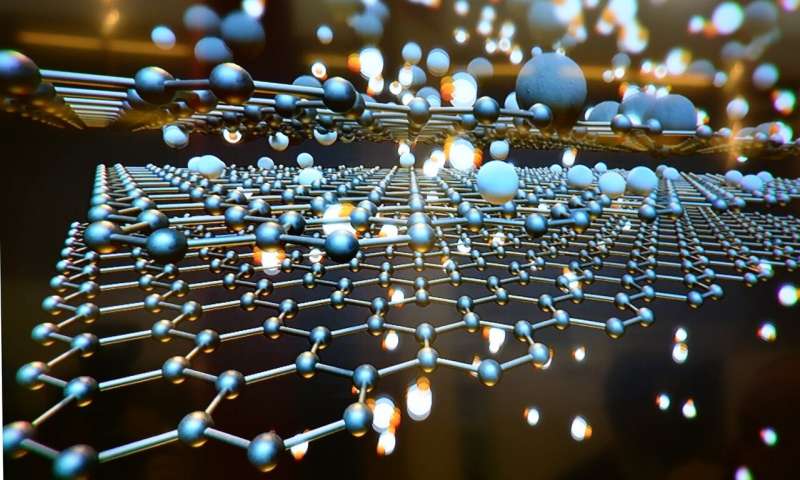

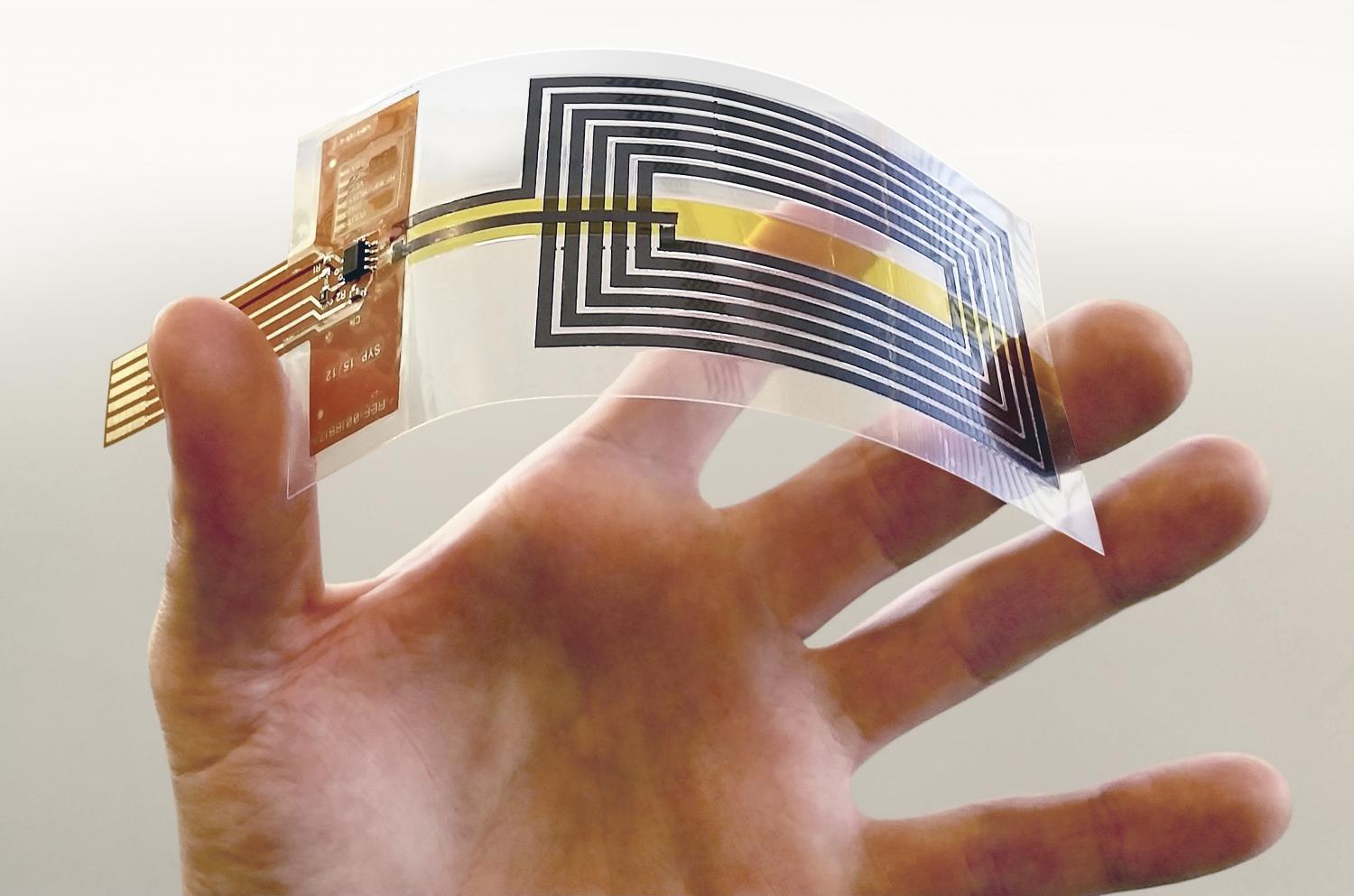

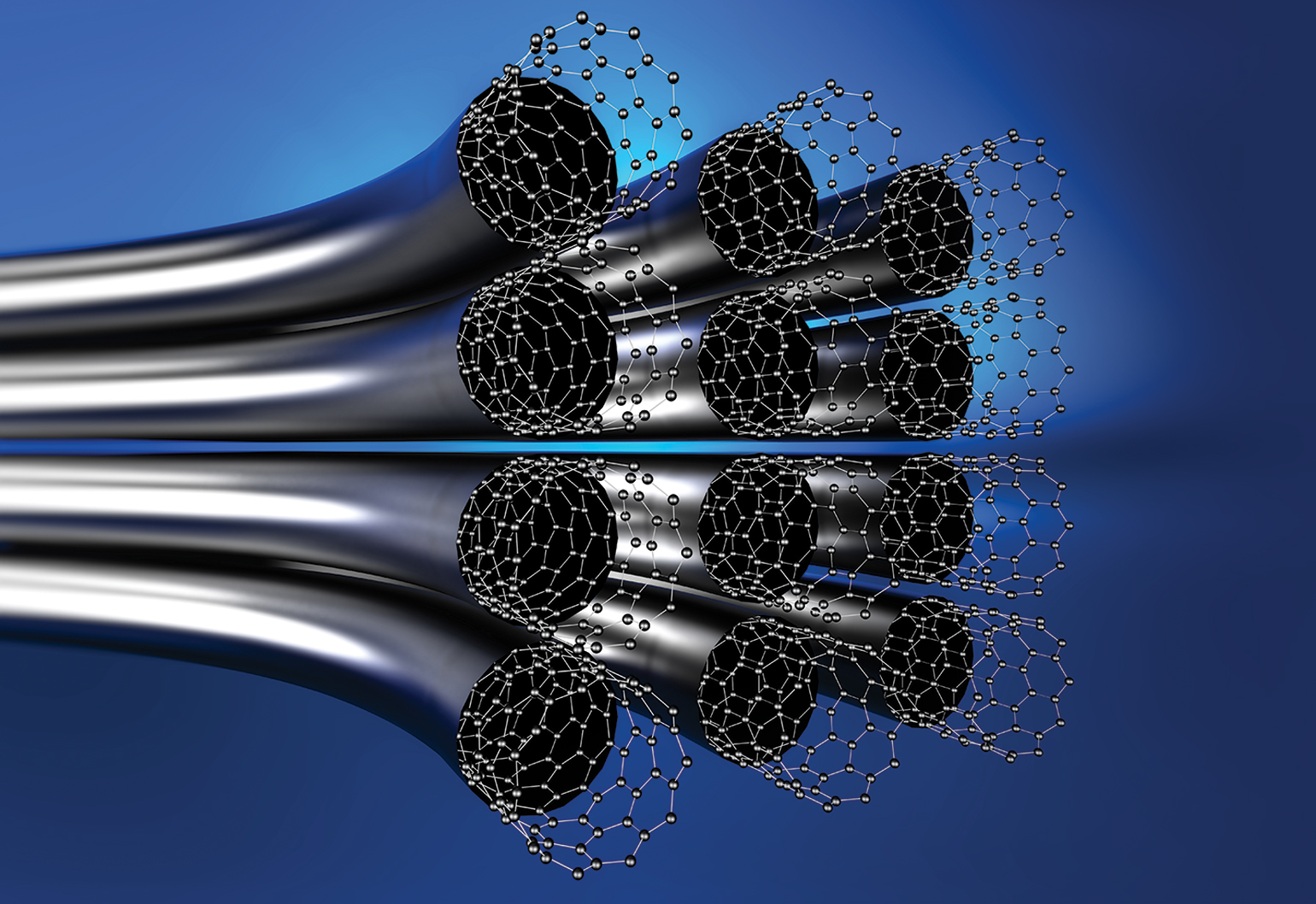

Graphene plays an important role in the production of biosensors – sensing devices based on interactions between biomolecules and graphene. The combination of graphene’s exceptional properties and reactivity with biomolecules opens up many important applications in the medical, environmental and bioanalytical fields.

