In the context of rapid industrialization and urbanization in Vietnam, oil spills at manufacturing plants, seaports, automotive workshops, rivers, and lakes are no longer rare occurrences. These incidents not only cause economic losses amounting to billions of VND but also pose severe threats to aquatic ecosystems and public health. As Vietnam’s leading enterprise in nano-technology, Bignanotech is committed to delivering smart, highly effective, and environmentally friendly solutions. Today, we present in-depth information about the N-FIBER Oil Absorbent Pad series – a product developed through more than five years of intensive research, combining state-of-the-art Meltblown technology with nano-scale polypropylene fibers to provide enterprises with a fast, safe, and cost-effective oil spill containment and recovery solution.

With the mission “Nano Technology – Sustainable Solutions for the Environment”, Bignanotech does not merely supply products; we partner with over 1,500 large and small enterprises nationwide in establishing comprehensive chemical and oil spill response systems (Spill Response Plan). This article delves deeply into every aspect of N-FIBER – from production technology to real-world applications – based on the latest internal test data (November 2025) and feedback from strategic partners such as Samsung, Petrolimex, and Hoa Phat Group.

Oil absorbent pads quickly handle oil leaks to avoid causing unwanted consequences at gas stations

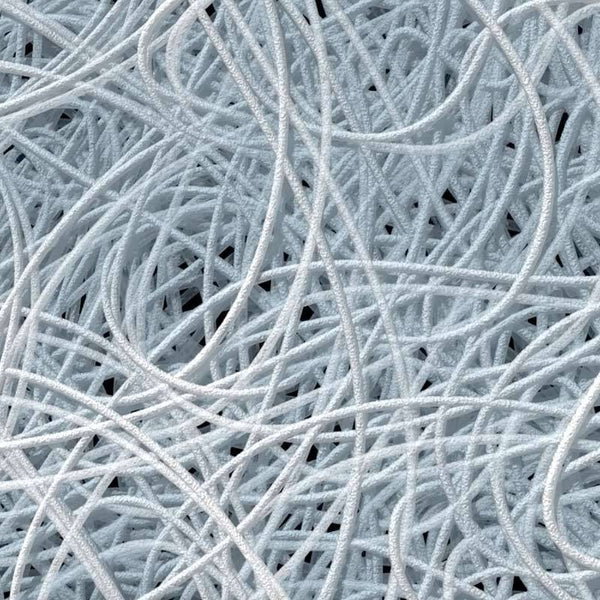

What is N-FIBER? A Closer Look at the Nano-Technology Behind the Product

N-FIBER (Nano-Fiber Oil Absorbent Pad) is a professional “Oil-Only” absorbent pad series manufactured 100% at Bignanotech’s facility in Tien, Hung Ha (Thai Binh, Viet Nam). The product utilizes Meltblown technology – a nano-fiber process in which virgin polypropylene is melted at 250–300°C and extruded through electrostatically charged nozzles to form billions of ultra-fine fibers with diameters of only 3–10 micrometers (significantly smaller than a human hair). These nano-fibers create a three-dimensional capillary structure, combined with an oleophilic (oil-attracting) and hydrophobic (water-repelling) surface treatment applied via advanced plasma technology – without the use of harmful silicone chemicals commonly found in lower-grade products.

Oil absorbent pads only absorb oil, not water

Key technical specifications (verified by Quatest 3 – October 2020):

- Oil-selective absorption, 100% water-repellent: Selectively absorbs hydrocarbons such as diesel oil (DO), fuel oil (FO), engine oil (15W40), hydraulic oil, metalworking fluids, gasoline A95/E5, organic solvents, and even vegetable oils. Water absorption rate after 30 minutes of contact ≤0.02 times pad weight (ASTM F726-12).

- Ultra-fast absorption speed: Reaches saturation in just 2–5 seconds with DO at 25°C – 3–5 times faster than conventional absorbent pads, thanks to strong capillary action and Van der Waals forces between nano-fibers and oil molecules.

- Superior absorption capacity: 14–18 times the pad’s own weight (e.g., P50 absorbs ≥2.3 liters of DO per pad). Zero drip retention after 30 minutes inverted hanging, even at temperatures up to 55°C.

- Exceptional mechanical strength: Tensile strength ≥48 N/5cm (dry), ≥30 N/5cm (saturated), elongation at break 55–72% without tearing or fiber shedding. Operating temperature range: –40°C to +120°C, suitable for harsh environments such as ship holds or high-temperature steel mills.

- Safety & sustainability: Non-flammable (flash point >380°C), non-toxic (MSDS-certified, non-irritating to skin), and reusable 3–5 times after centrifugal extraction (80–93% oil recovery, depending on oil type).

The product fully complies with TCVN 10488:2015 (Oil and chemical absorbent materials), ASTM F726-12 (Standard test method for sorbent performance), ISO 14001 (Environmental management), and is supplied with batch-specific CO-CQ. N-FIBER oil absorbent pad also meets the hazardous waste management requirements under Circular 02/2022/TT-BTNMT, facilitating environmental reporting for enterprises.

