In research labs, chemical production and storage companies, factories using chemicals in production, and similar settings, handling chemical spills and leaks is an essential part of production and operation processes. However, chemicals can pose significant health and environmental risks if not handled properly. Therefore, choosing the optimal and safe method for cleaning or responding to chemical spill incidents is crucial. One of the important and useful tools in controlling and preventing chemical spill incidents is the chemical absorbent boom.

1. What is a Chemical Absorbent Boom?

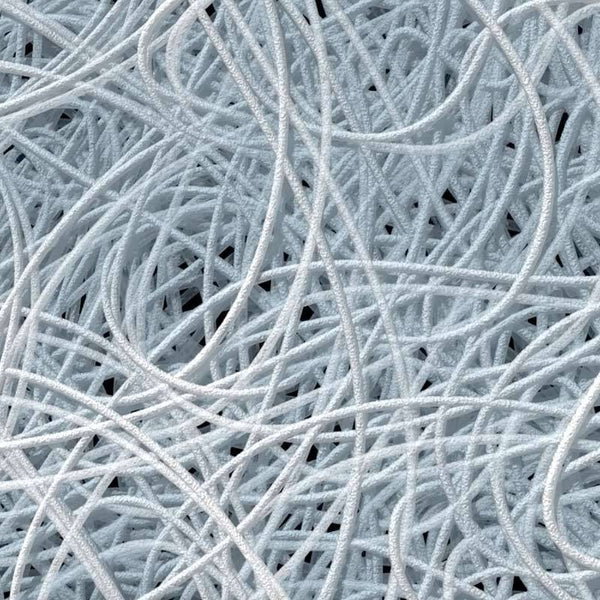

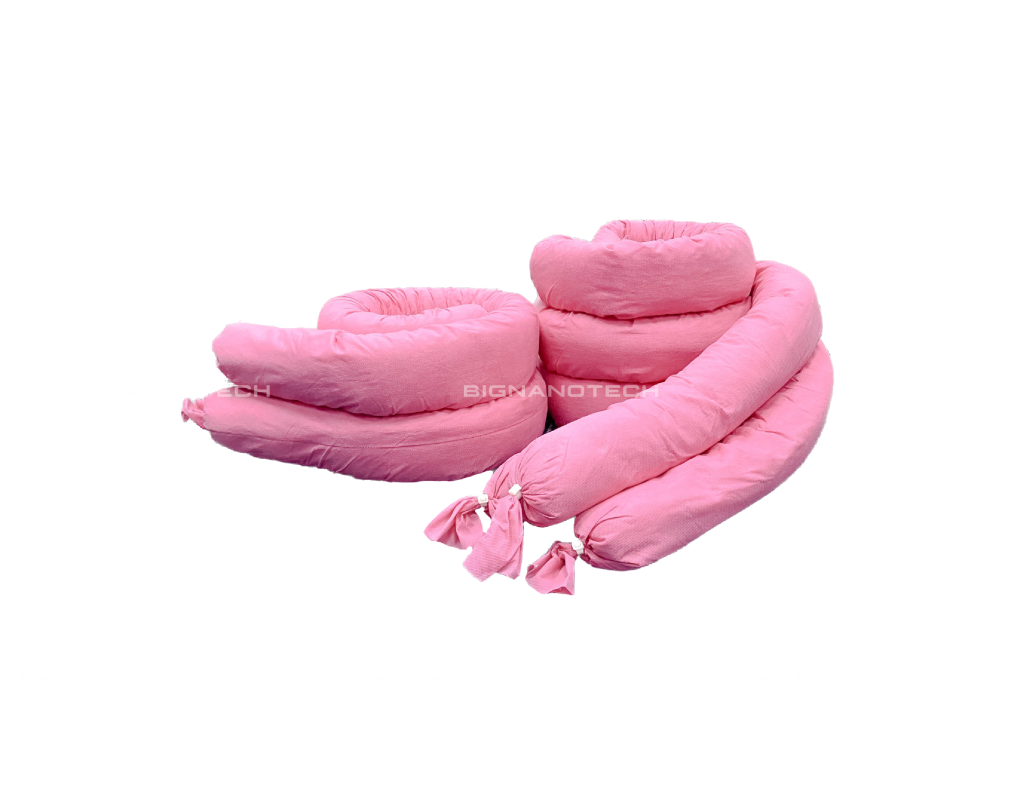

A chemical absorbent boom is a specially designed device to absorb and prevent the spread of liquid chemicals. They are usually made from high absorbency materials and can withstand the impact of strong chemicals. Due to their flexibility and efficiency, chemical absorbent booms are an ideal solution for dealing with unexpected spill situations.

2. Benefits of Chemical Absorbent Booms

- Fast Absorption Rate: Chemical absorbent booms can quickly absorb liquid chemicals, minimizing the spread and damage to humans and the environment. This is particularly important in emergency situations where every second counts and the surrounding areas are filled with objects.

- Prevent Spread: Thanks to their special design, the booms can create an effective barrier to prevent the spread of chemicals to the surrounding environment. This is helpful when dealing with large and continuous chemical spills, protecting human health and limiting negative environmental impacts.

- Ease of Use: Chemical absorbent booms are designed for easy deployment and use, even in emergency situations. Users simply place the boom around the spill area, and it will automatically absorb and control the chemicals. The booms also have connecting hooks at both ends, allowing users to easily link multiple booms together to form a long barrier around a wide area.

- Variety in Sizes and Types: There are many types of chemical absorbent booms with different sizes and shapes, suitable for various usage needs. From compact booms for use in laboratories to large booms for extensive industrial areas.

3. Applications of Chemical Absorbent Booms

Chemical absorbent booms are widely used in many fields, including:

- Manufacturing Industry: To control spill incidents during the operation of machinery and equipment.

- Transportation Industry: Especially in the transport of hazardous goods and chemicals.

- Laboratories: To control spill incidents during experiments and research.

- Oil and Gas Industry: To prevent oil spills and petrochemical product spills.

Conclusion

The use of chemical absorbent booms is an effective and flexible solution for responding to chemical spill incidents. Not only do they help minimize damage and protect the environment, but they also provide peace of mind for businesses and workers when handling dangerous chemicals. Investing in chemical absorbent booms is not just a protective measure but also an essential part of every company’s safety and environmental protection strategy.

For more information on products and industrial cleaning solutions, please contact:

BIG NANO TECHNOLOGY

Hotline: (+84) 879 808 080 – (+84) 868 939 595

Email: sales@bignanotech.com