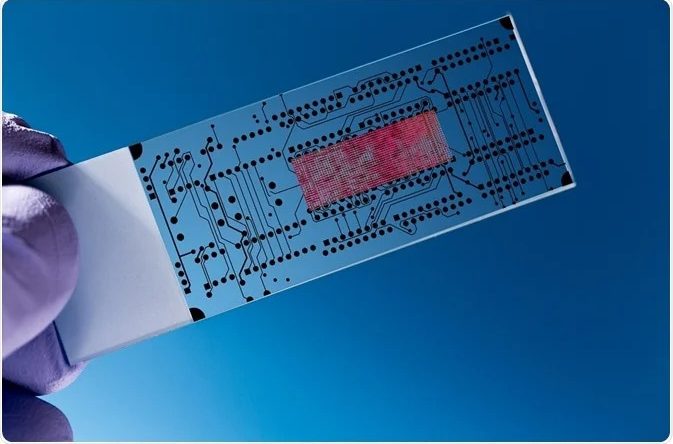

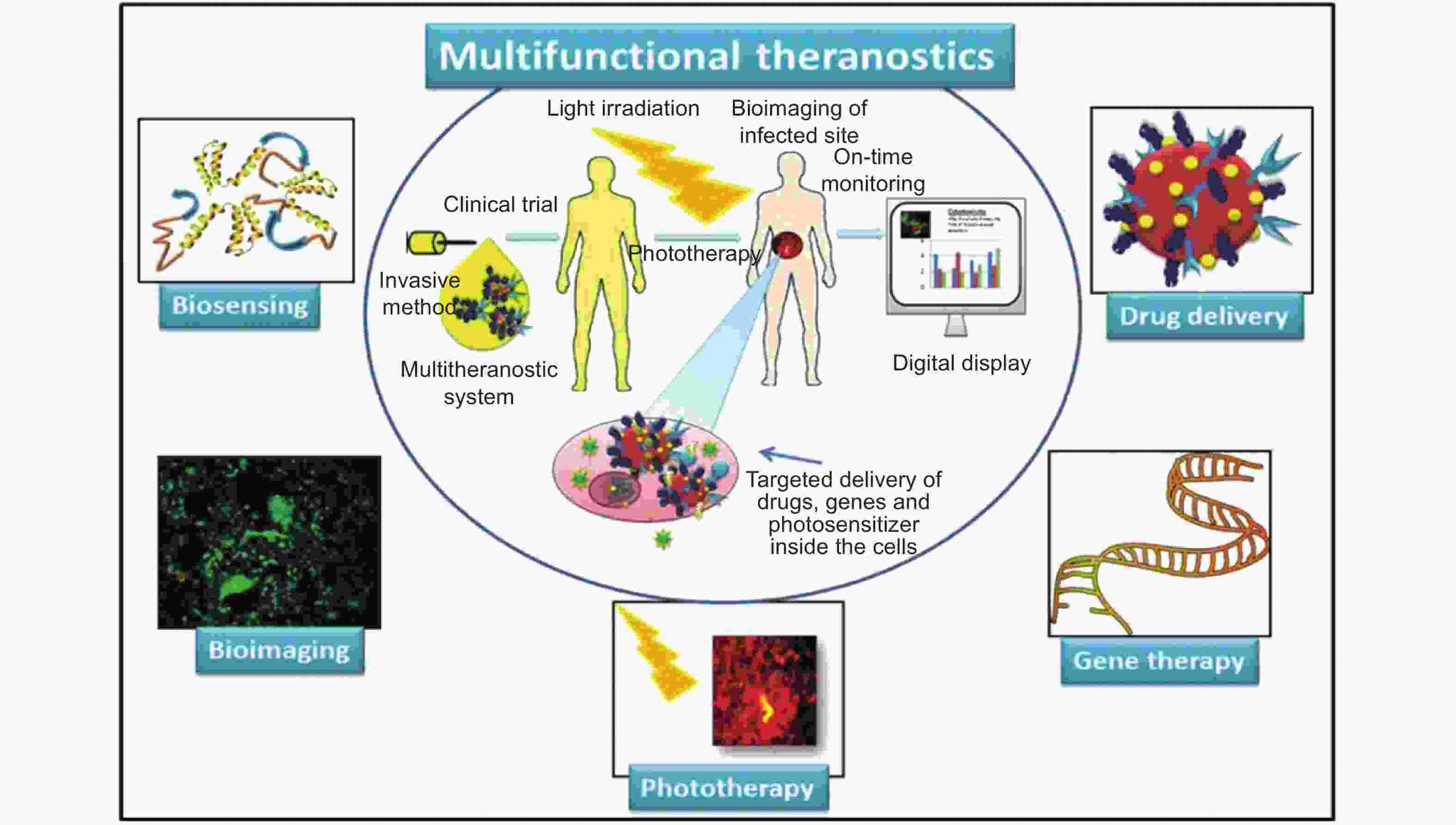

- Disease detection and warning: Graphene is used in the production of biosensors capable of detecting and warning diseases, bacteria, viruses and other pathogens. The interaction between biomolecules and graphene produces measurable electrical resistance or current changes, thereby determining the current state and levels of those substances.

