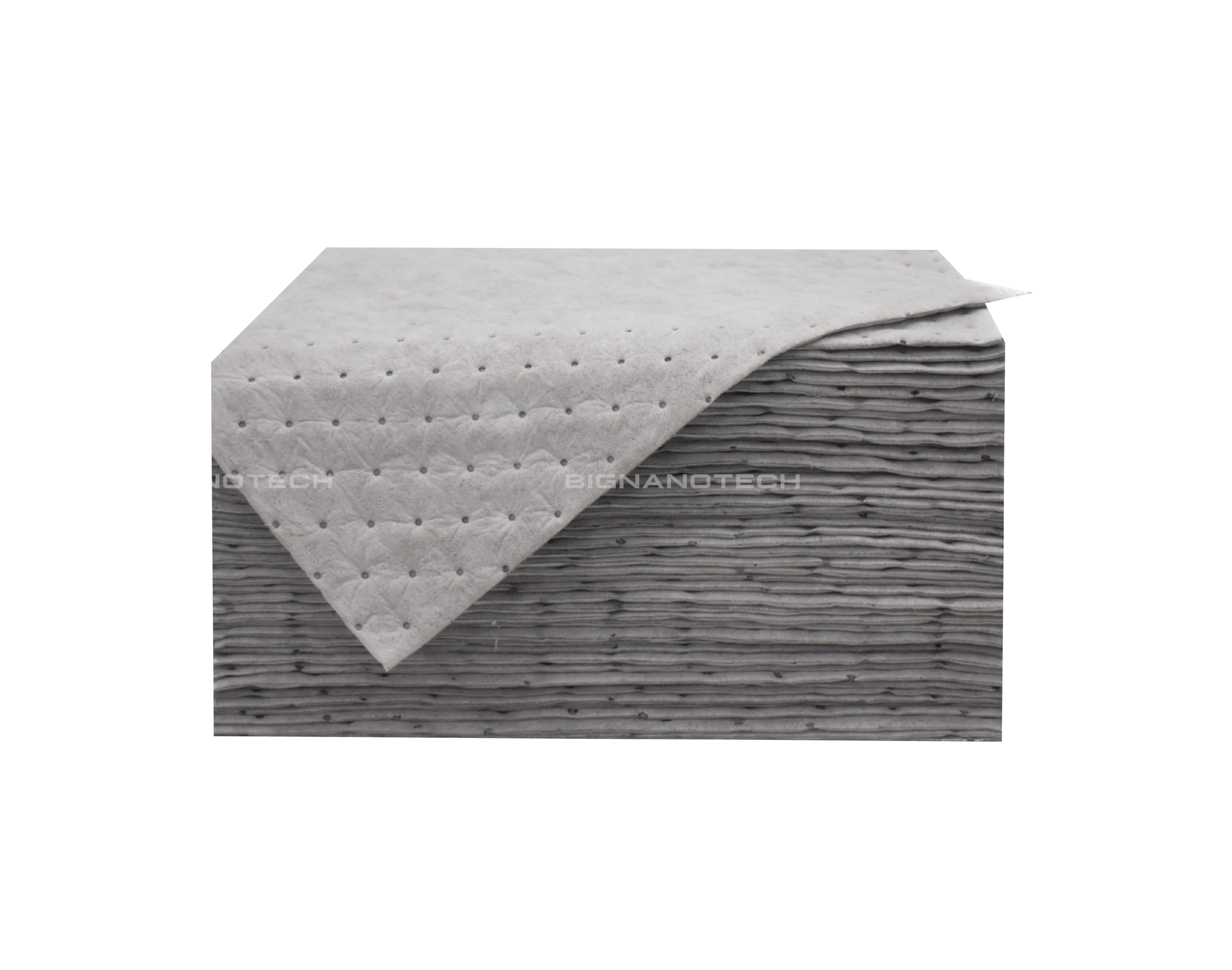

3. Universal Absorbent Pads G-FIBER GM45: Versatile Solution for All Liquids

G-FIBER GM45 pads managing mixed liquids in a factory

Technical Specifications

- Product Code: G-FIBER GM45

- Material: 100% Polypropylene

- Color: Gray

- Dimensions: 40cm x 50cm

- Packaging: 100 pads per box

- Box Weight: ~6.8kg

- Origin: Bignanotech Vietnam

- Safety Standard: Anti-static, suitable for industrial environments

Key Features

The G-FIBER GM45 is a versatile solution for environments requiring absorption of multiple liquid types, including oil, water, diluted acids/bases, and moderately hazardous corrosives. Its intelligent design and Japanese Nano technology ensure maximum flexibility:

- Universal Absorption: Absorbs a wide range of industrial liquids, from oil and solvents to water and diluted chemicals, ideal for diverse settings.

- Perforated Design: Enhances absorption speed and allows easy tearing for cost-efficient use, especially for small spills.

- High Durability: Offers twice the lifespan of similar products, resisting tearing or degradation when saturated.

- Eco-Friendly: Easy to store and dispose of, minimizing industrial waste.

- Gray Color Identification: Perfect for mixed liquid environments or diluted chemicals, ensuring easy recognition in factories.

Real-World Applications

- Food Processing Plants: Absorbs cleaning agents, oil, or diluted solutions during production.

- Laboratories and R&D: Manages mixed liquids in research or testing environments.

- Industrial Zones: Cleans oil, chemicals, or water in battery storage areas, dipping tanks, or thermal power, plastics, and chemical plants.

- Equipment Lining: Used as liners under machinery to prevent liquid leaks in workshops or factories.

G-FIBER GM45 pads used as liners under machinery

Usage Instructions

- Assessment: Identify the liquid type and spill area to determine the number of pads needed.

