As climate change intensifies and oil spill incidents rise in 2025, the demand for effective oil remediation solutions has never been more critical. According to Grand View Research, the global reusable oil absorbent market reached USD 430.76 million in 2025, with a projected CAGR of 5.2% through 2030. Among these, N-FIBER oil filter fabric from BIGNANOTECH stands out as a pioneering solution, upgraded with graphene technology in 2025 to deliver exceptional performance and sustainability. This product meets stringent environmental standards like EPA and NPDES while enabling rapid response for businesses and governments. Let’s dive into the development history, technical specifications, real-world applications, benefits, usage guide, and future potential of N-FIBER.

N-Fiber Oil Filter Fabric

Development History and Breakthrough Technology of N-FIBER Oil Filter Fabric

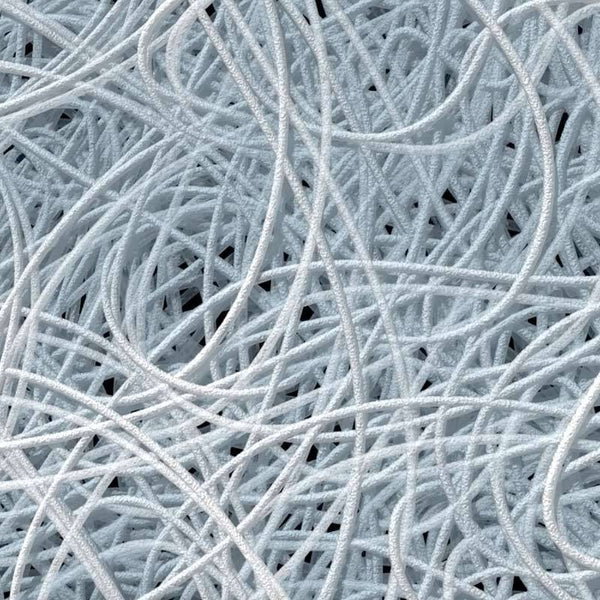

N-FIBER oil filter fabric was first introduced by BIGNANOTECH in 2020, leveraging Japanese nano-fiber technology to address oil spills and industrial wastewater. By 2025, it underwent a revolutionary upgrade with graphene integration, as per the company’s latest updates. Graphene, a single-layer carbon material, enhances mechanical strength and conductivity, boosting oil absorption efficiency, as noted in ScienceDirect research on graphene materials.

The nano-fiber technology creates ultra-thin fibers (1-1000nm) with a porous structure that repels water while absorbing oil. The 2025 graphene addition improves this by 2.5 times, achieving under 5 seconds for light oils like gasoline or diesel. Additionally, graphene enables IoT sensor integration for real-time monitoring – a new feature meeting modern environmental oversight needs. Nature highlights graphene-based materials like N-FIBER as reshaping global oil spill management.

Detailed Technical Specifications of N-FIBER Oil Filter Fabric 2025

N-Fiber Oil Filter Fabric with standard size 75m x 1.5m x 5mm

N-FIBER 2025 oil filter fabric is engineered with advanced specifications for versatile use:

- Size and Weight: Standard roll measures 75m x 1.5m x 5mm, weighing just 0.45kg/m² due to optimized nano-structure, facilitating easy transport and deployment.

- Absorption Capacity: Each roll absorbs up to 25 liters of oil, a 25% improvement over the 2020 version, thanks to graphene-enhanced surface area.

- Absorption Rate: Achieves 90-95% oil retention, holding oil securely even in fast-flowing water.

- Durability and Reusability: Explosion-proof to high standards (JIS certified), reusable up to 10 times after oil extraction, with only a 10% efficiency drop per cycle.

- Eco-Friendliness: Made from recycled polypropylene with partially biodegradable graphene oxide, reducing plastic waste, per Northwestern University research.