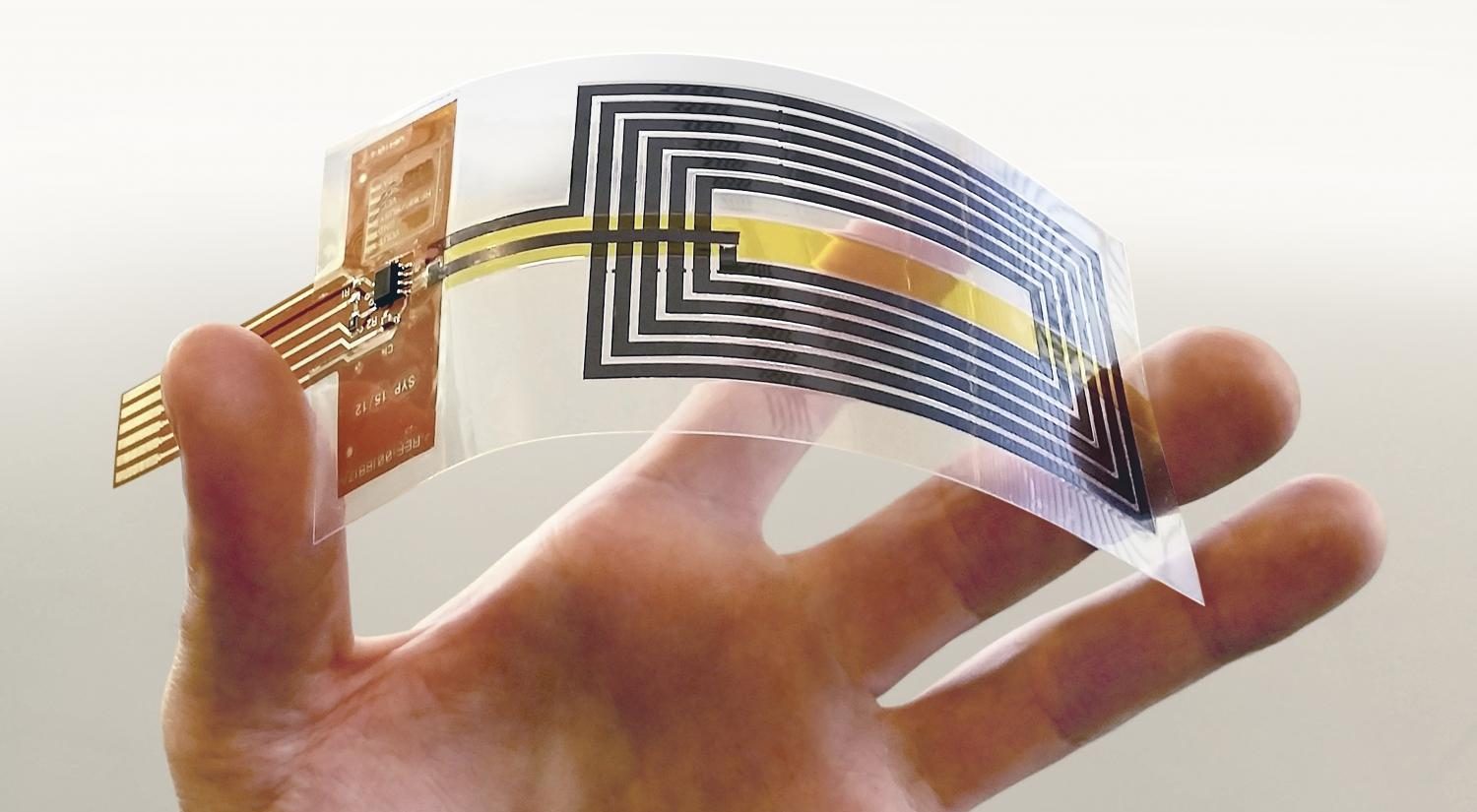

- Personal Health Monitoring: Graphene biosensors are also used to monitor personal health and physiological indicators such as blood glucose, skin pH, heart rate and other blood substances. These parameters can be monitored in real time and provide useful information for health monitoring and disease prevention.

