In the context of increasingly stringent environmental regulations (pursuant to Decree 45/2022/ND-CP and Decision 24/2025/QĐ-TTg), treating oil-contaminated wastewater and responding to oil spills have become critical challenges for factories, seaports, mechanical workshops, and petroleum enterprises. N-Fiber oil filter fabric from Bignanotech – a 100% Vietnamese-manufactured product applying Japanese nano technology – is leading the market thanks to its extremely high selective oil absorption capacity, allowing water to pass through at high flow rates while thoroughly retaining oil.

Below is the most updated and detailed introduction to this product to help you easily evaluate and apply it.

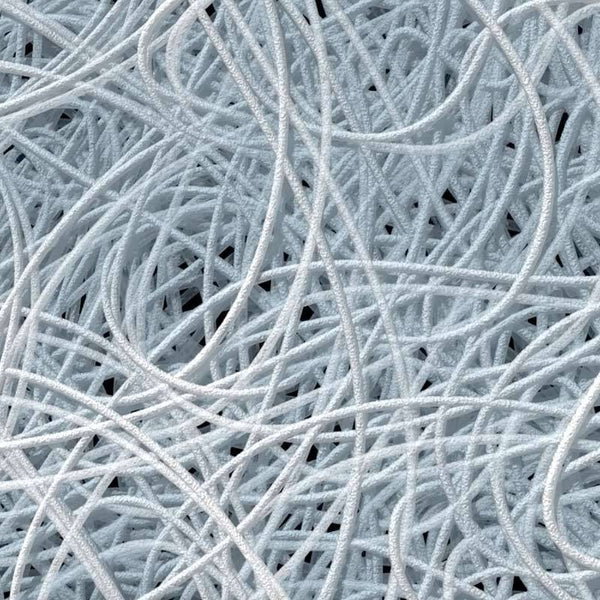

N-Fiber Oil Filter Fabric from Bignanotech

Why N-Fiber Oil Filter Fabric Stands Out Compared to Conventional Oil Absorbent Materials?

Most traditional polypropylene oil absorbent materials only absorb oil and block water entirely. N-Fiber oil filter fabric is different:

- 100% selective oil absorption – retains only oil & oil-based chemicals, completely hydrophobic

- Allows water to pass through with extremely high flow rate: up to 250 m³/hour/m²

- Absorbs oil up to 20 times its own weight (equivalent to ~1.75 kg oil/m² depending on oil type)

- Reusable 3–10 times (oil separated by mechanical wringing/pressing/centrifugation)

- Ultra-fine nano fibers (< 30 nm) → increases surface contact area, 30% higher efficiency than conventional types

Here are real images of the N-Fiber oil filter fabric product and how it operates when treating oil slicks on water:

Detailed Technical Specifications (Popular Model N-FIBER Oil Filter Fabric F75)

| Technical Parameter | Value / Feature |

|---|---|

| Material | 100% Recycled Polypropylene + Japanese Nano Technology |

| Thickness | ~5 mm (customizable) |

| Weight | 0.5 – 1.75 kg/m² |

| Standard Roll Size | 75 m × 1.5 m (custom cut available) |

| Oil Absorption Capacity | Up to 20 times own weight (~1.75 kg oil/m²) |

| Water Flow Rate | Up to 250 m³/hour/m² |

| Reusability | 3–10 times (depending on environment & oil separation method) |

| Anti-Static | Yes – suitable for explosion-proof areas (petroleum, chemicals) |

| Operating Temperature | -30°C to +120°C |

| End-of-Life Incineration | Ash < 1%, incinerate at 600–800°C |

| Reference Standards | ASTM F716, IMO MARPOL Annex I (used in SOPEP kits) |

Practical Benefits of Using N-Fiber Oil Filter Fabric (Updated 2026)

- Operational Cost Savings

- Completely replaces expensive chemical oil separation systems

- Reduces 30–40% costs compared to imported single-use materials

- Domestic production → no import duties, more competitive pricing than Australian/US products

- Superior Efficiency

- Effectively filters both thin oil slicks and emulsified oil

- No clogging of flow in continuous drainage systems

- Legal Compliance & Risk Reduction

- Compliant with Decision 12/2021/QĐ-TTg & 24/2025/QĐ-TTg on oil spill response

- Avoids fines up to hundreds of millions VND in case of incidents (e.g., Cat Lai Port 2024)

- Environmentally Friendly

- Recycled materials, multiple reuses

- Clean incineration at end-of-life with minimal ash

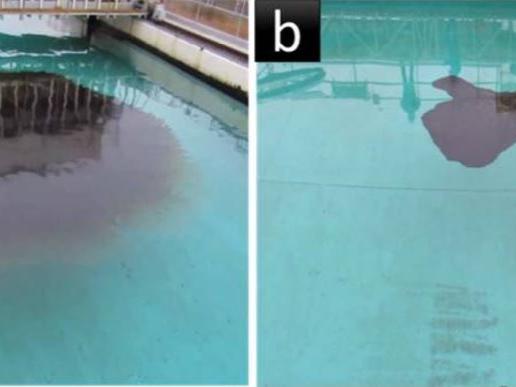

Here are before-and-after images of using N-Fiber oil filter fabric to treat oil-contaminated wastewater:

Most Common Real-World Applications (Widely Deployed in Vietnam)

- Continuous Industrial Wastewater Treatment Mechanical, thermal power, petrochemical, plastic manufacturing factories → installed at discharge drains, three-compartment tanks, drainage channels

- Emergency Oil Spill Response Forms containment curtains at seaports, rivers, lakes; rapidly collects floating oil in 5–10 minutes

- Rainwater & Ship Ballast Water Filtration Prevents oil from factory roofs, yards, vessels entering the environment

- Post-Basic Oil Separation Support Removes remaining thin oil slicks after primary separators

- Explosion-Prone Areas Anti-static, safe for gas stations, fuel storage depots

Real-world example: At a steel factory in Hai Phong, N-Fiber oil filter fabric completely treated an oil spill in one day, saving significant costs compared to traditional methods.

Simple & Safe Usage Guidelines

- Installation → Stretch/clamp the fabric at the filtration point (drain, pipe, containment barrier)

- Operation → Allow oil-contaminated water to flow through naturally

- Monitoring → When fabric saturates with oil (darkens, flow rate decreases) → replace

- Oil Separation → Mechanical wringing/pressing → recover oil for recycling or disposal

- Cleaning → Normal washing (if needed) → reuse

- End-of-Life Disposal → Incinerate at high temperature when fabric is worn out

Illustrative images of practical installation and usage:

Conclusion: N-Fiber Oil Filter Fabric – The Smart Choice for Vietnamese Enterprises in 2026

With advanced nano technology, reasonable pricing, and proven real-world efficiency, N-Fiber oil filter fabric F75 from Bignanotech not only helps enterprises thoroughly resolve oil waste issues but also contributes to sustainable environmental protection.

Are you facing oil-contaminated wastewater problems or need to prepare an oil spill response plan? Contact Bignanotech immediately for free consultation & best quotes:

- Hotline: 0879 808 080/ 094 386 7099/ 0868 939 595

- Email sales@biganotech.com

- website: bignanotech.com

- Theo dõi tại: Facebook Bignanotech , Youtube Bignanotech & Tiktok Bignanotech

Act today – protect the environment, save costs, and avoid legal risks!