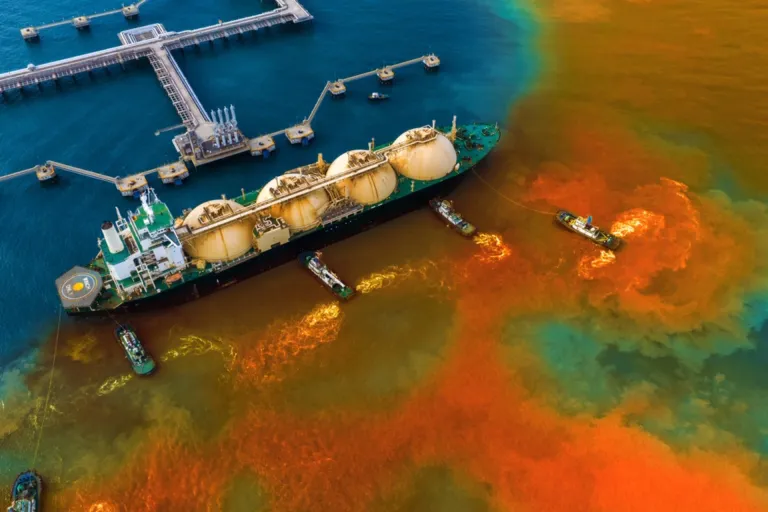

In today’s industrial landscape, where workplace safety and environmental protection are paramount, rapid and effective oil spill cleanup is a critical need for factories, fuel stations, laboratories, and seaports. N-FIBER oil absorbent pads from Bignanotech, powered by advanced Japanese nanotechnology, offer an optimal, eco-friendly solution to control oil spills instantly, minimizing risks and costs.

N-FIBER oil absorbent pads efficiently clean oil spills at a seaport, ensuring environmental safety

1. What Are Oil Absorbent Pads? Why Do Businesses Need Them?

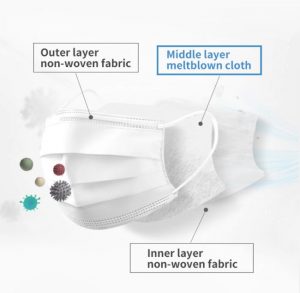

Definition of Oil absorbent pads:

Oil absorbent pads are specialized materials made from polypropylene, a synthetic polymer that is hydrophobic (repels water) and oleophilic (attracts oil). This unique ability to selectively absorb oil makes them highly effective for managing industrial oil spills, especially in environments with both oil and water, such as seaports, rivers, lakes, or wet production areas.

Why businesses need oil absorbent pads:

- Risk mitigation: Prevents environmental pollution, slips, and fire hazards.

- Regulatory compliance: Meets environmental standards like ISO 14001, OSHA (USA), and REACH (EU). Learn more about ISO 14001 standards.

- Reputation protection: Demonstrates commitment to sustainability and ESG (Environmental, Social, Governance) principles.

Real-world example: At Hai Phong Port, N-FIBER pads cleaned up 500 liters of spilled oil in just 30 minutes, saving 50% of the time compared to traditional methods.

Explore our range of oil absorbent products at Bignanotech Products.

2. Breakthrough Nanotechnology in N-FIBER Oil Absorbent Pads

N-FIBER oil absorbent pads, developed by Bignanotech in Vietnam, leverage cutting-edge Japanese nanotechnology. The ultra-fine polypropylene fibers with a nano-structured design maximize surface area, delivering:

- Superior absorption: Absorbs 15-20% more oil than standard products.

- Rapid cleanup: Absorbs oil in seconds.

- Water-repellent: Performs effectively in wet environments.

- Fire safety: Anti-static treatment ensures safe use in high-risk areas like fuel stations and chemical storage.

- Eco-friendly: Recyclable, supporting industrial waste management.

Discover more about Bignanotech’s nanotechnology!

3. Performance Evaluation of N-FIBER Oil Absorbent Pads

| Criteria | Performance |

|

Absorption Capacity |

P50 model absorbs up to 2.1 liters of oil per pad, 15-20% above average |

| Absorption Speed | Absorbs oil in seconds due to ultra-fine nano fibers |

| Safety | Anti-static, safe for high-risk fire hazard areas |

| Recyclability |

Easily sorted and recyclable, environmentally friendly |

N-FIBER exceeds standards set by the U.S. Environmental Protection Agency (EPA), OSHA, and ISO 9001, ensuring top-quality oil spill management.