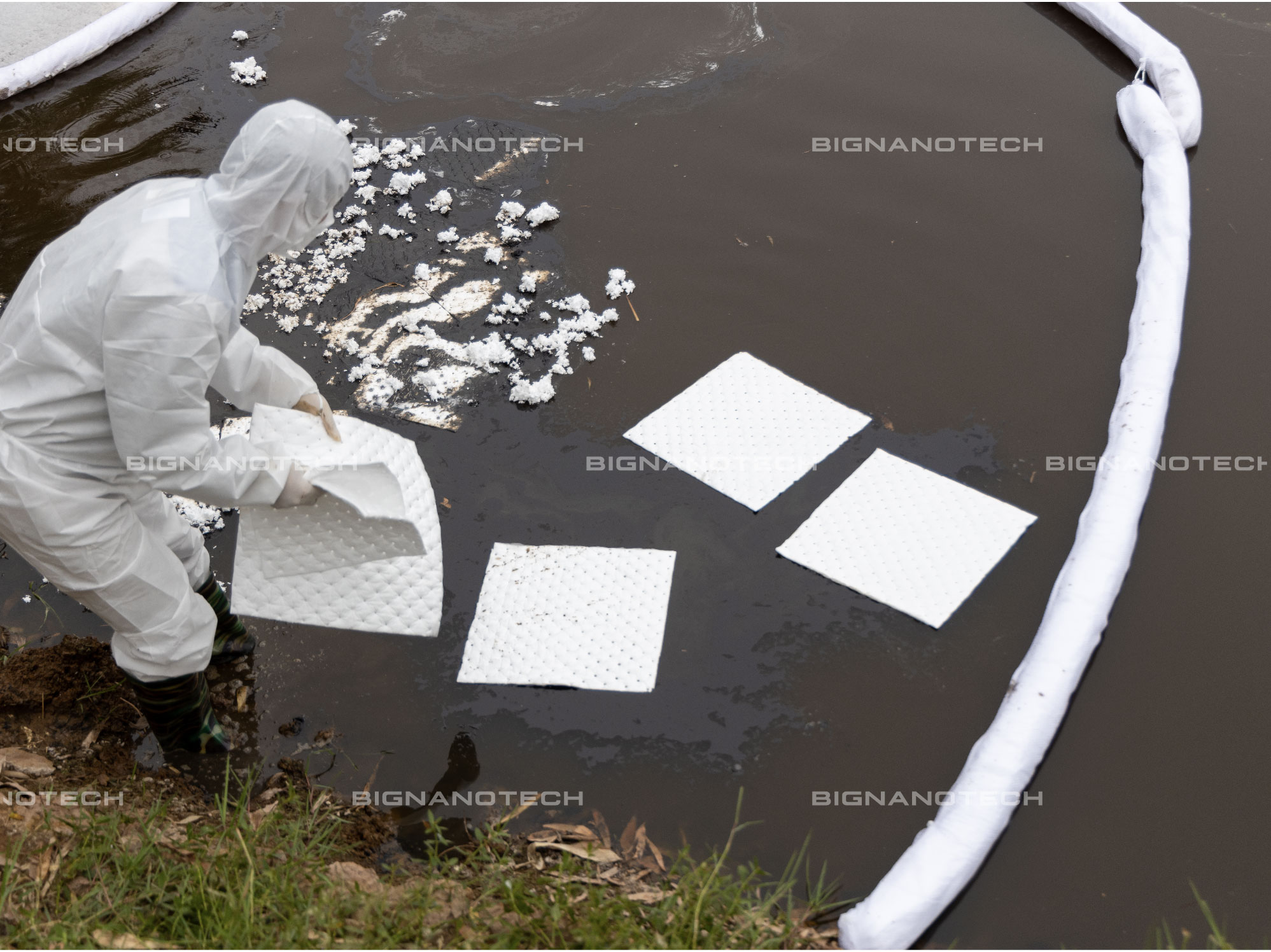

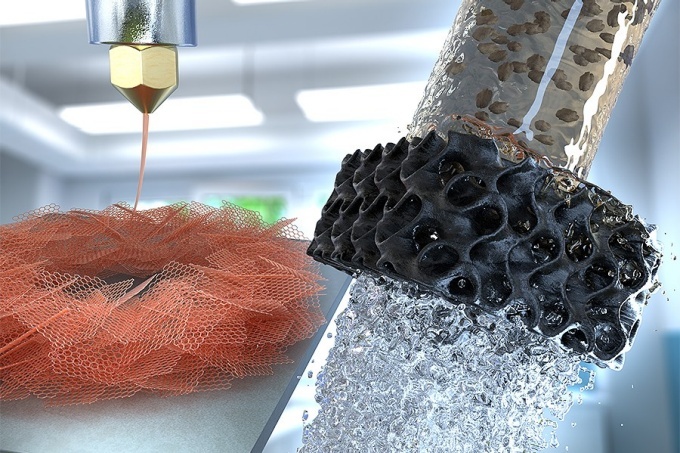

- Food and Environmental Analysis: Graphene in biosensors is also used in environmental analysis and food quality control. Biosensors are capable of detecting and measuring pollutants and toxic substances in water, air and food environments, helping to ensure safety and quality in products and the environment.

- Medical and biological research: Graphene biosensors play an important role in medical and biological research. They are used to study and measure biological processes, evaluate the impact of pharmaceuticals and biological partners, and thereby improve will and development in the field.

- Investigation of drug resistance and antibiotic resistance: Graphene biosensor is capable of detecting the existence of resistant micro-drugs and antibiotic substances. This is important in the prevention and treatment of infections and diseases, helping to choose the right antibiotic and minimizing unnecessary use.

- Water and Atmospheric Quality Testing: Using graphene in biosensors allows for quick and accurate testing of water and air quality. These biosensors can detect pollutants and contaminants in water and air, helping to effectively assess and manage the environment.

- Food production and agriculture: Graphene in biosensors also has applications in food production and agriculture. Biosensors are capable of detecting and measuring contaminants in food and soil, helping to ensure safety and quality in food products and protect the agricultural environment.

The development of graphene in the production of biosensors promises to open up hidden possibilities and new opportunities in the fight against disease, health monitoring and environmental protection.

To discuss and cooperate in developing this technology, please contact us

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com