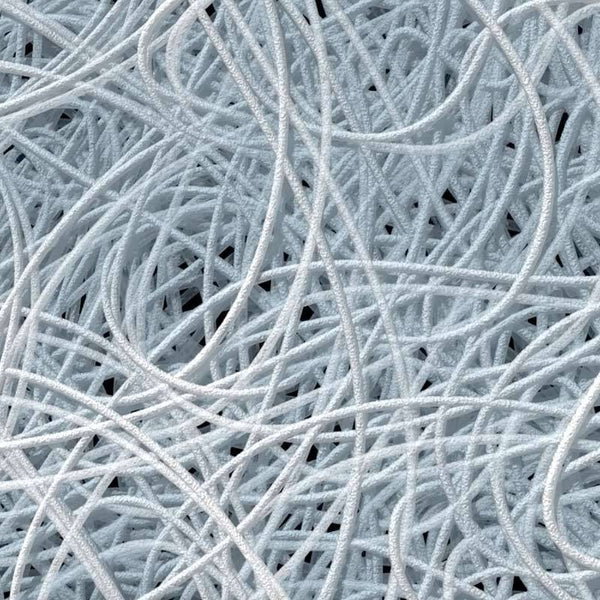

Utilizing unique technology, we generate a substantial amount of intricately woven nano-sized fibers ranging from 50 to 400 nm, achieving outstanding performance for features such as super-absorbency, mold resistance, and high thermal insulation.

With advanced manufacturing technology, we can produce in large quantities at low costs while ensuring high-quality standards for our products.

Boasting 1.5 times the thermal insulation performance of glass wool, nearly equivalent to phenolic foam, and at a cost less than half (thermal insulation performance comparable to a thickness of about 70%). It maintains insulation effectiveness even with the addition of 50% water weight.

Soft and elastic material allows for easy gap filling, reducing post-construction gaps and preventing water condensation inside. This makes nanofiber suitable for thermal insulation in construction projects and transportation vehicles.

Impervious to water, with a water and moisture absorption rate of 0%. Even when installed in areas with condensed moisture, the thermal insulation performance of nano fibers remains unaffected.

No mold growth, even when installed in places with high condensation.

Non-flammable, does not catch fire even in close proximity to heat sources.

Industrial and Construction: Nano Fiber serves as material for soundproof walls, thermal insulation, and is utilized across various industrial sectors. It can be easily applied in a short period without creating any gaps, even in uneven areas such as pipes, electrical wires, and narrow, complex spaces that were previously only addressed using glass wool.