N-FIBER Oil Absorbent Pad Product Variants – Optimized Selection for Every Scenario

Based on application data from over 2,000 actual spill incidents, Bignanotech has developed four primary N-FIBER oil absorbent pad variants, each customized in thickness, size, and fiber density:

- N-FIBER P30 (30×30 cm, 3-5 mm thick, 23–27 g/pad): Ideal for minor daily incidents. Absorbs ≥0.85 liters DO, easily cut into smaller pieces for wiping drips under vehicles in automotive workshops or on CNC benches in cleanrooms. Packed 100 pads/carton.

- N-FIBER P40 (40×40 cm, 5 mm thick, 42–48 g/pad): The most popular variant, chosen by 80% of customers. Absorbs ≥1.2 liters/pad. Perfect for mechanical workshops, petroleum depots, and hydraulic oil cleanup on epoxy floors. Available in perforated version for easy tearing.

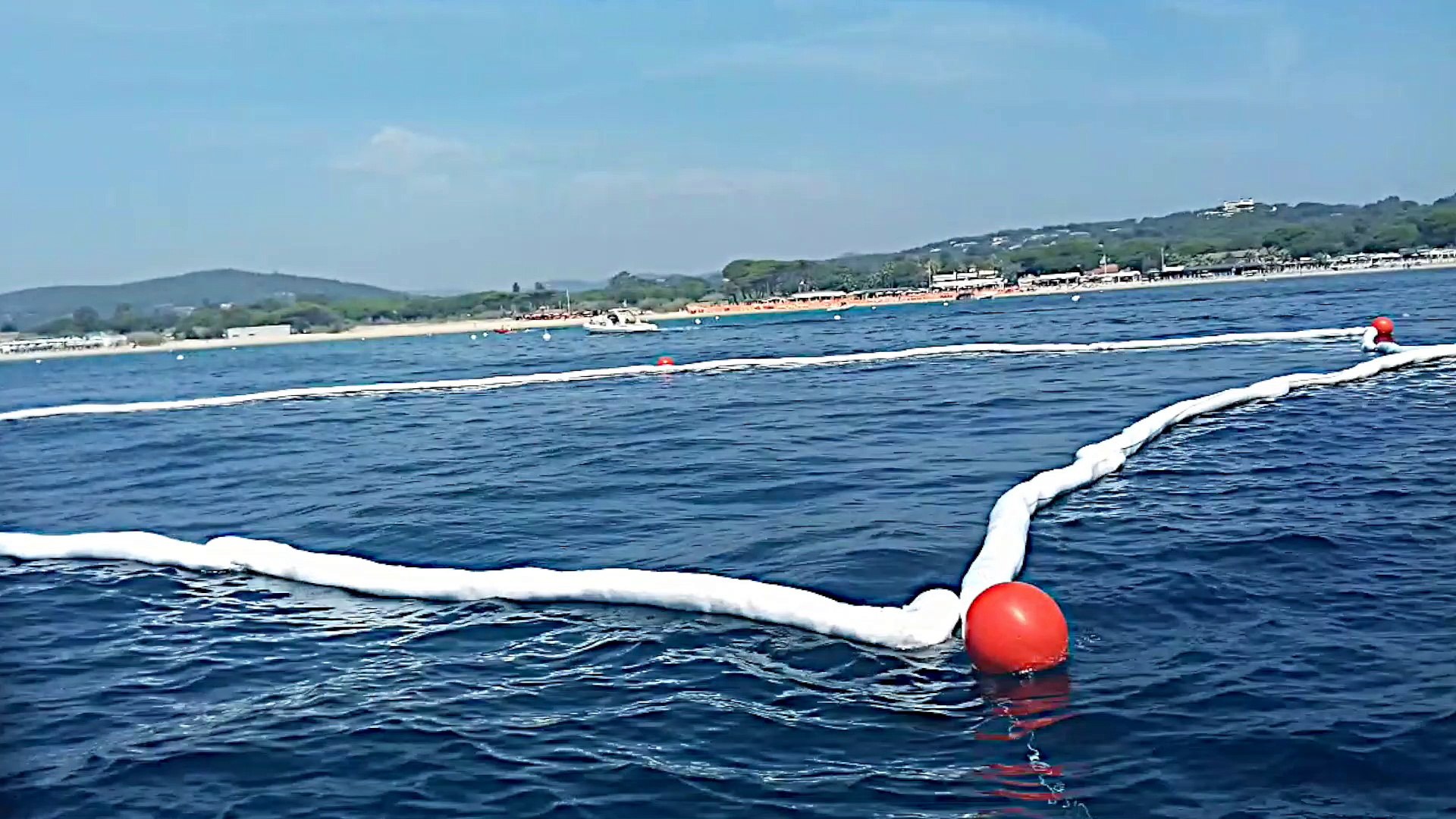

- N-FIBER P45 (40×50 cm, 5 mm thick, 65–75 g/pad): Designed for larger areas such as seaports and thermal power plants. Absorbs ≥1.7 liters with excellent buoyancy, commonly paired with N-Fiber oil absorbent boom containment booms for 5–10 liter spills.