- Deploy Pads: Place G-FIBER GM45 pads over the spill, ensuring maximum surface contact.

- Absorption Process: Wait 3-5 minutes, flip the pad, and wait again to fully absorb the liquid. The pad darkens when saturated.

- Liquid Recovery: Wring out absorbed liquids into a designated container (if needed). Pads can be reused immediately after wringing.

- Post-Use Handling: Store saturated universal absorbent pads in a hazardous waste storage area, away from heat sources or flames, and avoid direct environmental disposal.

Tips for Use:

- Use G-FIBER GM45 as liners under machinery to prevent leaks in factories.

- Tear pads along perforations for efficient use on small spills.

- Combine with N-FIBER P45 or H-FIBER HM45 for complex spills involving multiple liquid types.

Comparison and Guide to Choosing the Right Absorbent Pad

| Criteria | N-FIBER P45 | H-FIBER HM45 | G-FIBER GM45 |

| Liquid Type | Oil, fuel, lubricants | Acids, bases, hazardous chemicals | Oil, water, diluted acids/bases |

| Absorption Capacity | 1.6L per pad | 1.1L per pad | Flexible, depends on liquid |

| Color | White | Pink/Yellow | Gray |

| Primary Applications | Gas stations, rivers, factories | Labs, chemical warehouses | Factories, versatile industrial use |

| Reusability | 3-5 times | Yes (depends on chemical) | Yes (depends on liquid) |

| Fire Safety | Anti-static | Anti-static | Anti-static |

When to Use Each Pad?

- N-FIBER P45: Ideal for large oil spills, especially on water (rivers, seas, lakes) or in gas stations, mechanical workshops, or construction sites. Perfect for high-volume oil absorption and frequent reuse.

- H-FIBER HM45: Designed for hazardous chemical spills, such as strong acids, bases, or corrosives. Best for laboratories, chemical warehouses, or industrial zones handling chemicals.

- G-FIBER GM45: The go-to choice for versatile environments like food processing plants, R&D labs, or industrial zones with mixed liquids (oil, water, diluted chemicals). Great for equipment lining or diverse spill scenarios.

Tips for Selection Absorbent Pads

- Identify Liquid Type: Choose N-FIBER P45 for oil, H-FIBER HM45 for hazardous chemicals, and G-FIBER GM45 for mixed or diluted liquids.

- Assess Environment: Outdoor settings (rivers, seas) require water-repellent N-FIBER P45. Labs or chemical warehouses need H-FIBER HM45. Versatile factories benefit from G-FIBER GM45.

- Calculate Volume: Estimate spill volume to prepare enough pads. For example, 10L of oil requires ~7 N-FIBER P45 pads (1.6L per pad).

- Combine Products: For complex spills (e.g., oil and chemicals), use N-FIBER P45 and H-FIBER HM45 together for optimal results.

Unique Benefits of Bignanotech Absorbent Pads

- Japanese Nano Technology: Maximizes absorption speed and capacity, outperforming standard products.

- High-Quality Vietnamese Product: No import taxes, competitive pricing compared to premium imports from Australia or the U.S., with stable domestic and international supply.

- Safe and Durable: Anti-static, tear-resistant, long-lasting, and easy to store in standard conditions.

- Cost-Effective: Reusable 3-5 times, reducing storage space and cleanup costs.

- Eco-Friendly: Supports compliance with environmental regulations, minimizing hazardous waste.

Conclusion: Comprehensive Solutions for Spill Management

Bignanotech’s absorbent pads stand as a cornerstone for modern industries, offering unmatched solutions to tackle oil, chemical, and mixed liquid spills while ensuring operational efficiency, workplace safety, and environmental sustainability. Whether you’re managing a gas station, a laboratory, a food processing plant, or a marine operation, these absorbent pads provide tailored answers to your spill challenges.

For oil spills, N-FIBER P45 absorbent pads are your ultimate choice, excelling in rapid absorption on water or factory floors, with the ability to float and be reused 3-5 times, making them ideal for high-volume spill cleanup at ports, rivers, or mechanical workshops.

For hazardous chemical spills, H-FIBER HM45 absorbent pads offer robust protection, safely handling strong acids, bases, and corrosives in laboratories or chemical warehouses, with anti-static properties ensuring safety in fire-prone environments.

For versatile settings with mixed liquids, G-FIBER GM45 absorbent pads deliver flexibility, absorbing oil, water, and diluted chemicals, perfect for food processing plants, R&D labs, or as equipment liners in industrial zones.

To maximize effectiveness, always identify the liquid type to select the appropriate absorbent pad, assess the environment to ensure compatibility (e.g., water-repellent pads for outdoor spills), calculate spill volume to prepare sufficient absorbent pads (e.g., 10L oil requires ~7 N-FIBER P45 pads), and combine N-FIBER P45 absorbent pads with H-FIBER HM45 absorbent pads for complex spills involving multiple liquids.

With Japanese Nano technology, these absorbent pads offer superior absorption speed, durability, and eco-friendly reusability, reducing costs and waste while meeting stringent environmental regulations. Equip your business with Bignanotech absorbent pads to stay prepared for any spill scenario, ensuring a safer, greener future.

Contact Now: Visit Bignanotech or connect via Zalo for detailed consultations and orders, and let Bignanotech absorbent pads safeguard your operations today!

- Website: https://bignanotech.com

- Hotline: (+84) 879 808 080 | (+84) 868 939 595

- Email: sales@bignanotech.com

- Address: The Manor Tower A, Me Tri Road, My Dinh 1, Nam Tu Liem, Hanoi