Industrial enterprises must be well-informed about industrial cleaning products and spill response solutions to promptly handle potential hazards to humans and the environment. One of the most significant concerns is dealing with oil and chemical spills during operations.

Using rags and scrap fabric is neither effective for thoroughly cleaning oil stains nor reusable for the spilled liquids. Instead, the market offers specialized oil absorbent materials that improve efficiency, save time, and reduce costs for handling oil and chemical spills.

Preventing and addressing issues caused by oil/chemical spills according to government regulations and laws helps ensure worker safety and environmental protection, while also avoiding hefty fines for violations.

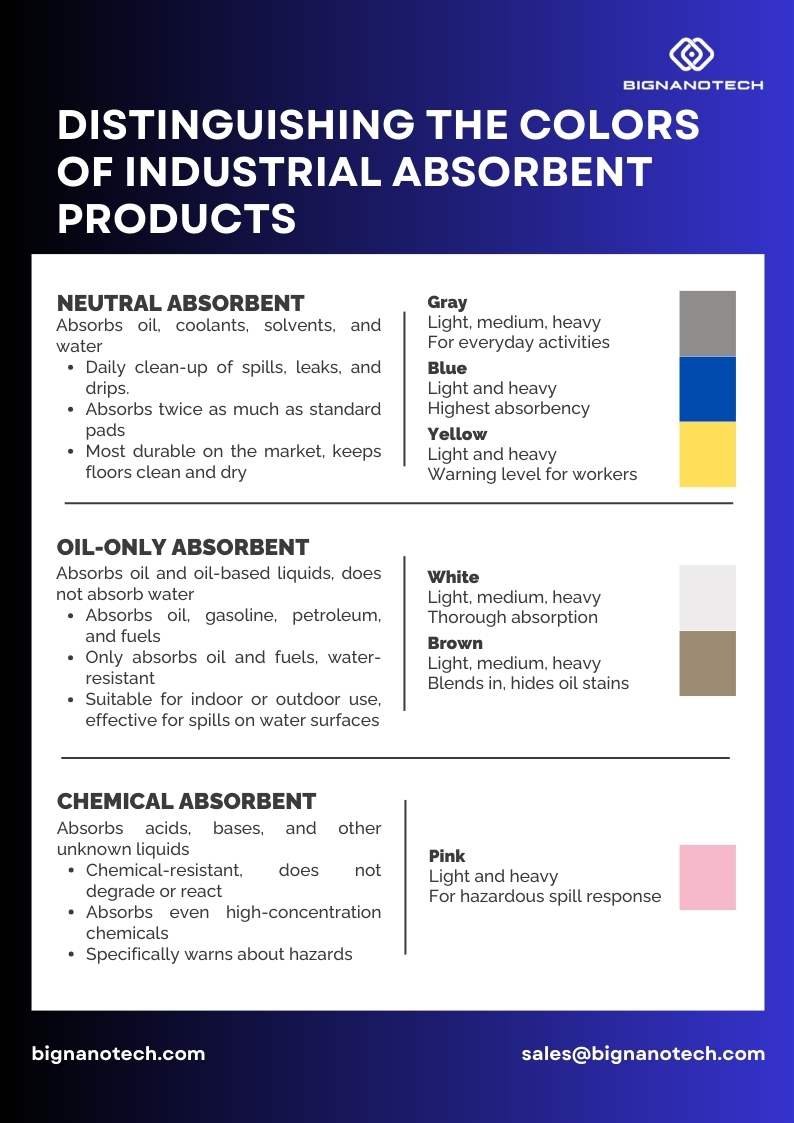

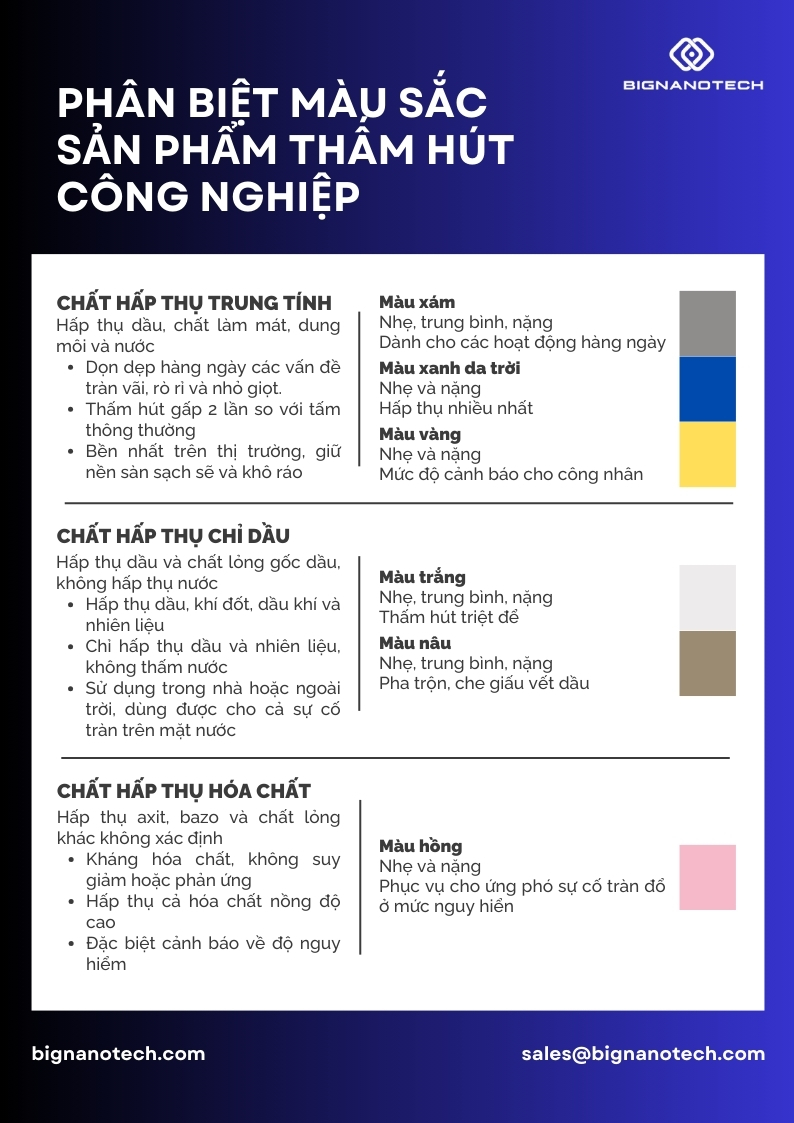

Globally, specialized oil absorbent products use different colors to indicate their applications. Let’s explore the differences between these colors and the functions of these products with BIGNANOTECH.

1. Gray, Blue, and Yellow: Neutral Absorbents/Universal Absorbents

Products in these colors are typically used for responding to and handling chemical-related incidents involving corrosive and highly volatile liquids. These chemicals are commonly used in modern industrial fields but are particularly hazardous in case of leaks or spills.

Strong solvents, coolants, and non-concentrated chemicals are effectively cleaned and contained by chemical absorbent pads in these colors, preventing further spills. These hazardous materials must be stored in specialized containers.

It is important to note that these products do not neutralize the chemicals they absorb and clean, so they remain dangerous if misused. Therefore, users must be equipped with appropriate safety gear when handling spills.

2. White, Brown: Oil Absorbents