- N-FIBER P50 (50×50 cm, 5 mm thick, 90–100 g/pad): Heavy-duty solution for major incidents on rivers, lakes, or ship holds. Absorbs ≥2.3 liters, featuring a high-density bottom layer for heavy FO under wave grade 2–3 conditions.

All variants are available with perforation, custom printing (company logo), or non-standard dimensions (minimum order 50 cartons), and are packaged in moisture-resistant cartons with a shelf life of up to 2 years when stored properly.

N-Fiber P45 – Heavy-duty solution for major oil spills on rivers

Real-World Applications – Detailed Case Studies from Major Partners

N-FIBER has been widely deployed with proven superior performance. Selected case studies (based on 2025 environmental audit reports):

- Samsung Display Vietnam (Thai Nguyen & Bac Ninh): P30/P40 used in Class 10,000 cleanrooms for robot lubrication oil wipe-down. Result: 25% reduction in maintenance downtime, zero secondary fiber contamination. Monthly consumption: 60–80 cartons, fully integrated into ISO 14001 procedures.

- Cat Lai & Hiep Phuoc Ports (Tan Cang Corporation): P45/P50 integrated into 100% of dockside Spill Kits. In an August 2025 FO spill of 25 liters, complete cleanup achieved in 2 minutes 12 seconds – 45% cost reduction compared to previous methods. Annual savings exceeding VND 500 million through reuse.

- Petrolimex Nha Be Depot: Combined with containment booms, response time reduced from 30 minutes to 5 minutes for tank leaks. November 2025 test: 91% DO recovery from 10-liter spill, residual water concentration <3 ppm (Oil Content Analyzer).

- Hoa Phat Dung Quat & Formosa Ha Tinh: P50 deployed for turbine oil at 45–50°C in blast furnace areas. 60% reduction in contamination risk, supporting quarterly reporting under Decree 08/2022/ND-CP.

Oil absorbent pads are fully equipped in oil spill kits at Petrolimex gas stations

These results are derived not only from internal data but also from direct client feedback and independent audits, demonstrating that N-FIBER reduces spill response costs by 40–50% while enhancing regulatory compliance.

Safe and Optimized Usage Guidelines

To maximize performance, Bignanotech recommends the following four-step protocol (aligned with OSHA 1910.120):

- Preparation & Assessment: Don full PPE (nitrile gloves, safety goggles, anti-slip boots). Identify oil type (light/heavy), spill area, and risks (surface water or floor). Prepare fine-mesh recovery nets (<5 mm) and 120-micron PE bags.

- Application: Spread pads to fully cover the oil slick (ratio: 1 P50 pad per 2–2.5 liters oil). On water: deploy gently from upwind side. Wait 5–15 seconds until pads turn dark (saturation). On floors: fold 4–8 layers and wipe from outer edge inward; avoid aggressive scrubbing.

- Recovery & Verification: Retrieve with recovery net or fold on floors. Verify residual oil <5 ppm using test paper. For reuse (clean oil only): centrifuge at 3000 rpm to recover 80–93% oil.

- Post-Use Disposal: Place in double PE bags, seal, and label as hazardous waste (code 19 02 08 per Circular 02/2022). Temporary storage <90 days, then transfer to licensed waste processor. Bignanotech can introduce certified partners upon request.

Note: In windy or wavy conditions, deploy containment booms first. Store at 15–25°C away from direct sunlight.

Why Choose Bignanotech? Comprehensive Commitment from a Domestic Manufacturer

As the first company in Vietnam to industrialize Meltblown technology at scale, Bignanotech offers distinct advantages:

- Nationwide delivery within 24–48 hours (Delivery from factory warehouse in Thai Binh).

- Free technical consultation and customized Spill Response Plan development.

- Free testing samples (5–10 pads of any variant).

- Customization options: logo printing, non-standard sizes for large orders.

- Superior after-sales: 1:1 replacement for manufacturing defects, periodic performance follow-up.

- Sustainability: 100% localized raw materials, 30% lower carbon footprint than imported equivalents.

We don’t just sell products – we contribute to a greener, safer industrial Vietnam.

Conclusion: Be Prepared – Act Today

Oil spills can happen at any moment, but with Bignanotech’s N-FIBER, you are fully equipped to respond effectively while protecting our precious natural resources. Contact us today for free consultation, testing samples, and exclusive November 2025 offers.

Hotline: 0879 808 080/ 094 386 7099/ 0868 939 595 (24/7 support)

Email: sales@bignanotech.com

Website: bignanotech.com.vn (Online sample request available)

Follow us: Facebook Bignanotech (Latest case studies & updates)

Youtube Bignanotech& Tiktok Bignanotech (updates videos about the latest case studies)

Together with Bignanotech, let’s spread nano-technology for a cleaner, greener future!

Bignanotech – Nano Technology for a Greener Tomorrow.