In the context of expanding oil and gas extraction, maritime transport, and industrial production in Vietnam, oil spills pose significant economic and environmental threats, jeopardizing aquatic ecosystems, water resources, and public health. According to reports from the Ministry of Agriculture and Environment (post-merger under Decree 62/2025/NĐ-CP), Vietnam records hundreds of minor and major oil spill incidents annually, ranging from offshore tanker accidents to industrial leaks.

The oil absorbent boom (also known as Oil Absorbent Sock or Containment Boom) is a critical oil spill response equipment, enabling rapid containment, encirclement, and absorption of spilled oil. This product not only mitigates pollution but also complies with stringent Vietnamese regulations, such as Decision 12/2021/QĐ-TTg and its amendment under Decision 24/2025/QĐ-TTg on Oil Spill Response Protocols.

This article provides detailed, industry-specific information on oil absorbent boom, covering definitions, types, benefits, technical specifications, practical applications, usage guidelines, relevant regulations, maintenance tips, and post-use handling. The goal is to assist oil and gas companies, port authorities, emergency response centers, and environmental management agencies in selecting and deploying effective solutions to ensure timely response and risk mitigation.

Oil Absorbent Boom

What is an Oil Absorbent Boom? Mechanism and Role in Oil Spill Response

An oil absorbent boom is a specialized floating barrier designed to encircle and absorb oil spills on water or land surfaces. It typically comprises three main components:

- Float: Constructed from buoyant materials like PE (Polyethylene) or PVC, enabling the boom to float freely on rivers, seas, lakes, or flooded areas.

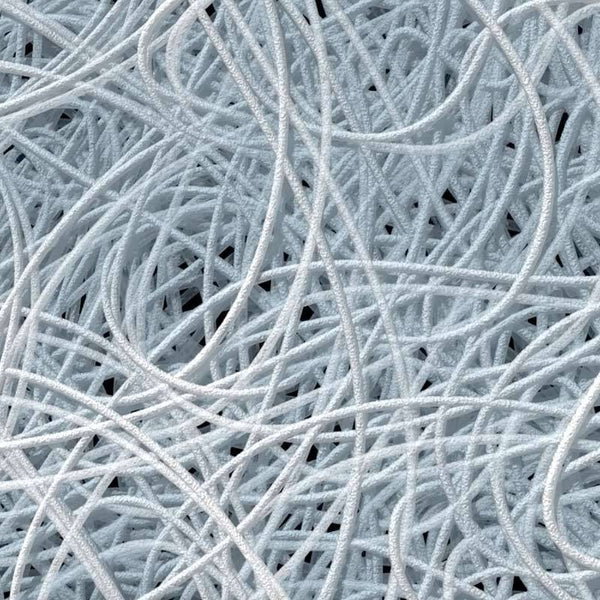

- Absorbent Layer (Skirt): Made from polypropylene (PP) fibers with selective oil absorption properties, repelling water while capturing oil without adding significant weight.

- Ballast Chain: A metal chain or sandbag system to stabilize the boom and prevent oil from spreading beneath the water surface.

The mechanism operates on physical principles: upon deployment, the boom forms a U-shaped or circular barrier around the spill site (containment), while the PP fibers absorb oil via capillary action, retaining it without leakage. According to EPA (U.S. Environmental Protection Agency) studies, oil absorbent boom can absorb 10-20 times their weight in oil, depending on the type (crude oil, diesel, gasoline, etc.).

Oil absorbent boom forms a circular barrier around the spill site

Key roles:

- Containment of Pollution: Protects coastlines, rivers, and aquatic ecosystems from toxic oil spread.

- Oil Recovery Support: Integrates with skimmers to recover up to 90% of spilled oil.

- Emergency Response: Suitable for all response levels under Vietnamese regulations, from local incidents (<20 tons) to national emergencies (>5,000 tons).

Common Types of Oil Absorbent Boom and Specific Applications

Based on design and purpose, oil absorbent boom are categorized to suit Vietnam’s diverse environmental conditions, aligned with international standards from EPA and IMO (International Maritime Organization):

- Containment Booms: Basic models focused on encircling oil. Ideal for calm rivers or industrial sites. Example: SuperSwamp Boom for shallow canals.

- Absorbent Booms: Equipped with PP fibers for direct oil absorption. Best for small spills, such as leaks from auto garages or chemical plants. Absorbs diesel within 5-10 minutes.

- Fire-Resistant Booms: Withstands temperatures up to 1,000°C, used in flammable areas like oil depots. Safe for in-situ burning techniques.

- Exclusion Booms: Designed to protect sensitive areas like beaches or aquaculture zones, preventing oil from reaching shorelines.

- Permanent Booms: Fixed at ports or pipelines for long-term spill prevention.

In Vietnam, these types have been deployed in incidents like the Formosa Ha Tinh spill (2016) and offshore tanker accidents in the East Sea, significantly reducing damages worth billions of VND.

Comprehensive Benefits of Oil Absorbent Booms in Spill Management

Utilizing oil absorbent boom offers economic, environmental, and safety advantages:

- High Efficiency: Reduces response time from hours to 15-30 minutes, containing up to 95% of oil spread (per NOAA – National Oceanic and Atmospheric Administration studies).

- Cost-Effective: Cheaper than chemical dispersants, with reusability 2-3 times for lighter oils.

