WHAT IS AN ANTIMICROBIAL FILTER PAPER? APPLICATIONS IN FACE MASK PRODUCTION

A standard face mask must be capable of filtering dust and preventing harmful pathogens such as viruses and bacteria. So, what sets a regular mask apart from one that protects against disease-causing agents? The key lies in the inner antimicrobial fabric or filter paper. In this article, Bignanotech will walk you through everything you need to know about antimicrobial filter paper—a critical material in the production of high-efficiency face masks.

1. What is antimicrobial filter paper?

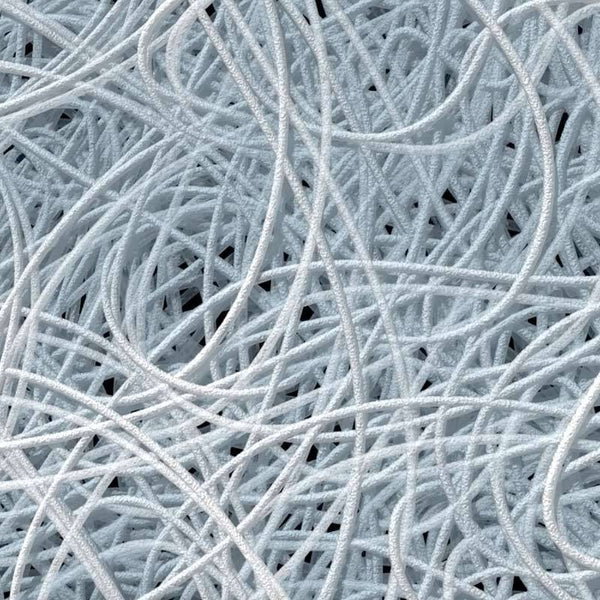

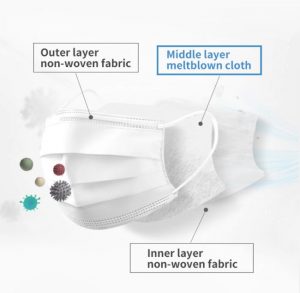

Antimicrobial filter paper is a specialized filtration material made from polypropylene (PP) fibers using the meltblown spinning technique. The polymer is melted, extruded through fine nozzles, and blown by high-pressure hot air to form ultra-fine fibers. These fibers are then collected into a nonwoven web that effectively blocks airborne particles, dust, bacteria, and viruses—even those of microscopic size.

This advanced filtration medium is key to ensuring face masks meet protective health standards.

2. Quality assessment criteria for antimicrobial filter paper

The quality of antimicrobial filter paper is commonly measured by its BFE (Bacterial Filtration Efficiency). BFE evaluates the material’s effectiveness in blocking bacteria by analyzing bacterial concentrations before and after passing through the filter layer.

A higher BFE percentage means better performance. Medical-grade antimicrobial filter papers typically achieve a BFE of 95% or higher—ensuring reliable protection in surgical and healthcare environments.

3. Applications of antimicrobial filter paper in healthcare and safety

Antimicrobial filter paper plays a crucial role in the medical industry. It is commonly used as the middle filtration layer in:

- Surgical face masks

- Medical face masks

- Respiratory masks for hospitals and clinics

Besides protecting against bacteria and airborne contaminants, some advanced antimicrobial papers also provide UV protection, making them ideal for a wide range of protective gear.

4. How to choose the right antimicrobial filter paper for face mask manufacturing

Selecting the right antimicrobial paper depends on the application and regulatory requirements. For medical mask production, the filter paper should have a minimum BFE of 95%.

When sourcing filter materials, manufacturers should prioritize certified suppliers with proven quality standards.

Why choose Bignanotech?

Bignanotech is a trusted manufacturer and distributor of antimicrobial filter paper in Vietnam. Our products are developed using high-grade raw materials and cutting-edge Japanese meltblown technology. We provide:

- High BFE antimicrobial filter paper

- Competitive pricing for bulk orders

- Fast delivery and expert consultation

- Certificates from Korean and Japanese partners

As global demand for protective masks continues to grow, Bignanotech is your reliable partner in ensuring quality, safety, and efficiency.

Contact us for antimicrobial filter paper supply: BIG NANO TECHNOLOGY CO., LTD.

Representative Office: Tower A, The Manor, Me Tri Street, My Dinh 1 Ward, Nam Tu Liem District, Hanoi, Vietnam

Hotline: (+84) 0868939595

Email: sale@bignanotech.com.vn

Website: http://bignanotech.com.vn/