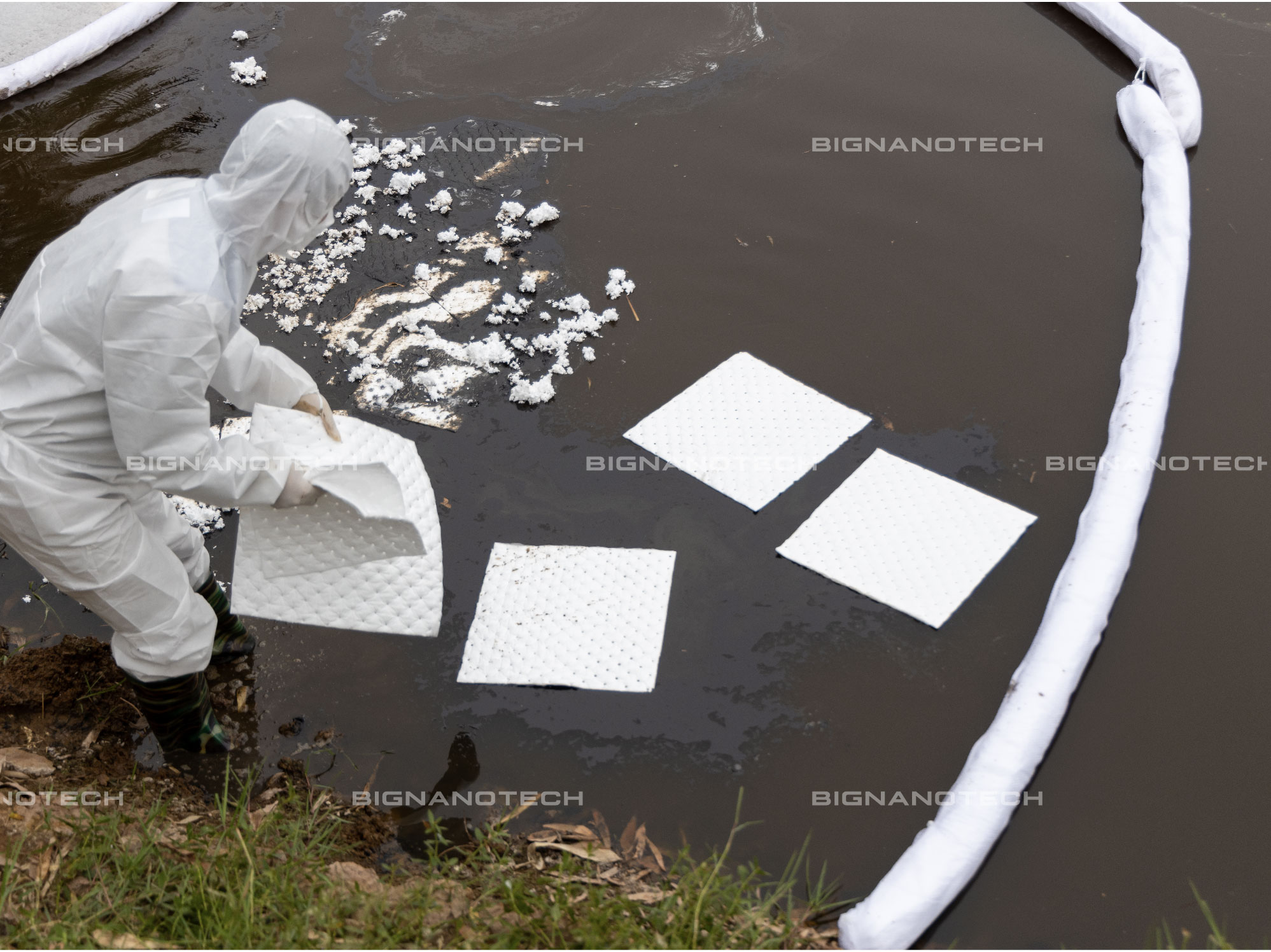

Environment: Acting as an oil and chemical absorbent material, it is employed in responding to and managing incidents of oil/chemical spills that cause environmental pollution.