- Environmental Protection: Prevents toxic oil from entering the aquatic food chain, reducing mass die-offs of fish, seabirds, and corals. Complies with Vietnam’s 2020 Environmental Protection Law.

- Ease of Deployment: Lightweight (5-10 kg/m), compact, and transportable by truck or vessel, requiring no complex equipment.

- User Safety: Non-toxic materials, resistant to winds up to Beaufort scale 5-6, minimizing risks for response teams.

- Long-Term Economic Gains: Lowers cleanup costs (beach remediation can cost millions of USD) and avoids environmental fines up to 2 billion VND (Decree 45/2022/NĐ-CP).

Compared to alternatives, booms outperform dispersants (potential secondary toxicity) and burning (only viable when recovery is unfeasible).

Detailed Technical Specifications of Oil Absorbent Boom from Bignanotech

Based on data from Bignanotech, these products are manufactured with premium materials, adhering to ISO 9001 and Vietnamese environmental standards. Below are expanded technical specifications for popular models:

| Model | Dimensions (cm) | Oil Absorption Capacity (l) | Weight (kg) |

|---|---|---|---|

| N-FIBER B151 | 10 x 150 | 17 | 0.78 |

| N-FIBER B210 | 10 x 200 | 24 | 1.1 |

| N-FIBER B310 | 10 x 300 | 40 | 1.8 |

| N-FIBER B410 | 10 x 400 | 47 | 2.1 |

| N-FIBER B320 | 20 x 300 | 80 | 2.8 |

| N-FIBER B610 | 10 x 600 | 80 | 3.6 |

| N-FIBER B620 | 20 x 600 | 160 | 5.5 |

- Absorption Time: 5-15 minutes for light oil, 20-30 minutes for heavy oil.

- Service Life: 3-5 years if stored dry and shielded from direct sunlight.

- Certifications: Compliant with OPRC (International Convention on Oil Pollution Preparedness and Response) and Vietnamese regulations.

Practical Applications and Case Studies in Vietnam

Oil absorbent boom are applied in various scenarios:

- Offshore and Port Operations: Contained oil from tanker accidents, e.g., the 2023 Din Vu Port spill in Hai Phong, recovering 80% of oil.

- Rivers and Canals: Managed leaks from oil pipelines along the Red River or Mekong Delta.

- Industrial Zones: Controlled oil discharges from chemical plants in Binh Duong or Dong Nai.

- Aquaculture: Protected ponds from oil spills due to agricultural activities.

- Emergency Drills: Used by Environmental Incident Response centers in exercises with oil recovery equipment.

Oil absorbent boom from Bignanotech is used in oil spill emergency drills

Detailed Usage and Maintenance Guidelines for Oil Absorbent Boom

For optimal performance, follow these steps:

- Preparation: Inspect equipment, ensuring availability of accessories (anchor lines, connectors, PPE). Develop a response plan per Decision 63/2014/QĐ-TTg.

- Deployment: Release the boom in a U-shape around the spill, anchoring 1-2m from shore. Use small boats for large areas.

- Recovery: After 10-20 minutes, use skimmers to extract oil. Rinse with clean water if reusing.

- Post-Use Handling: Squeeze oil from the boom, dispose of waste at specialized facilities. Store in a dry area, with bi-annual inspections.

- Safety Notes: Avoid direct oil contact, use PPE. Avoid deployment in large spills without professional support.

Tip: Combine with dispersants for high-wave conditions, but prioritize mechanical recovery to avoid secondary toxicity.

Regulatory Framework for Oil Spill Response in Vietnam

Under Decision 12/2021/QĐ-TTg (amended by 24/2025/QĐ-TTg), entities required to prepare response plans include:

- Oil terminals, vessels carrying >20 tons of oil.

- Oil and gas refineries, chemical plants.

- Offshore extraction companies.

Response Tiers:

- Local Level: <20 tons, managed by the facility.

- Regional Level: 20-5,000 tons, coordinated with local authorities.

- National Level: >5,000 tons, led by the National Committee for Incident, Natural Disaster, and Search and Rescue Response.

Entities must maintain oil spill response equipment, including booms, and report to the Ministry of Agriculture and Environment within 24 hours. Penalties reach 2 billion VND under Decree 45/2022/NĐ-CP.

Frequently Asked Questions (FAQ) About Oil Absorbent Boom

- Can oil absorbent booms be reused? Yes, 2-3 times for light oil, requiring professional squeezing and cleaning.

- What is the approximate cost? Ranges from 500,000 – 2,000,000 VND/ boom, depending on the model; contact suppliers for exact quotes.

- Suitable for heavy oil? Yes, but more effective with light oil; use fire-resistant models for crude oil.

- How to select the right type? Assess spill scale, terrain, and budget; seek expert advice.

- Any certifications? Meets ISO, OPRC, and Vietnamese standards.

Why Choose Oil Absorbent Boom from Bignanotech?

Bignanotech, a trusted supplier in Vietnam, offers high-quality products, competitive pricing, and comprehensive services: free consultations, training, 2-year warranty, and fast delivery. We collaborate with response centers to ensure practical suitability.

Contact us for consultations and quotes on oil absorbent boom:

- Hotline: (+84) 879 080 080

- Email: sales@bignanotech.com

- Website: bignanotech.com

Equip your operations with oil absorbent boom today to protect the environment, comply with regulations, and minimize oil spill risks!