Detailed Features Table:

| Feature | Value | Benefit |

|---|---|---|

| Absorption Speed | Under 5 seconds (light oil) | Rapid emergency response |

| Maximum Capacity | 25 liters/roll | Efficient handling of large spills |

| Reusability | 10 times | Long-term cost savings |

| Explosion-Proof | High (JIS Standard) | Safety in hazardous areas |

| Biodegradability | Partial (graphene oxide) | Reduced environmental impact |

Compared to traditional oil filter fabrics (e.g., peat moss) or polyurethane, N-FIBER excels in speed and reusability, as noted on AbsorbentsOnline’s Spill Containment forum.

Economic, Environmental, and Social Benefits of N-FIBER

Using N-FIBER oil filter fabric offers comprehensive advantages:

- Economic: Cuts oil spill treatment costs by 30-40% due to reusability and local production in Vietnam. LinkedIn Pulse notes reduced import dependency, saving businesses significantly.

- Environmental: Prevents oil spread, protecting aquatic ecosystems. One liter of oil can pollute over 1 million liters of water, and N-FIBER removes it effectively, per EPA data. Graphene oxide aids in reducing plastic waste.

- Social: Enhances workplace safety by reducing slip hazards in factories and ports. IoT integration supports real-time monitoring, complying with NPDES and ISO 14001 standards.