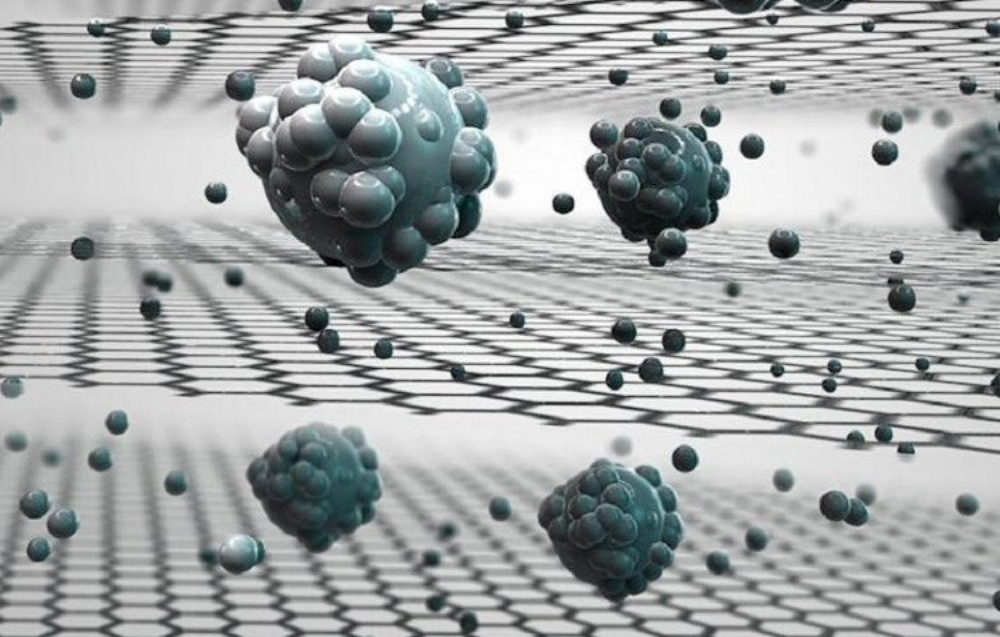

Water Filtration: Nano fibers can effectively filter industrial oils and chemicals with high concentrations, being water-resistant. They can be used in water filtration systems to remove oil/chemicals/pollutants from water.

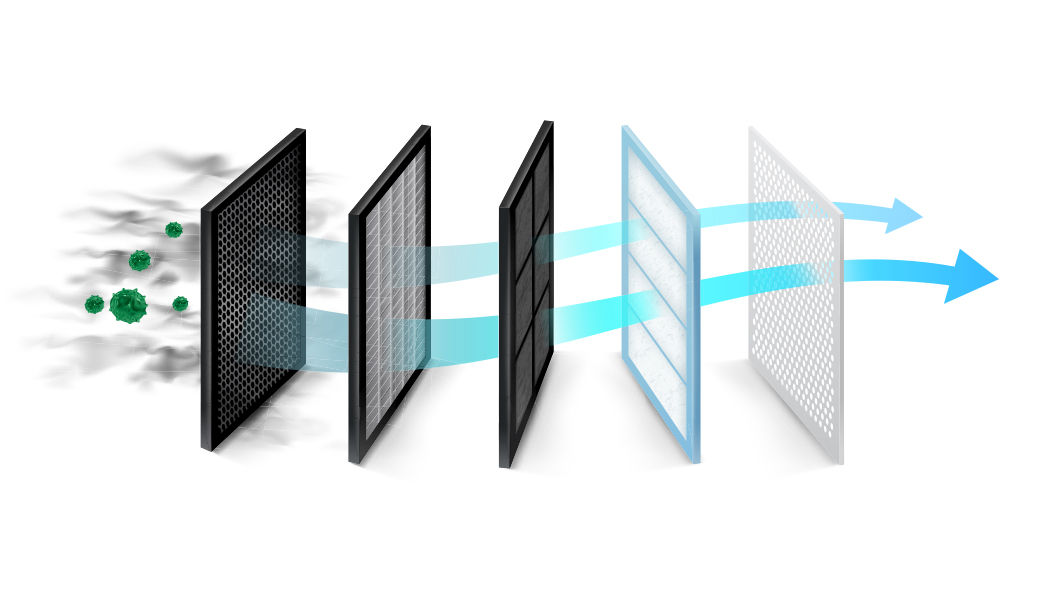

Air Purification: They can be used to eliminate toxic gases, fine dust, and bacteria in air filtration systems, masks, and medical applications.

Sports and Fashion: Nano fibers find application in creating water-resistant and heat-absorbing sports and fashion products.

Life Products: Used as a material for high-quality lifestyle products made from ultra-fine fibers.

BIGNANOTECH has collaborated with leading experts in Japan to develop exclusive nanofiber production technology. Using high-quality resin particles, Big Nano Tech has successfully manufactured large-scale ultra-fine fiber sheets reaching nano dimensions, creating products with a broad range of applications and superior functionality compared to traditional technologies.

We have received your request for sample.

Our research specialist will contact you soon.