These color-coded products, such as pads and booms, are used to absorb and clean up oil spills, especially useful for dealing with water or other liquids contaminated with oil. These products are made from hydrophobic materials or treated with hydrophobic chemicals, so they only absorb oil and completely repel water. Additionally, nano technology enhances their oil absorption capacity without releasing the absorbed oil.

White oil absorbent pads and booms, being hydrophobic, float on water to absorb and contain spilled oil, making them ideal for use in rivers, lakes, seas, wells, and tanks. Oil stains are easily visible on white products. Brown products, while less visible when soaked with oil, do not compromise on absorbency. The market primarily uses white oil absorbent pads, booms, and pillows for any industrial oil cleaning activities.

3. Pink: Hazardous Material Absorbents

For highly dangerous liquids and chemicals, pink absorbent products are typically used. These products are specially designed to absorb even the most toxic chemicals without degrading or reacting with the chemicals. It is crucial to wear protective gear and handle these chemicals with extreme care.

Where to Buy These Products?

There are many suppliers of these products in the market. However, some products lack clear origins and guaranteed quality. Some products are imported from major global brands like 3M and Spilfyter. These products ensure quality but come at a high cost due to additional taxes when imported to Vietnam.

Understanding these challenges, BIGNANOTECH, a leading manufacturer of industrial oil and chemical spill response products in Vietnam, has introduced N-FIBER, H-FIBER, and G-FIBER product lines. These lines provide high-quality products at reasonable prices. Produced with advanced nano technology exclusively from Japan, BIGNANOTECH is confident in satisfying customers, helping to clean the environment, and ensuring a safe and clean working environment.

For advice and solution proposals for industrial cleaning, please contact:

BIGNANOTECH Co., Ltd.

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com