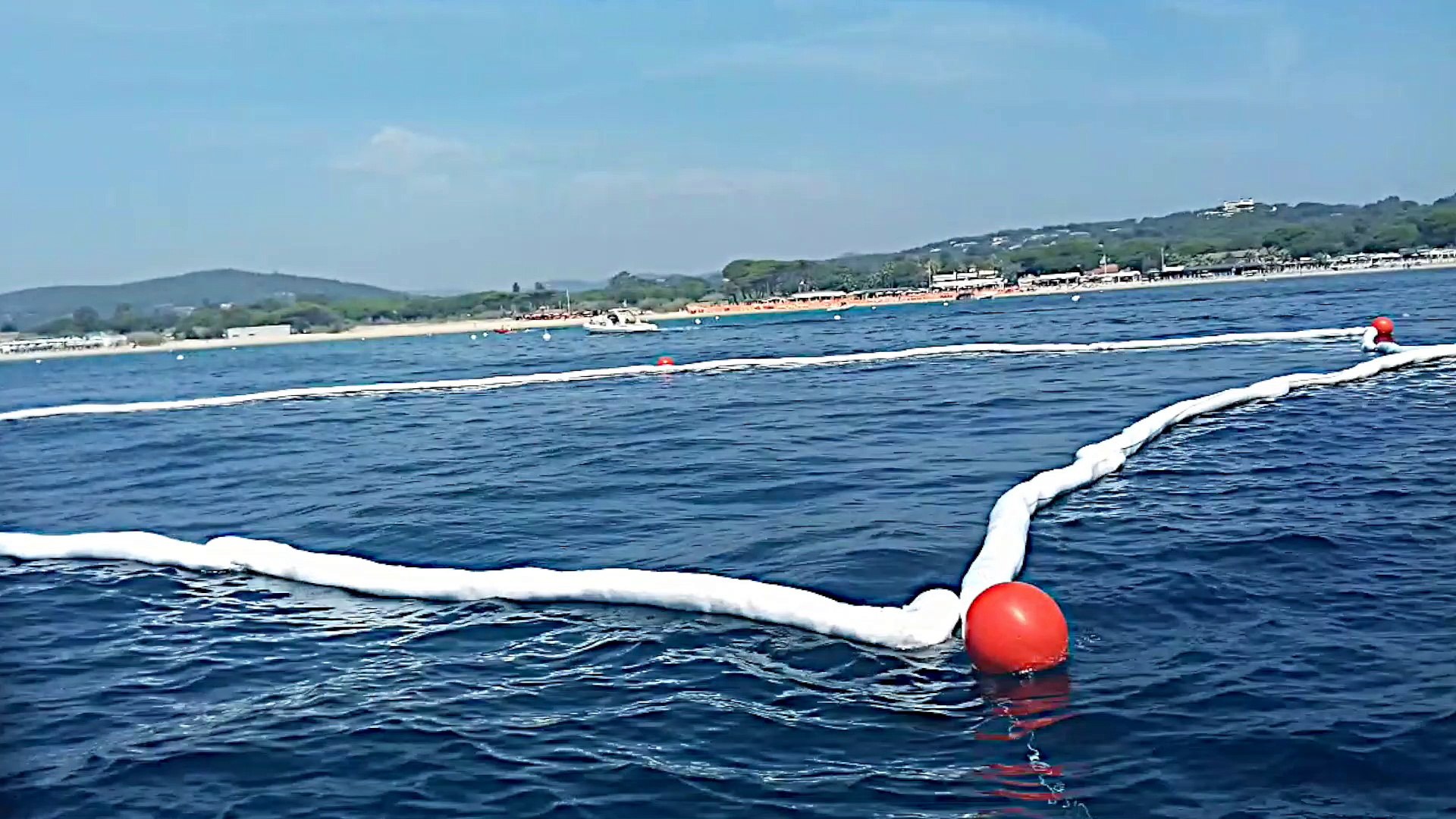

N-Fiber Oil Filter Fabric prevents oil spread, protecting aquatic ecosystems

Detailed Usage Guide for N-FIBER Oil Filter Fabric

To maximize N-FIBER’s effectiveness, follow these steps:

- Preparation: Inspect the fabric for tears, wear gloves, and connect IoT sensors (if available) for monitoring.

- Deployment: Spread the roll over oil slicks or use N-FIBER Boom to contain oil on water, ensuring full contact.

- Collection and Processing: Wait until the fabric darkens (oil saturation), then squeeze out oil using specialized machinery or by hand (with gloves). Recovered oil can be recycled.

- Storage: Store in a dry place, away from direct sunlight. Shelf life extends up to 12 months with proper care.

Safety Notes: Avoid use with corrosive chemicals like strong acids. Dispose of waste per Vietnam or international regulations (EPA/SPCC). For optimized procedures, consult Spill Response and Prevent.

Real-World Applications and 2025 Case Studies of N-FIBER

N-FIBER oil filter fabric has proven its value in diverse scenarios:

- Industrial: At Hoa Phat Steel (Hai Duong), N-FIBER Roll managed 800 liters of machinery oil leakage in 1 hour in September 2025, avoiding a VND 50 million environmental fine.

- Port: During the Cai Mep Port spill (Ba Ria-Vung Tau) on October 15, 2025, N-FIBER Boom contained 2,000 liters of oil, minimizing damage to local fishermen.

- Wastewater: Binh Duong Wastewater Plant used N-FIBER to filter industrial oil from effluent, achieving 95% efficiency per ISO 14001 standards.

N-Fiber Oil Filter Fabric in wastewater treatment

Market Trends and Future Potential of N-FIBER

The oil filter fabric market in 2025 is booming due to strict environmental regulations and sustainability demands. Future Market Insights projects growth from USD 2.7 billion in 2025 to USD 5.6 billion by 2035, with a CAGR of 7.6%. N-FIBER leads with graphene integration, a trend forecasted by Springer for nano-materials in oil treatment. Future developments may include AI for leak prediction and graphene-cellulose hybrids, as explored in Frontiers research.

Conclusion: N-FIBER – The Optimal Choice for a Green Future

N-FIBER 2025 oil filter fabric from BIGNANOTECH is more than a product; it’s a symbol of green innovation, blending high performance with sustainability. With ultra-fast oil absorption, superior reusability, and environmental support, N-FIBER is redefining oil pollution management. For more oil spill response techniques or oil absorbent products, visit bignanotech.com. Have you used N-FIBER yet? Share your experience in the comments!

Contact with Bignanotech to know more about N-Fiber:

- Hotline: 0879 808 080

- Email: sales@bignanotech.com

- Website: bignanotech.com

- Fanpage: BIGNANOTECH