4. Versatile Applications Across Industries

N-FIBER oil absorbent pads are highly versatile, suitable for various scenarios and environments:

- Manufacturing plants: Clean oil spills on floors, worktables, or maintenance areas.

- Fuel stations and auto garages: Manage oil leaks from vehicles or pumps.

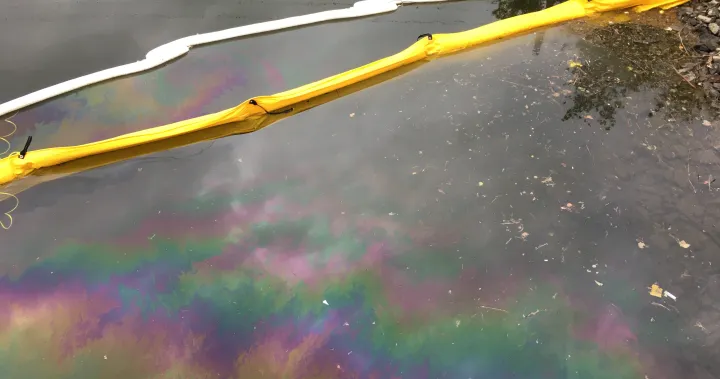

- Seaports and vessels: Remove oil slicks from water surfaces, minimizing pollution risks.

- Laboratories: Absorb oil-based solvents in sensitive settings.

- Emergency response: Included in Spill Kits for rapid reaction to incidents.

N-FIBER oil absorbent pads offer versatile solutions for oil spill cleanup across industries.

Have you faced an oil spill issue? Discover solutions at Bignanotech News.

5. Comparison with Other Solutions

| Criteria | N-FIBER Pads | Sand/Clay | Imported Products |

| Absorption Capacity | High, oil-only, no water absorption | Low, absorbs both oil and water | Medium to high |

| Cleanup Speed | Fast (seconds) | Slow | Moderate |

| Recyclability | Recyclable | Not recyclable | Limited recyclability |

| Cost | Affordable (locally produced) | Cheap but less effective | Expensive |

| Fire Safety | Anti-static | None | Varies |

Oil absorbent pad N-FIBER stands out for its high efficiency, affordability, and sustainability.

Bignanotech’s ISO 14001 certification ensures eco-friendly oil spill solutions.

6. Technical Specifications of N-FIBER Oil Absorbent Pads

| Model | Dimensions | Absorption Capacity | Packaging |

| P30 | 30cm x 30cm x 5mm | 1.2L/pad | 100 pads/box |

| P40 | 40cm x 40cm x 5mm | 1.6L/pad | 100 pads/box |

| P45 | 45cm x 45cm x 5mm | 1.8L/pad | 100 pads/box |

| P50 | 50cm x 50cm x 5mm | 2.1L/pad | 100 pads/box |

Note: Absorption capacity may vary depending on oil type and conditions.

7. Usage and Storage Guidelines

- Select the right model: Choose P30–P50 based on spill area and oil type.

- Deploy quickly: Place pads directly on the spill or create a containment barrier.

- Monitor and replace: Swap out saturated pads with new ones.

- Storage: Store in a dry place, away from direct sunlight.

- Disposal: Follow Vietnam’s hazardous waste regulations (Circular 02/2022/TT-BTNMT).

Request a quote today at Bignanotech Contact!

8. Bignanotech – Your Trusted Oil Spill Solution Provider

Bignanotech Co., Ltd. is a pioneer in nanotechnology research and application in Vietnam, delivering modern, safe, and cost-effective oil spill cleanup solutions for domestic and international clients.

Contact Information:

- Address: Tower A, The Manor, Me Tri, My Dinh 1, Nam Tu Liem District, Hanoi, Vietnam

- Hotline: (+84) 879 808 080 | (+84) 868 939 595

- Email: sales@bignanotech.com

- Website: https://bignanotech.com/

Explore our full range of oil absorbent products at Bignanotech Products.

N-FIBER oil absorbent pads provide a smart solution for businesses in Vietnam to address oil spills quickly, safely, and sustainably. Powered by Japanese nanotechnology and a commitment to environmental protection, Bignanotech is your ideal partner for effective oil spill management.

Contact us today via Bignanotech Contact for expert advice and the best pricing!